CHAPTER 3: SYSTEM CONFIGURATION

HF-2500A HIGH FREQUENCY WELD CONTROL

3-16 990-371

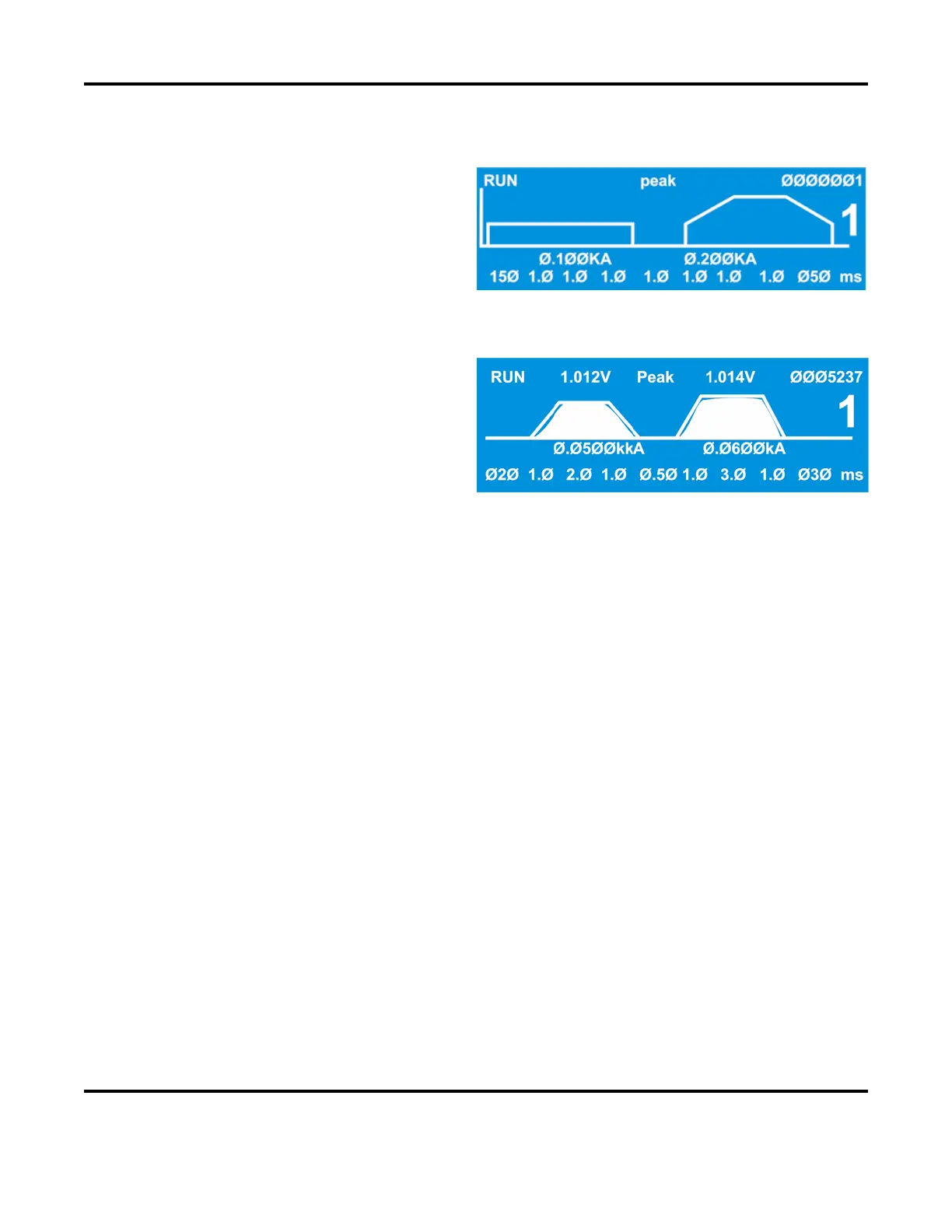

Run State

RUN

key puts the Power Supply in

the run state. In the run state, the screen shows a

trace that represents your programmed parameters

for a given weld schedule. You may select a

different weld schedule to be programmed with

the

SCHEDULE key and keypad, or with the up and

down arrows. Then, you may program squeeze

time, up slope, weld time, weld energy, down slope and cool time with the trace segment selector keys.

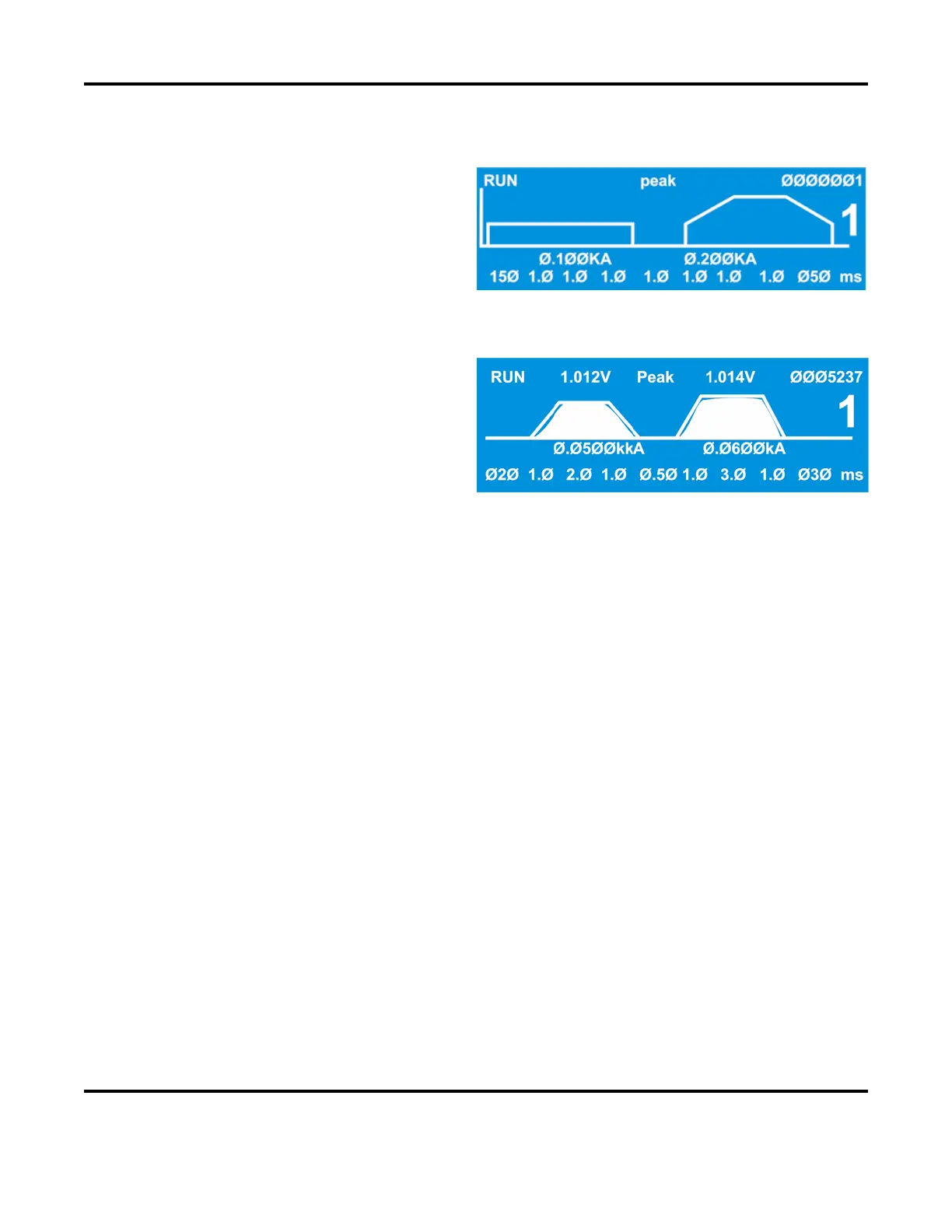

In the example on the right, the top line of the

screen shows that the

Power Supply is in the RUN

ltage at the voltage sense lead

PULSE 1 weld period was

volts, the monitor is set for displaying peak

voltage (rather than average voltage), the voltage

at the voltage sense input

connection for the

PULSE 2 weld period was 1.014 volts, and the total

weld count since the weld counter was last reset is 5,237.

The weld profile trace is an analog display of the electrical parameters programmed with the weld period

selector keys. When the weld is initiated, a profile of the actual weld energy delivered during the weld

cycle, or both weld cycles, will be overlaid on the trace.

The large-type number 1 is the selected weld schedule.

The values

0.050 kA and 0.060 kA below the trace are respectively the weld current values programmed

for

PULSE 1 and PULSE 2 weld periods. You may optionally program weld energy in volts or kilowatts

with the energy units selection keys.

Use the time/energy selector keys to toggle between the weld energy value field and the bottom line of

text, which is the weld period time selection field. Use the weld period selector keys to enable the weld

periods for programming, and use the numeric pad keys for entering time values in milliseconds.

See Chapter 5, Operating Instructions for application-related descriptions of the weld schedule profile.

Loading...

Loading...