CHAPTER 3: SYSTEM CONFIGURATION

HF-2500A HIGH FREQUENCY WELD CONTROL

990-371 3-23

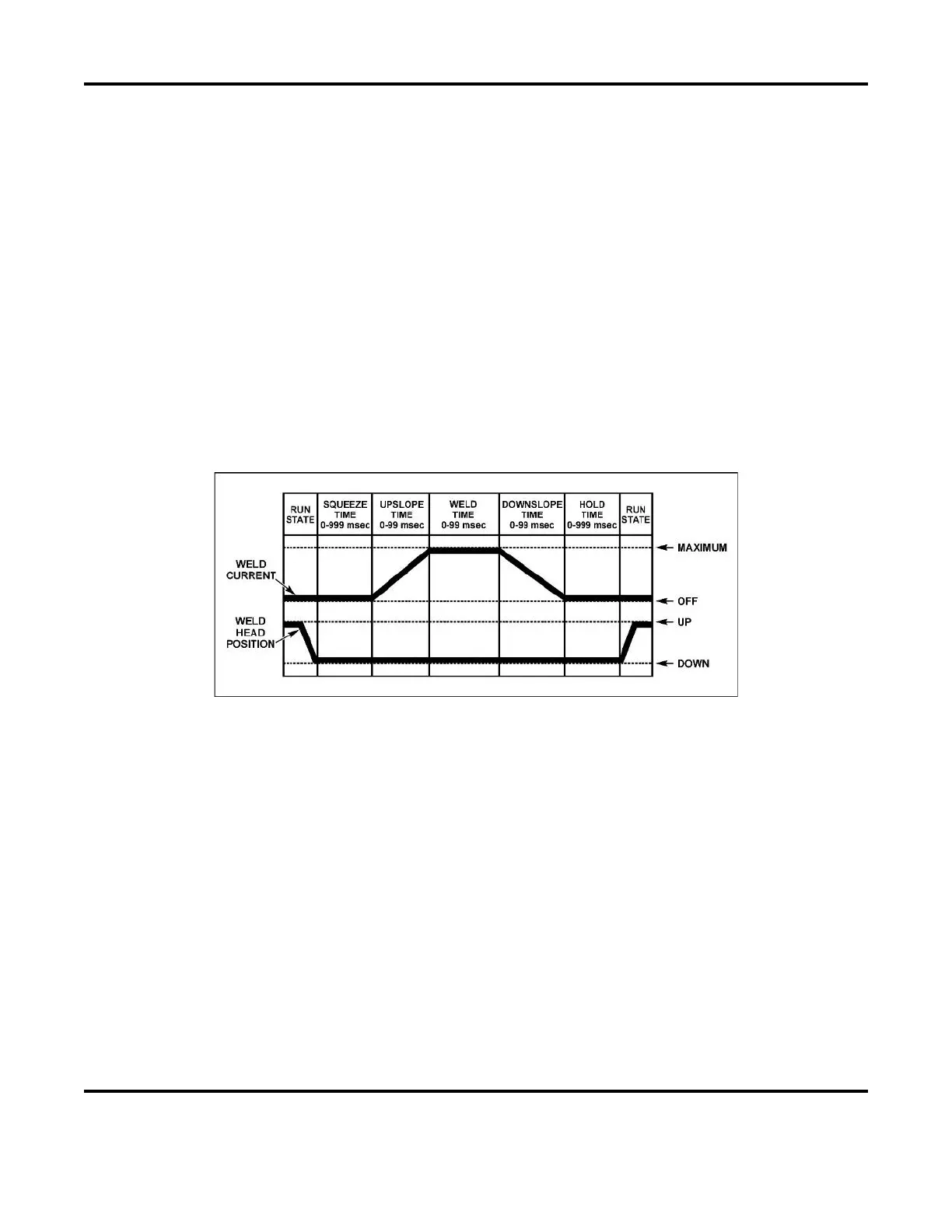

Upslope/Downslope Weld Profile

Applications

• Round or non-flat parts and most resistive materials.

Description

Upslope allows a gradual application of weld energy which permits the parts to come into better

contact with each other reducing the electrode to part contact resistances. Upslope can allow a smaller

electrode force to be used, resulting in a cleaner appearance by reducing electrode indentation,

material pickup and electrode deformation. It can also be used to displace plating and/or oxides,

reduce flashing and spitting, or reduce thermal shock when welding parts containing glass-to-metal

seals.

Downslope (annealing) assists in the grain refinement of certain heat-treatable steels, and prevents

cracking in aluminum and other materials by reducing the cooling rate. Annealing is not typically

used for welding small parts.

Upslope / Downslope Weld Profile

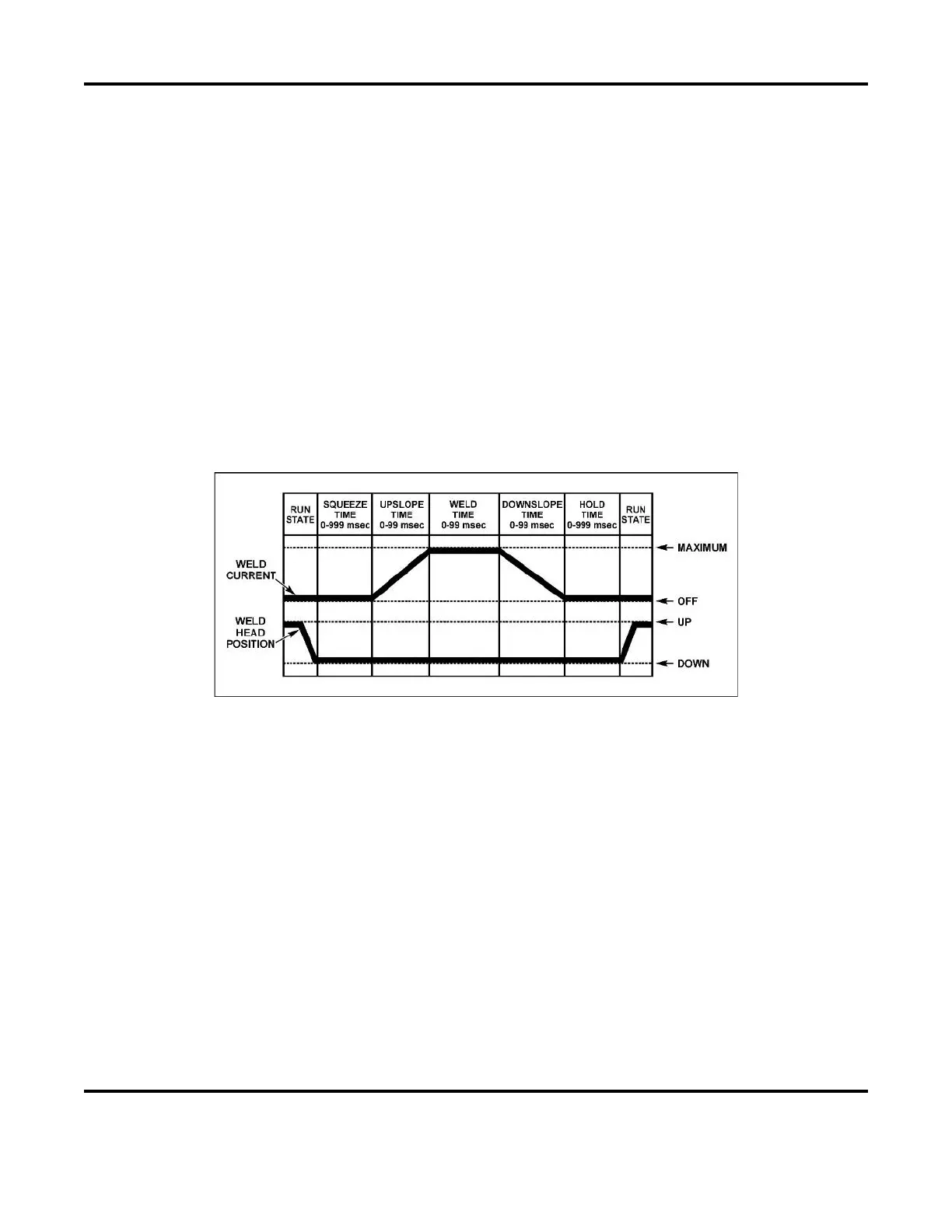

Dual-Pulse Weld Profile

Applications

• Flat-to-flat parts.

• Round-to-round parts.

• Round-to-flat small parts that may or may not be plated.

Description

Adding upslope to the front of both weld periods allows a reduction in electrode force, this results in

a cleaner appearance by reducing electrode indentation, material pickup and electrode deformation.

Loading...

Loading...