3.6. Lubrication and Maintenance Operations

Flush the system:

Follow Engine Operation and Maintenance Manual to ush •

the system during replacement, using mixture of water and

soda (sodium carbonate) in the ratio of 0,5 kg (1.1 lb) of soda

per 23 l (6.0 gal US) of water. Fill up the system with such

mixture and warm up to 80 °C (176 °F) with the engine run-

ning – do NOT install pressure closure for equalizer tank.

Shut o the engine and drain water, ll with new water and

warm up the engine, d drain water again. Repeat this until

water is clean.

Start the engine and wait until temperature reaches 80 °C •

(176 °F). Then stop the engine. At the same time check that

no cooling liquid is leaking. Check level in equalizer tank,

make up to MAX.

Before lling up, let temperature drop

below 50 °C (122 °F). When plug is

opened there is hazard liquid will splash

out followed by scald hazard.

Follow anti-freeze producer’s instruc-

tions when exchanging anti-freeze!

Drain liquid into collection vessel!

Hand over spent liquid for safe disposal

in line with regulations!

Use anti-freeze according to Section

3.2.3.!

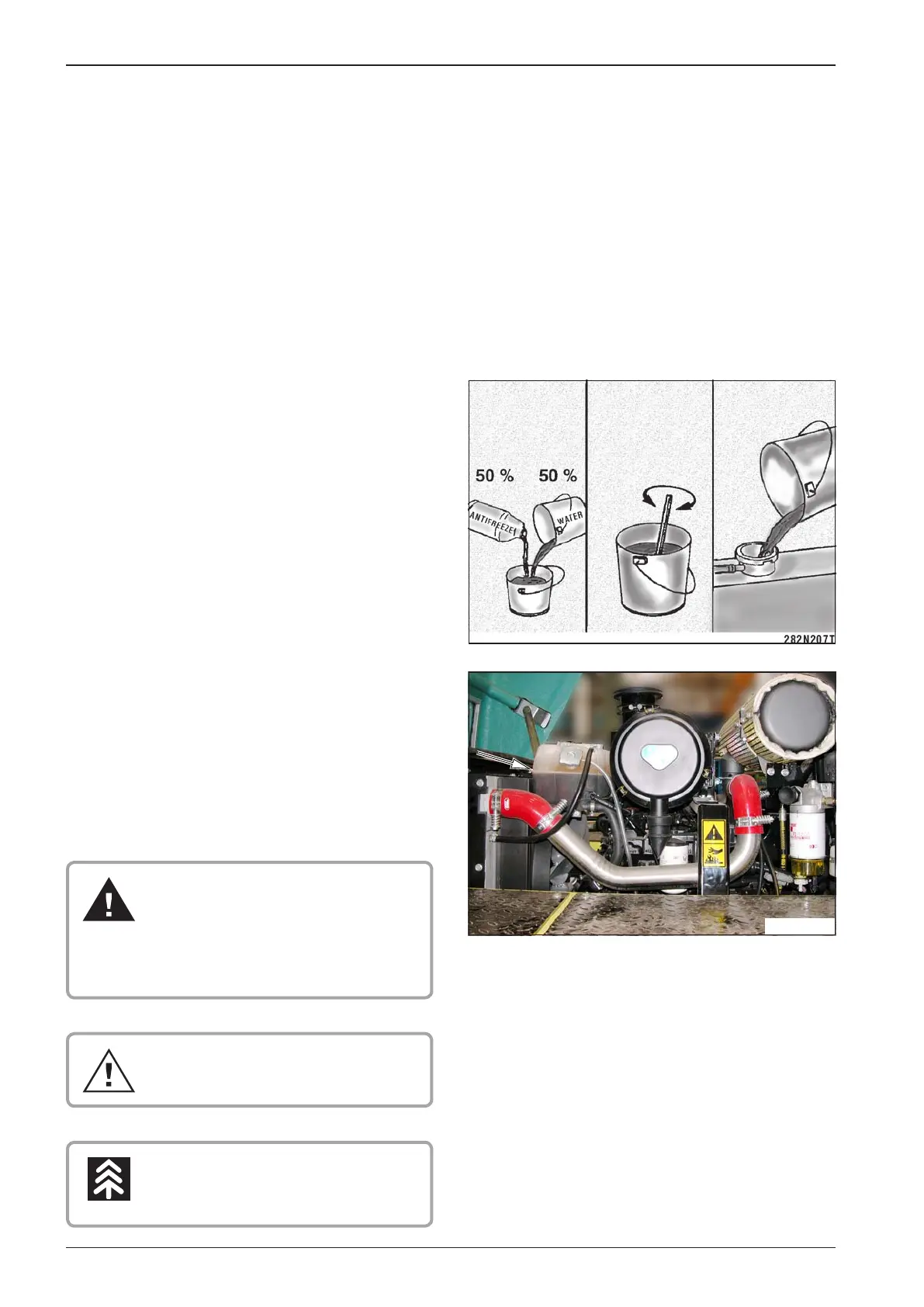

Fill cooling system with new cooling liquid in the ratio of •

50 % water + 50 % antifreeze agent between MIN and MAX.

Max. lling speed is 10 l/min (2,6 gal US per minute). Use the

lid to close equalizer tank.

Loading...

Loading...