CHAPTER 3: SYSTEM CONFIGURATION

HF-2500A HIGH FREQUENCY WELD CONTROL

3-12 990-371

1. From the SETUP 1 screen, press the 2 key

to go to the SWITCH DE-BOUNCE TIME

menu screen.

2. Select the required debounce time by

pressing the 1, 2, 3 or 4 key. NONE

represents a debounce time of 0 ms.

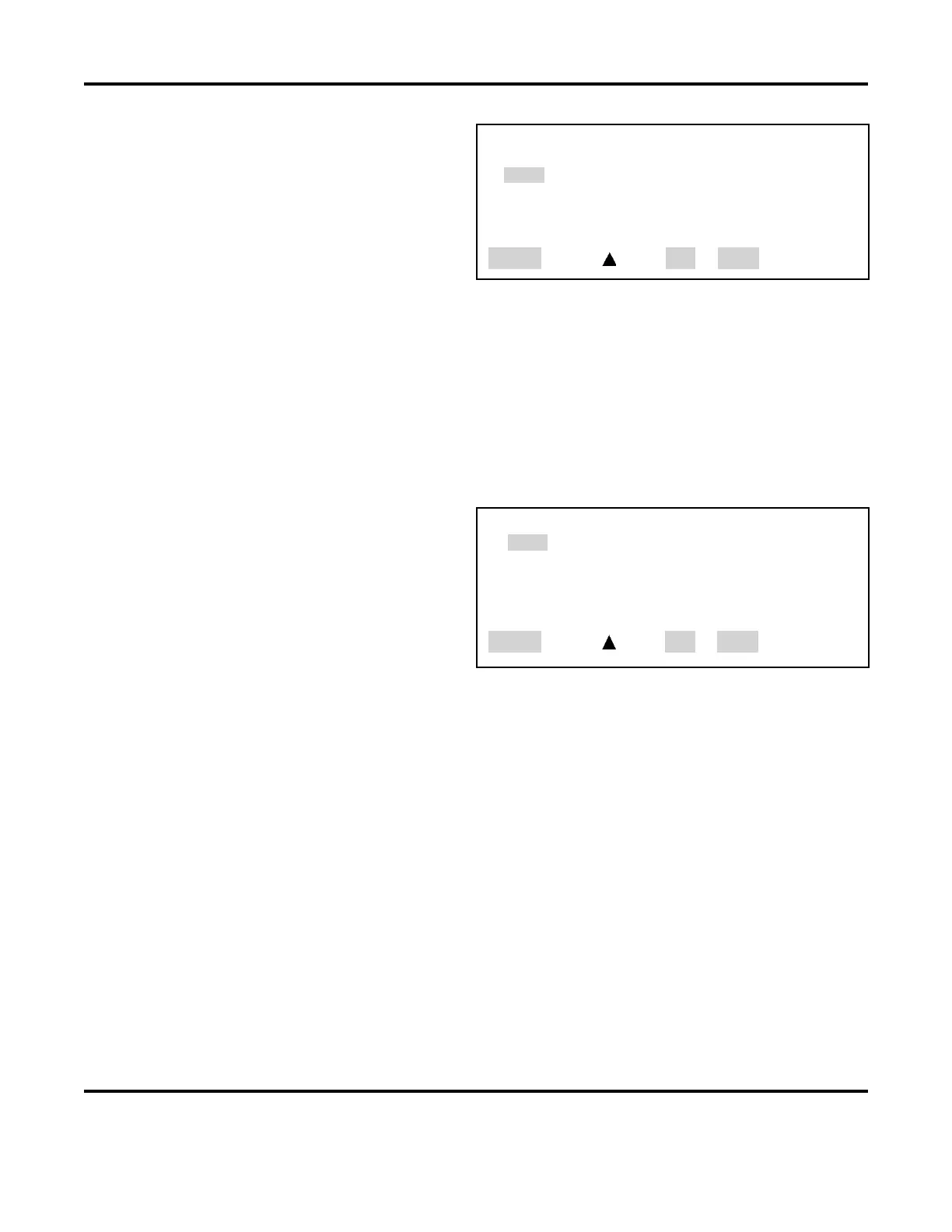

<SWITCH DEBOUNCE TIME>

1. NONE

2. 10 ms

3. 20 ms

4. 30 ms

Number Select, Page, RUN or MENU

Use NONE for interfacing with the AMADA WELD TECH SL-320A Electronic Weld Force

Control.

3. The SWITCH DEBOUNCE TIME line will now reflect your switch debounce time selection.

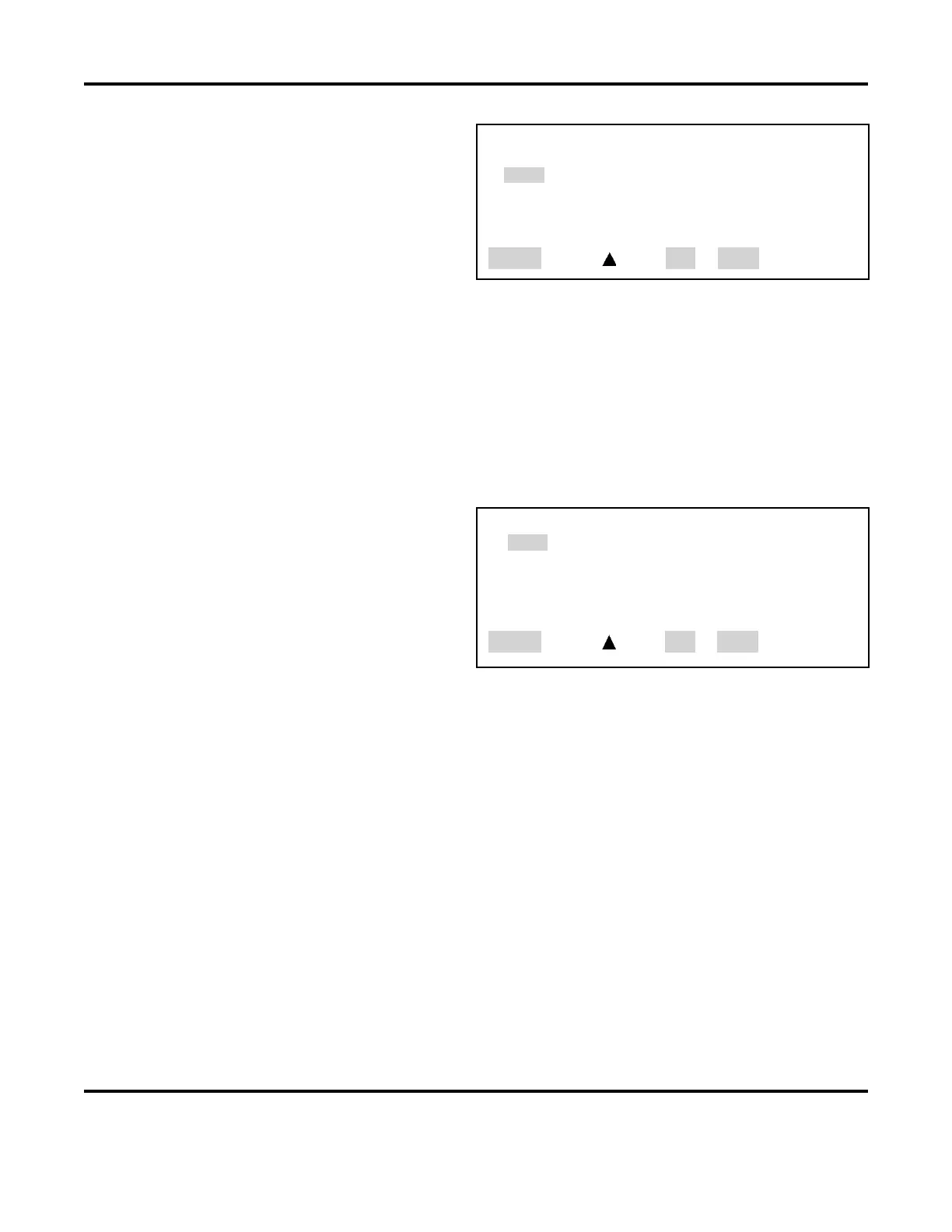

3. Firing Switch

With the SETUP 1 screen displayed, press the 3 key to select this function. The firing switch input, in

conjunction with or without inputs from the foot switch input, initiates the weld energy sequence. Select

the required switch type by pressing the 1, 2, or 3 key. Pressing the numeric keys automatically returns

the display to the SETUP 1 screen.

Power Supply accepts a single pole, double

pole or optical firing switch input from a

n

MADA WELD TECH weld head. Firing switch

activation indicates that the weld head has

reached the set weld force, thus permitting the

weld energy sequence to start.

<FIRING SWITCH>

1. AUTO

2. NONE

3. REMOTE

Number Select, Page, RUN or MENU

2. None

When using a non-force fired weld head, weld energy initiation must be supplied with the foot switch

input. Additionally, you must select sufficient squeeze time to permit the weld force to stabilize after

contacting the weld pieces.

3. Remote

Use this setting in an automation application or when using PLC control. The BCD input lines, via the

CONTROL SIGNALS connector (see Appendix B. Electrical and Data Connections), select weld energy

schedules and initiate the weld energy sequence.

Loading...

Loading...