3.6. Lubrication and Maintenance Operations

Fill equalizer tank with uid and keep level above ”MIN” •

when deaerating.

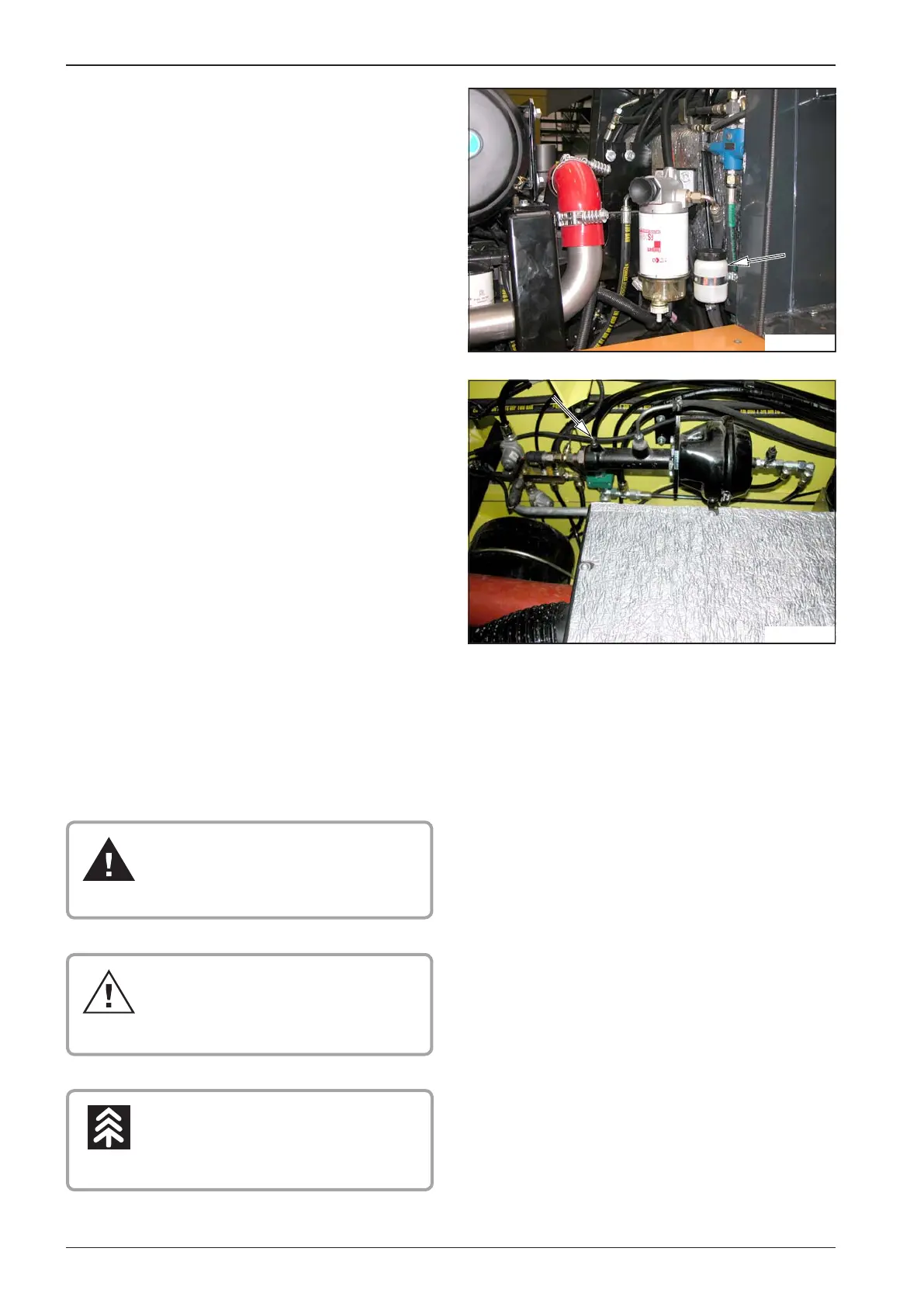

Slacken deaeration screw at the brake master cylinder by 2 •

turns, and when lled up with uid, close deaeration screw.

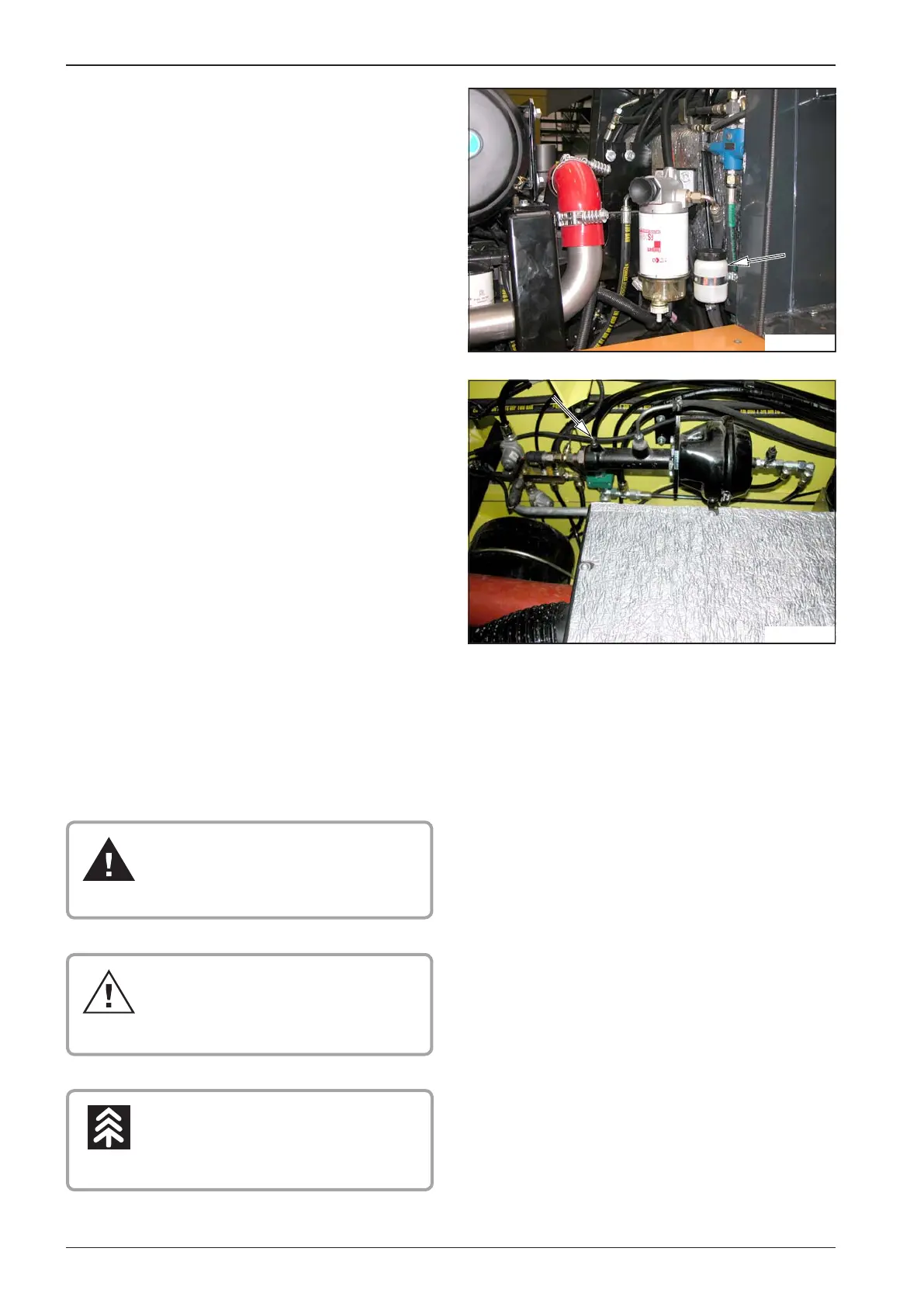

Fill tanks with new brake uid (immerse hose pipe end •

below level). Slacken deaeration screws. Press brake pedal

slowly as long as uid moves out with air bubbles. Then with

the brake pedal pressed, close deaeration screws for brake

cylinders, wipe them and install protective caps. Check cir-

cuit tightness, level in the tank, and adjust. Reinstall wheels.

Tighten wheel nuts with 400 Nm (295 lb ft) torque.

Keep brake uid inside original, well

closed containers! When in use, pro-

ceed according to brake uid producer’s

instructions.

Brake uid will damage painted parts of

the Machine.

Use recommended brake uid under

Section 3.2.3.

When lling up, avoid uid spilled over

the Machine and o the Machine as well.

Collect brake uid in the vessel and hand

it over for disposal!

Loading...

Loading...