CHAPTER 4: INTRODUCTION TO FEEDBACK MODES AND MONITORING

HF-2500A HIGH FREQUENCY WELD CONTROL

4-2 990-371

Section II. Weld Monitoring

Introduction

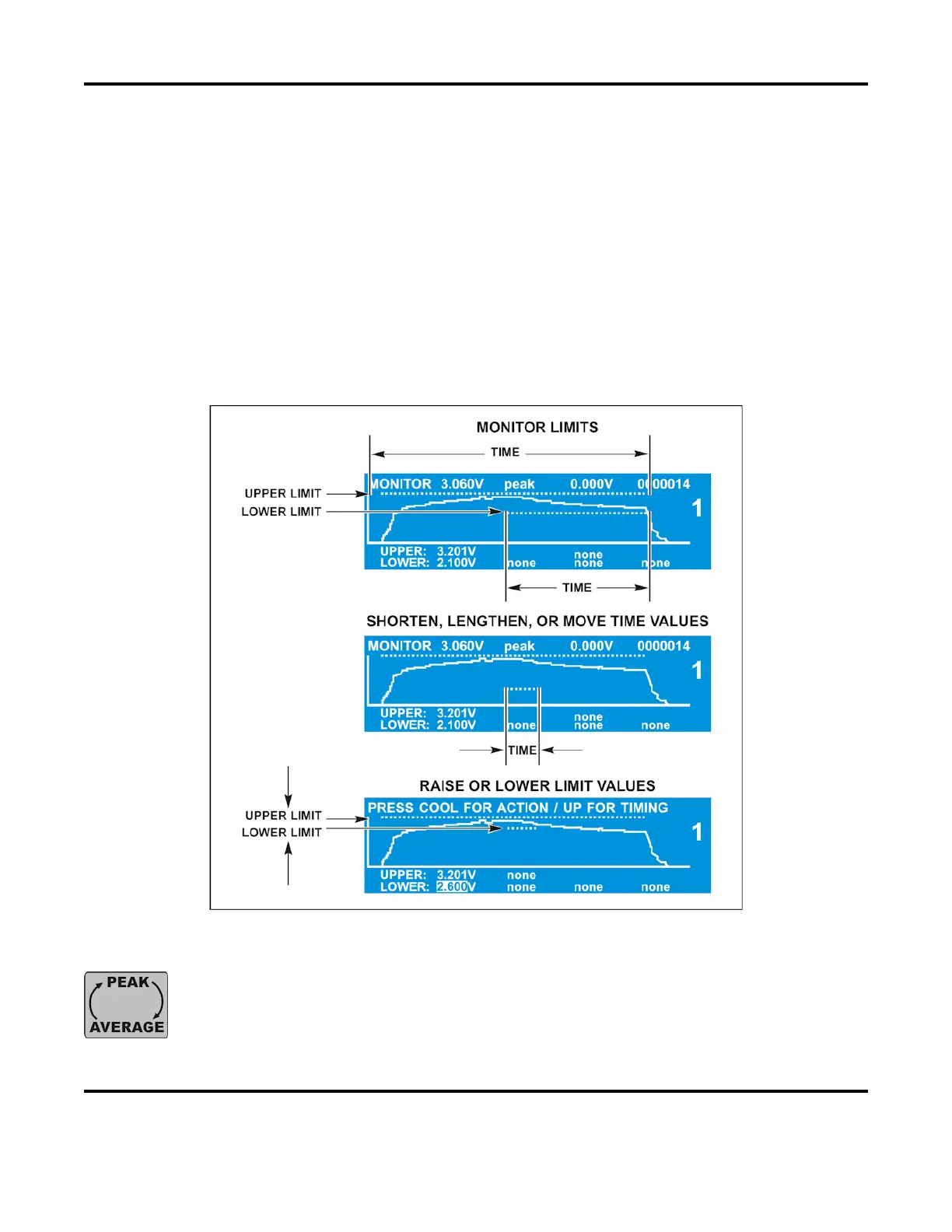

The Power Supplies feedback sensors not only control weld energy output, but they can also be used to

monitor each weld. The Power Supplies MONITOR features allow you to view graphic representations of

welds, visually compare programmed welds to actual welds, look at peak or average energy values, set

upper and lower limits for welds, and vary the time periods for these limits during the weld pulse. These

limits can be used for several purposes. Common uses for out-of-limits welds are to stop a weld, or to

trigger a relay to remove parts with bad welds from the production line. These functions are accessed

using the MONITOR buttons on the front panel. To use these functions, see Chapter 5, Operating

Instructions.

PEAK and AVERAGE MONITORING

The Power Supply is always monitoring both the

PEAK

AVERAGE

of current, voltage,

power, and resistance at the same time. When you press the

PEAK ↔ AVERAGE key,

the top line in the LCD simply toggles back and forth so you can

view either PEAK or

AVERAGE values whenever you choose.

Loading...

Loading...