CHAPTER 5. OPERATING INSTRUCTIONS

HF-2500A HIGH FREQUENCY WELD CONTROL

990-371 5-15

Section V. Resistance Set

NOTE: The Resistance Set tool is very similar to the Active Part Conditioning tool. The difference is

that the first pulse is programmed as all Upslope for Resistance Set, where it is programmed as all Weld

Time (Square Wave) for Active Part Conditioning. The Resistance Set pulse is programmed as all

Upslope to keep both the Voltage and Current low at the beginning of the pulse.

SCHEDULE

key, then select a Weld Schedule using either the ▲▼ arrows or

the numeric keypad.

Program a single pulse for Constant Power operation, but program the time in the Upslope

portion of Pulse 1

. Program the Weld Time and Downslope of Pulse 1 to 0.0 ms.

Program the

power level and

Upslope

time to cause slight sticking between the two parts. Make a few welds

and pull them apart. Increase or decrease the power setting until a light tack weld is

achieved.

From the MONITOR keys section on the front panel, press the voltage V key and observe

gradual rise of the voltage waveform.

MONITOR

keys section on the front panel, press the Ω (resistance) key and

observe the resistance waveform. This should appear to begin high, then start to drop as

a tack weld is made and the resistance decreases.

From the MONITOR keys section on the front panel, press the kA (current) key and observe

the current waveform starting to rise as the resistance decreases

. If the current waveform

starts to flatten, this is an indication that the resistance has stabilized and the parts have

come into closer contact.

Push RUN and optimize the energy and time setting of Pulse 1 to provide an adequate tack

weld and also a current waveform (view in the monitor screen) that has started to flatten

out, but is still rising. This indicates that a full melt has not yet occurred.

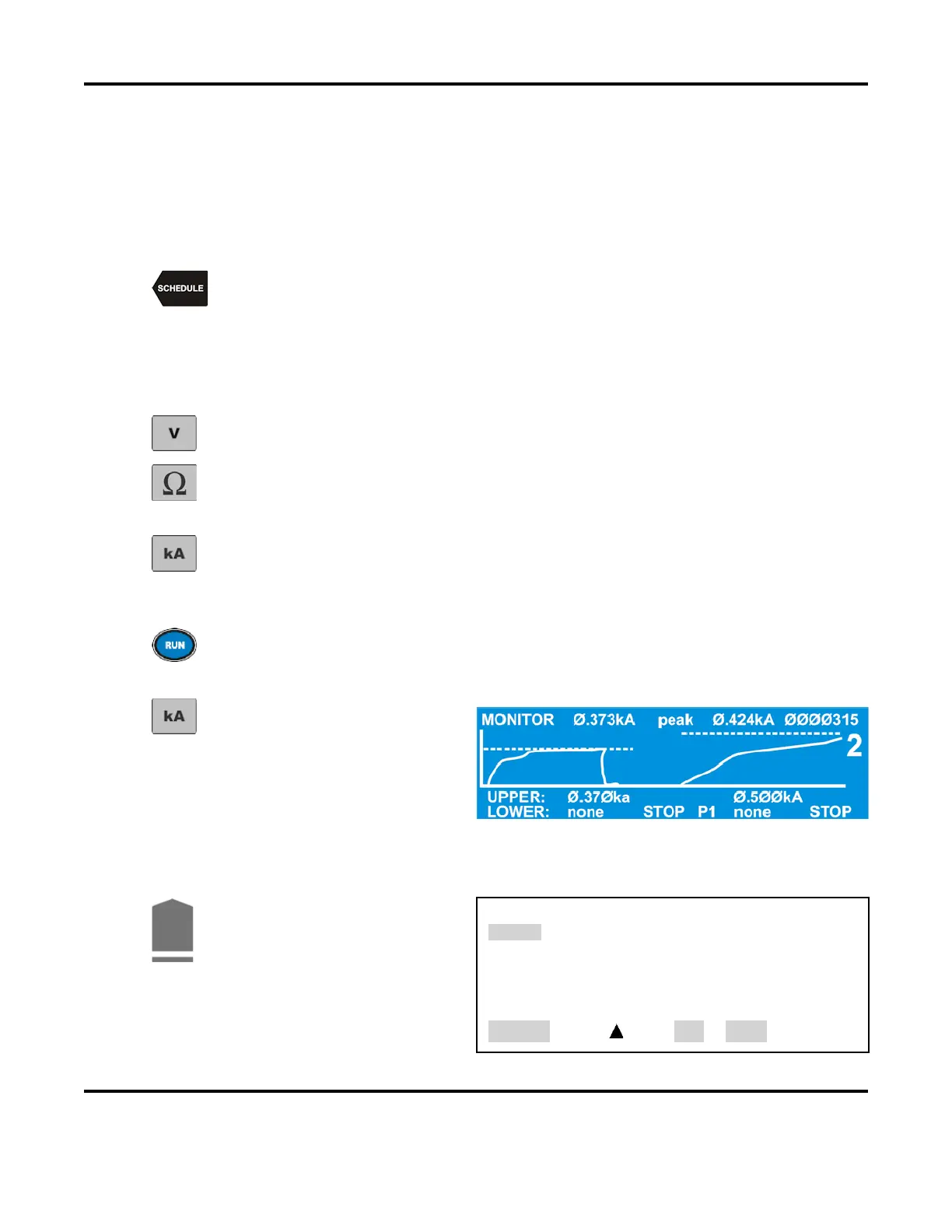

From the MONITOR keys section

on the front panel, press the kA

key to program an upper current

limit on the MONITOR screen.

NOTE: You can toggle between PEAK and AVERAGE readings by pressing the

PEAK/AVERAGE key.

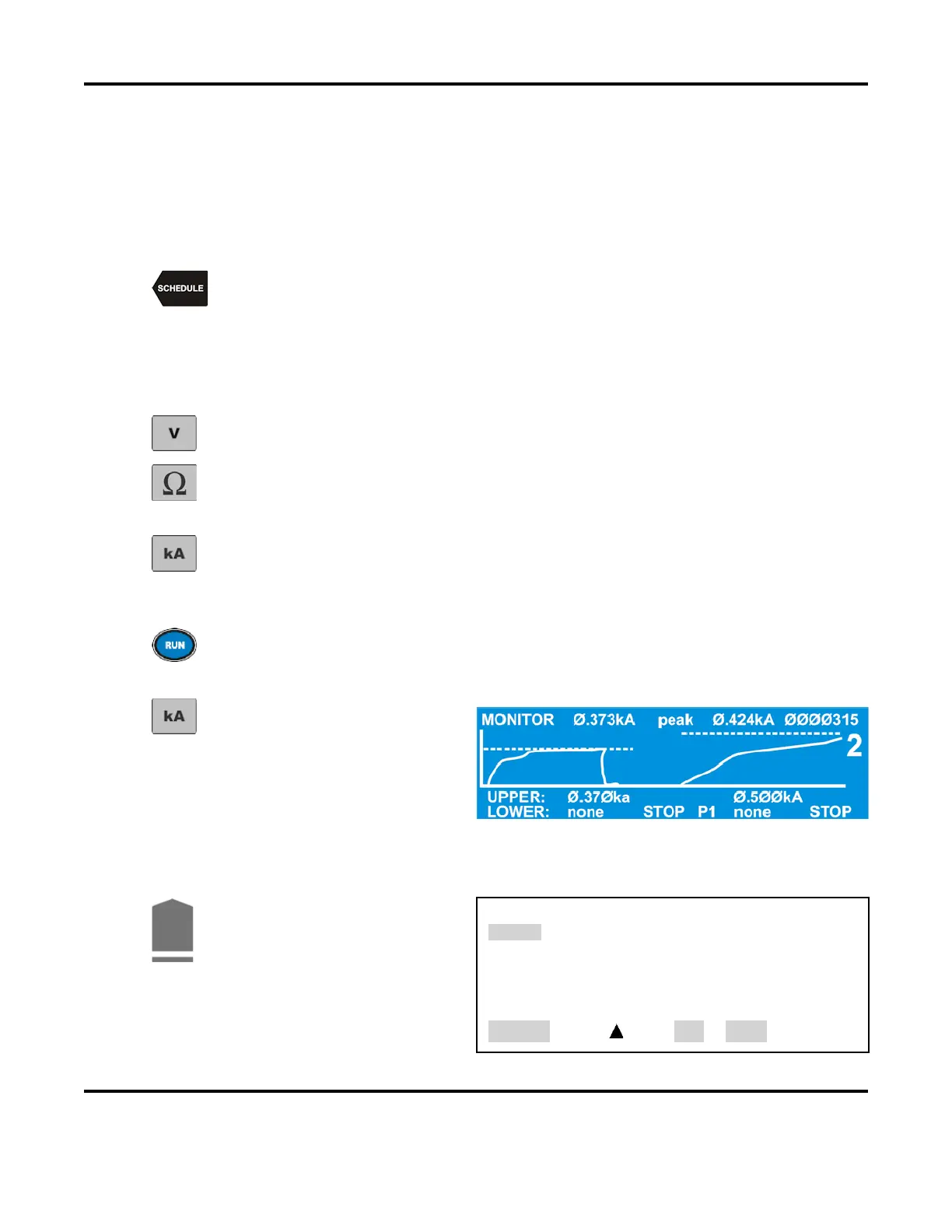

Press the COOL weld period key.

This will bring up the PULSE 1

OUT OF LIMITS ACTION

screen.

Select 4.

(Stop PULSE1).

PULSE 1 OUT OF LIMITS ACTION

1. none

2. STOP WELD

3. INHIBIT PULSE 2

4. PART CONDITIONER (Stop Pulse1)

NUMBER Select, Page, RUN or MENU

Loading...

Loading...