3.6. Lubrication and Maintenance Operations

With brake shoe lining replaced the

brake eciency will lower and stopping

distance will get longer. Adapt driving

mode and braking mode to this case!

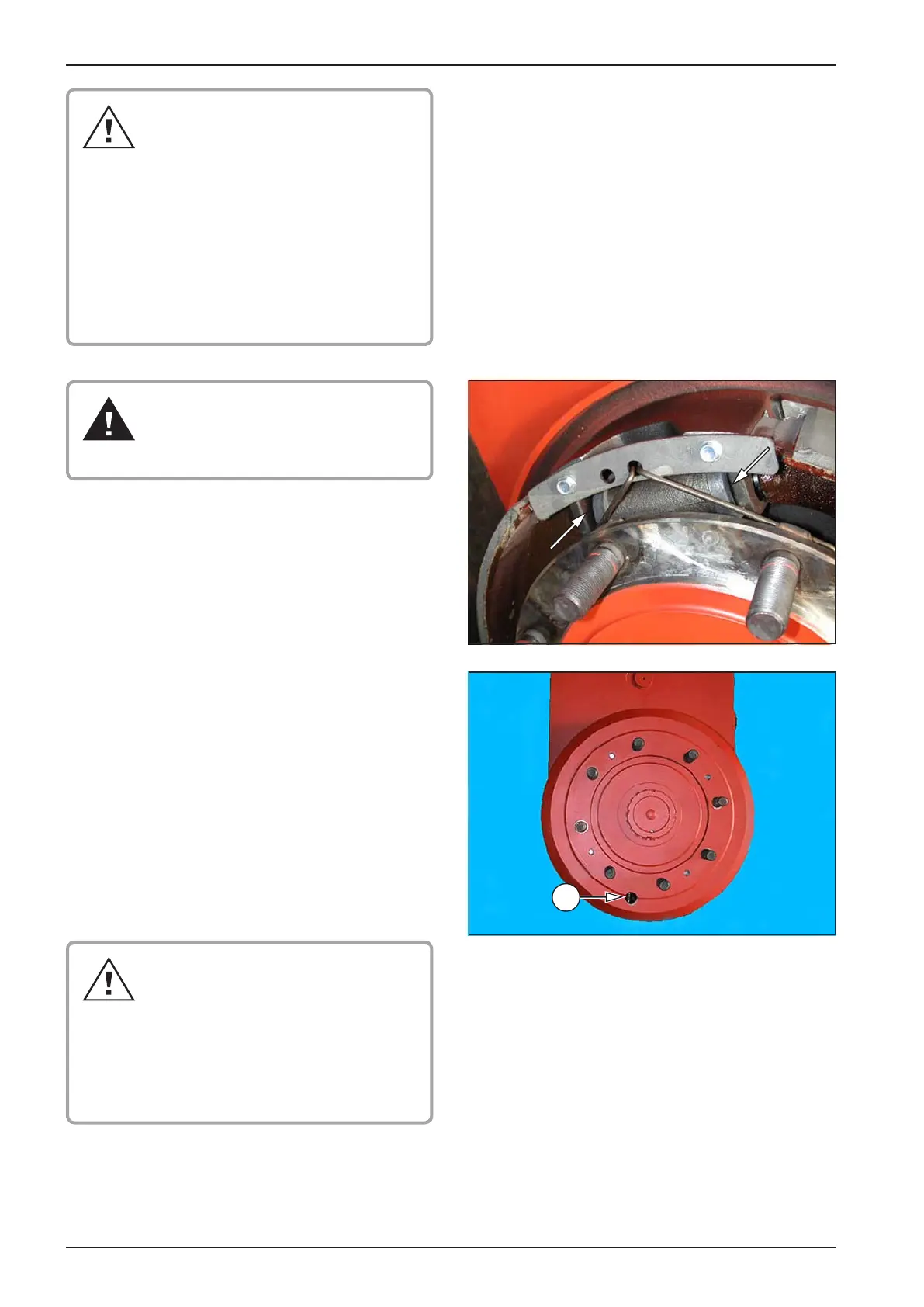

Check brake cylinder for any leakage of brake uid.•

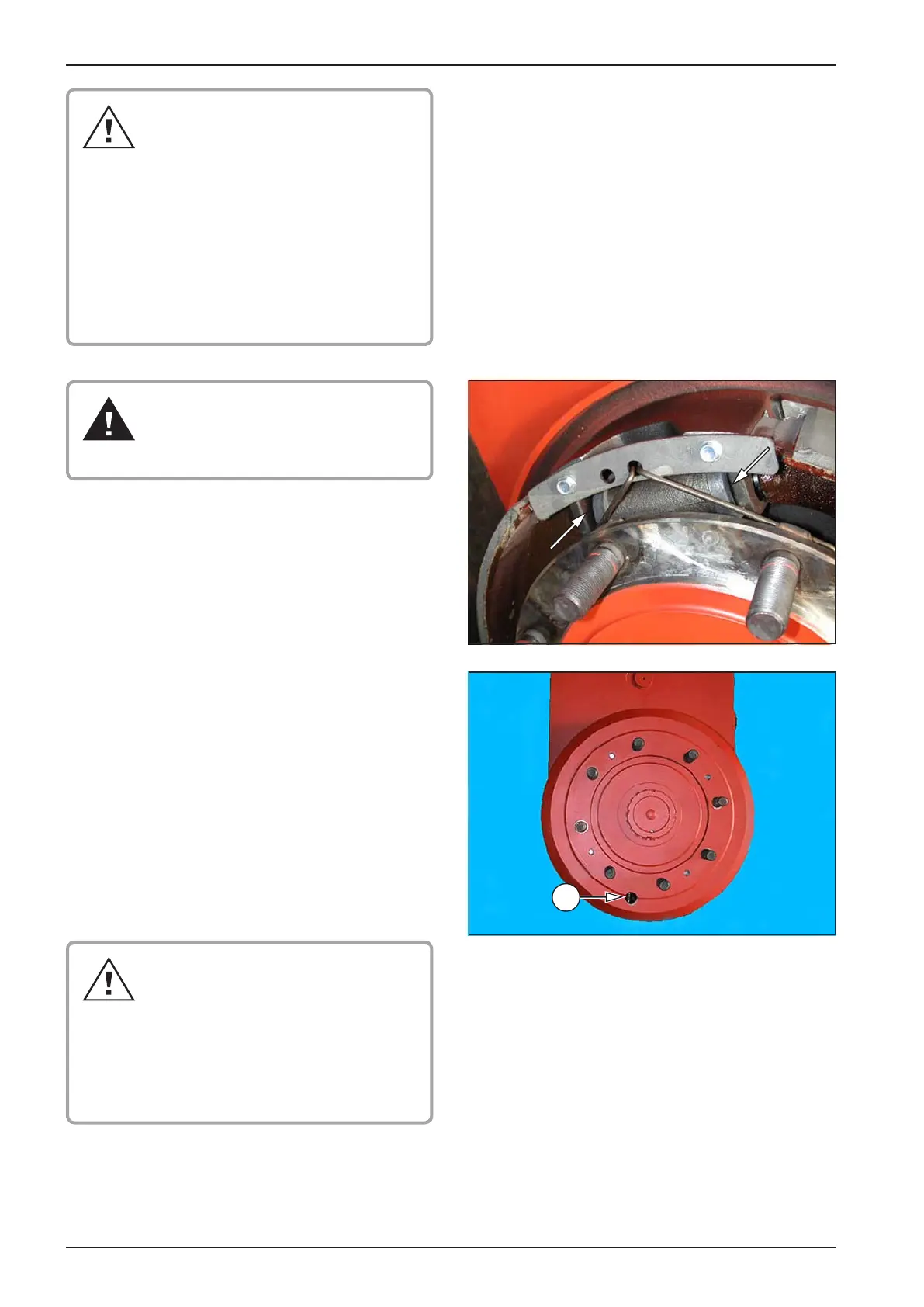

When checking is completed reinstall the drums. Turn brake •

drum with its adjustment hole pointing downward towards

adjusting wheel. Rotate adjusting wheel (1) until brake clips

lean against brake drum (brake drum unable to rotate). Turn

a bit the adjusting screw backward by only such turn so the

brake clips get released (brake drum able to rotate freely).

Carry out brake clip adjustment during:

Insucient brake eciency (long step of

brake pedal)

Replacement of worn clips for new ones

Following the installation of new brake

drum or after brake drum’s inner diam-

eter is machined (refer to Workshop

Service Manual).

If, while checking, you nd lining thick-

ness is 4 mm (0,16”) or smaller, please

check lining after next 500 operating

hours.

Replace lining always when thickness

reaches min value of 2 mm (0,08”).

Replace all brake clips at one time to

maintain uniform braking!

Always replace adjusting mechanism de-

fected with new one.

When replacing, use original brake clips

only!

Before installing wheels onto the brake drums following the •

brake repair, please point the brake drum bolts against holes

in the wheels using an appropriate lever so to avoid damage

of bolt threads, reinstall wheels, tighten wheel nuts with 400

Nm (295 lb ft) torque.

Loading...

Loading...