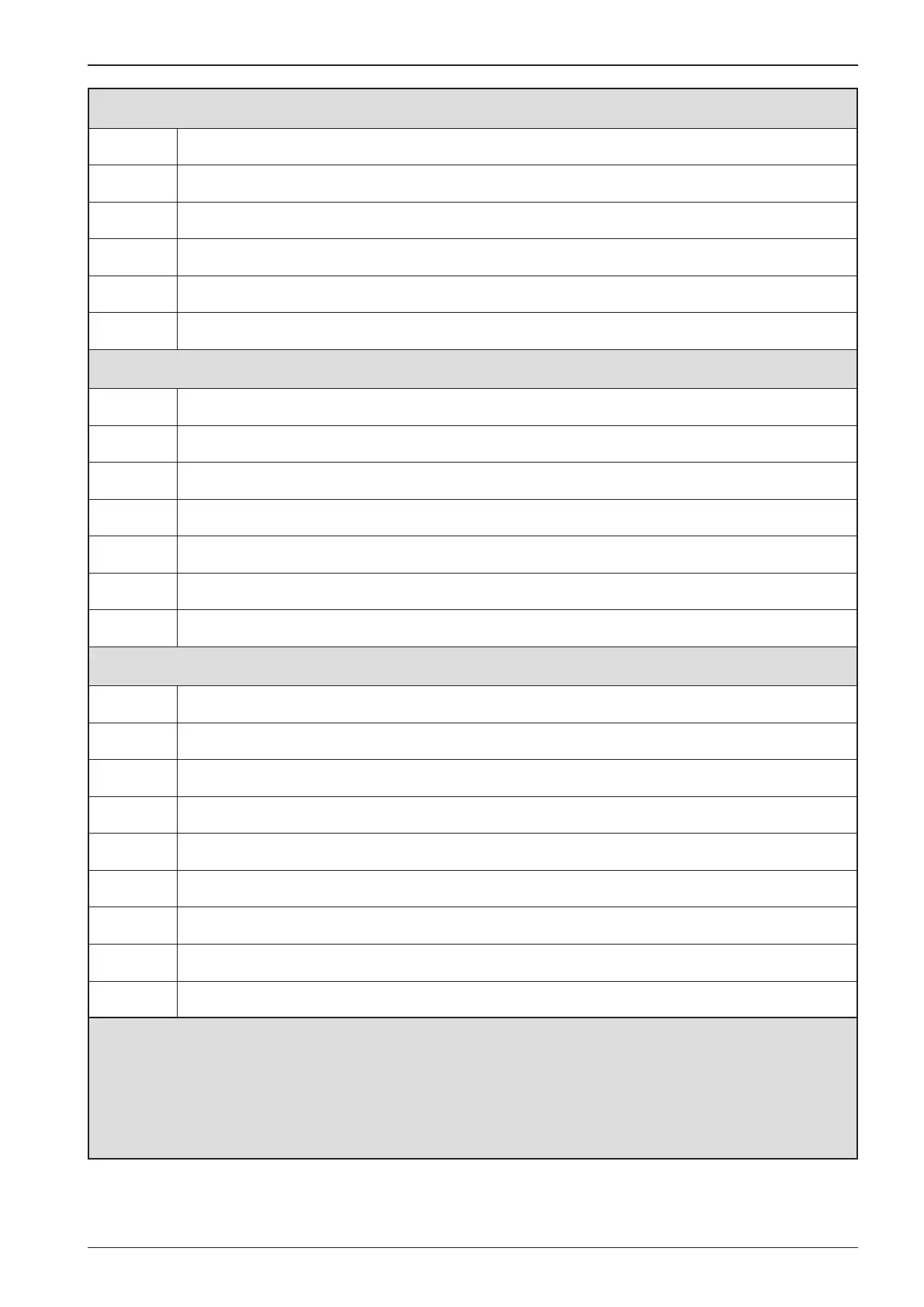

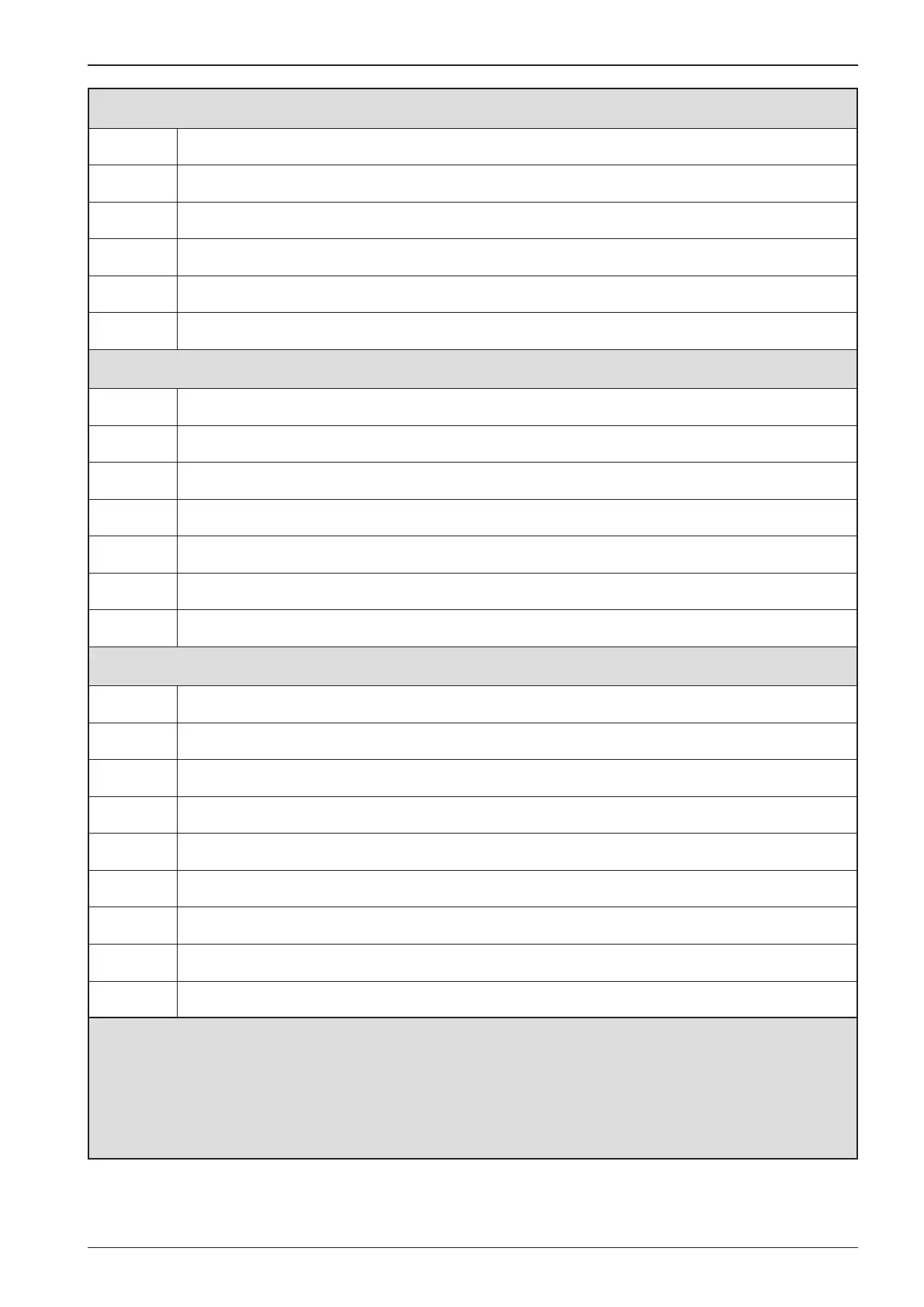

95AP 240

After 1000 hours of operation (1 year)

3.6.22. Check and adjust brake clips

3.6.23. Hydraulic Accumulator

3.6.24. Checking the engine belt

3.6.25. How to exchange CLARK gearbox oil

3.6.26. How to replace nal drive oil ***

3.6.27. How to replace air drier

After 2,000 hours of operation (after 2 years)

3.6.28. Check, adjust valve clearance

3.6.29. How to exchange oil in rear axle ***

3.6.30. How to exchange hydraulic oil and lter

3.6.31. How to exchange oil in hydraulic cylinders for front axle

3.6.32. How to exchange brake uid

3.6.33. Exchanging the engine cooling liquid

3.6.34. Check the compressor *

Maintenance if required

3.6.35. Fuel Pre Cleaner – Water Separator

3.6.36. How to deaerate fuel lter

3.6.37. How to replace air lter elements

3.6.38. Cleaning of coolers

3.6.39. Clean sprinkling lter

3.6.40. Clean brush scrapers

3.6.41. Cleaning the air cleaner of cabin ventilation

3.6.42. Clean the Machine

3.6.43. Conrm bolt connections are tightened

First after 50 hours - Make single check to conrm wheel nuts are tightened to 400 Nm (295 lb ft) torque

* First after 50 hours

** First after 100 hours

*** First after 250 hours

Loading...

Loading...