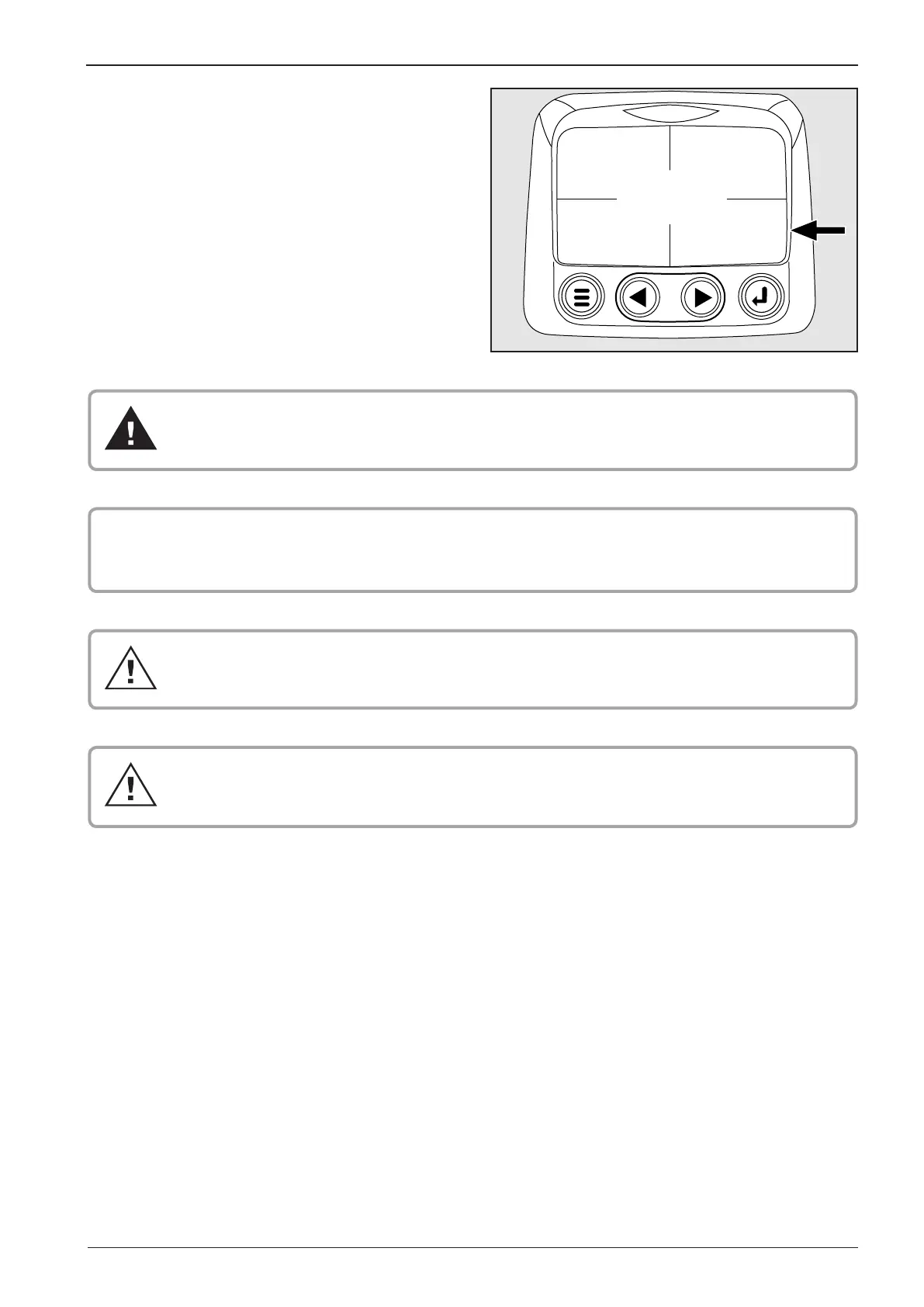

20%

FUEL LEVEL

100

ENG HRS

28°C

COOL TEMP

0 RPM

ENG RPM

396313A

Carry out lubrication and maintenance in regularly repeated in-

tervals as per the everyday data reading on the counter of hours

actually worked.

3.6. Lubrication and Maintenance Operations

Carry out maintenance with the Machine placed on at, paved surface, and secured against any self-

motion, always with the engine OFF, key removed from ignition box, and with the wiring disconnected

(unless otherwise required).

! CAUTION !

Removed or loose bolts, plugs, threaded joints of the hydraulics, etc. shall be tightened with the torque according

to the Tables in Section 3.6.43., unless a dierent value is given with the relevant operation.

This Manual includes only the basic information about the engine, other information is given in the

“Cummins Engine Operation and Maintenance Manual” which is part of documentation supplied with

the Machine.

Following the rst 50 hours of operation of the new Machine (after Major Overhaul), please perform the following:

Make single check to conrm wheel nuts are tightened to 400 Nm (295 lb ft) torque

Following the rst 50 hours of operation of the new Machine (following a major overhaul) carry out as per:

3.6.34. Check the compressor

Following the rst 100 hours of operation of the new Machine (following a major overhaul) carry out as per:

3.6.19. How to replace CLARK gearbox oil lter

Following the rst 250 hours of operation of the new Machine (following a major overhaul) carry out as per:

3.6.26. How to replace nal drive oil

3.6.29. How to exchange oil in rear axle

Have the air tank inspected by a specialized service company no later than every 5 years. Make sure the

inspection date and the service engineer sign are marked on the label. NO welding or heat treatment

are admissible on the air tank. The air tank life is max 40 years, it shall be discarded afterwards.

Loading...

Loading...