CHAPTER 6: MAINTENANCE

HF-2500A HIGH FREQUENCY WELD CONTROL

6-2 990-371

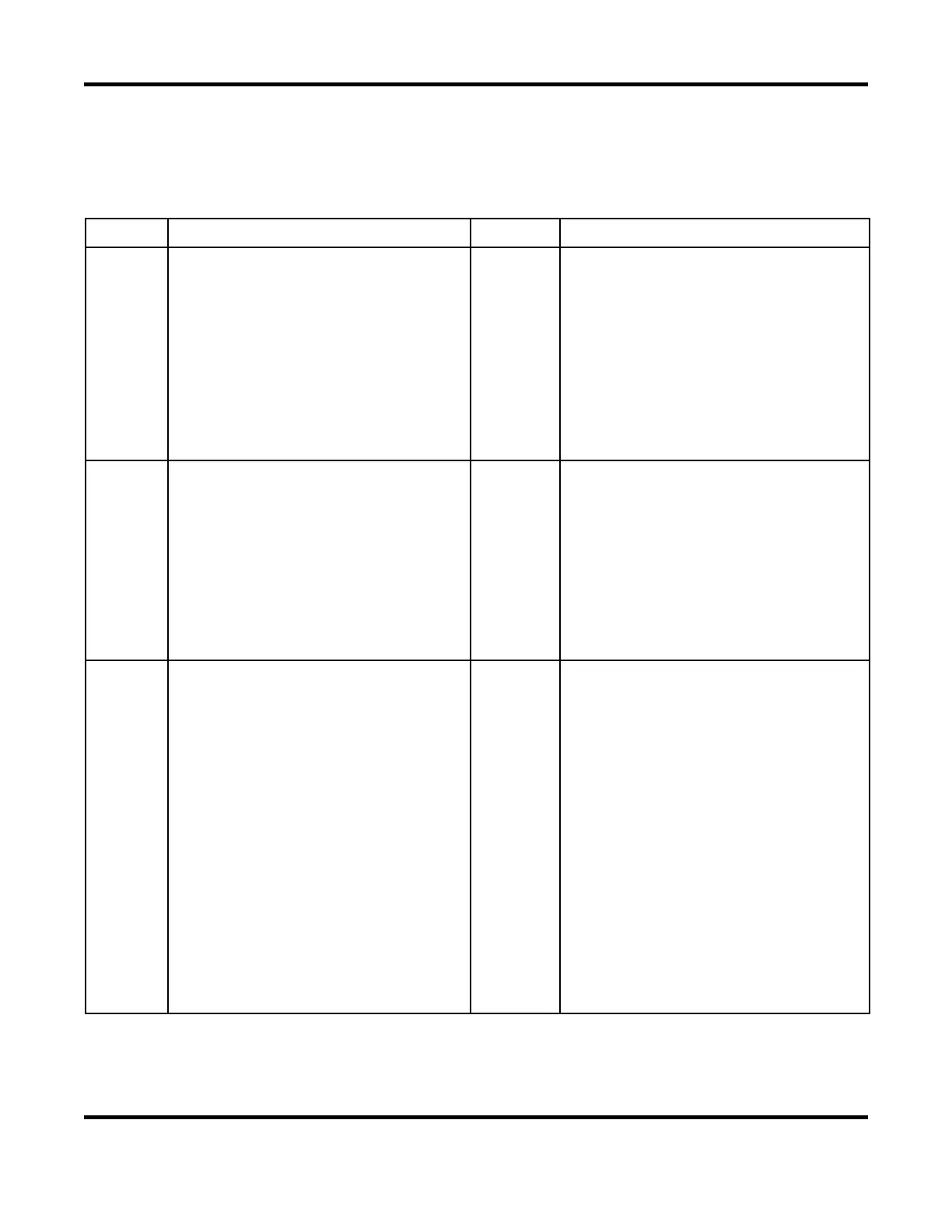

Section II. Troubleshooting

Troubleshooting

Problem Cause (in order of probability) Problem Cause (in order of probability)

Electrode

Damage

1. Excessive current/energy set at HF-

2500A

1.

Excessive or insufficient weld head

force

1. Wrong electrode tip shape

2. Excessive weld time set at HF-2500A

2.

Contaminated weld piece surface/

plating

2. Wrong electrode material

2. Contaminated electrode surface

Electrode

Sparking

1. Excessive current/energy set at HF-2500A

1. Insufficient weld head force

1. Slow weld head follow-up

1.

Incompatible weld piece projection

design

1. Contaminated weld piece surface/ plating

1. Wrong electrode tip shape

2. Wrong electrode material

2. Contaminated electrode surface

Electrode

Sticking

1.

Contaminated weld piece surface/

plating

1. Wrong electrode material/ tip shape

1. Insufficient weld head force

2. Excessive current/energy set at HF-

2500A

2. Excessive weld time set at HF-2500A

2. Contaminated electrode surface

3. Slow weld head follow-up

Weld Piece

Warping

1. Excessive weld time set at HF-2500A

1. Excessive weld head force

1.

Incompatible weld piece projection

design

2. Incompatible weld piece materials

2. Wrong electrode tip shape

3. Excessive current/energy set at HF-2500A

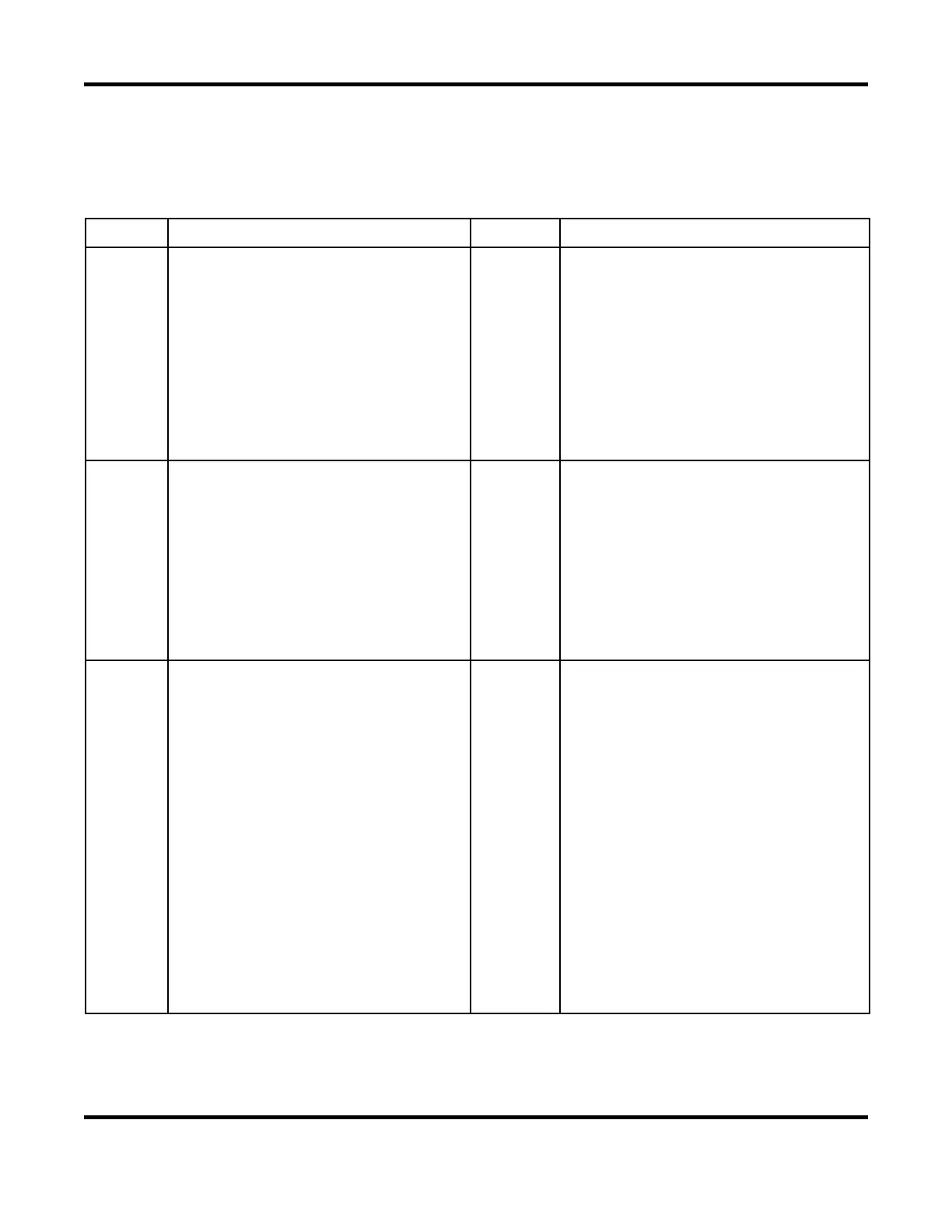

Insufficien

t Weld

Nugget

1. Insufficient current/ energy set at HF-

2500A

1. Wrong electrode material/ tip shape

1. Worn/mushroomed electrodes

2. Insufficient weld time set at HF-2500A

2. Incorrect weld head polarity

2.

Contaminated weld piece surface/

plating

2. Excessive weld head force

3. Insufficient weld head force

3. Contaminated electrode surface

3.

Incompatible weld piece projection

design

3. Slow weld head follow-up

4. Incompatible weld piece materials

4. No cover gas on weld piece

Metal

Expulsion

1. Excessive current/energy set at HF-2500A

1. Insufficient weld head force

1. Slow weld head follow-up

1.

Incompatible weld piece projection

design

2. Contaminated weld piece surface/ plating

2. Incompatible weld piece materials

2. Contaminated electrode surface

2. Wrong electrode tip shape

3. No cover gas on weld piece

4. Excessive weld time set at HF-2500A

Loading...

Loading...