C Motor pump power cable

MP Motor pump terminal

B Blue

M Brown

GV Yellow-green

C

MP

B B

M M

GV GV

3.4 Wiring

It is necessary to link a safety main

switch (A) on the electric panel, as

required by standard regulations.

Machine with INTERNAL MOTOR PUMP

In case of internal motor pump connect the power

cable as set forth in the chapter "Electrical diagrams" (the

cable has a cross-section and number of wires based on

the power and voltage of the machine).

Machine with EXTERNAL MOTOR PUMP

In case of external motor pump, proceed as follows:

1. Connect the motor pump cable (with smaller cross

section) to the connector of the external motor as

shown in the diagram below.

2. Connect the machine power cable (with larger

cross section) as set forth in the "Wiring diagrams"

chapter.

A

!

Always connect the motor pump cable before the

machine power supply cable, in accordance with

the diagram provided. Failure to comply with

the instructions given above may cause serious

damage to the machine and/or motor pump

and will invalidate the warranty. Carry out the

electrical connections only when the machine is

disconnected from the power supply.

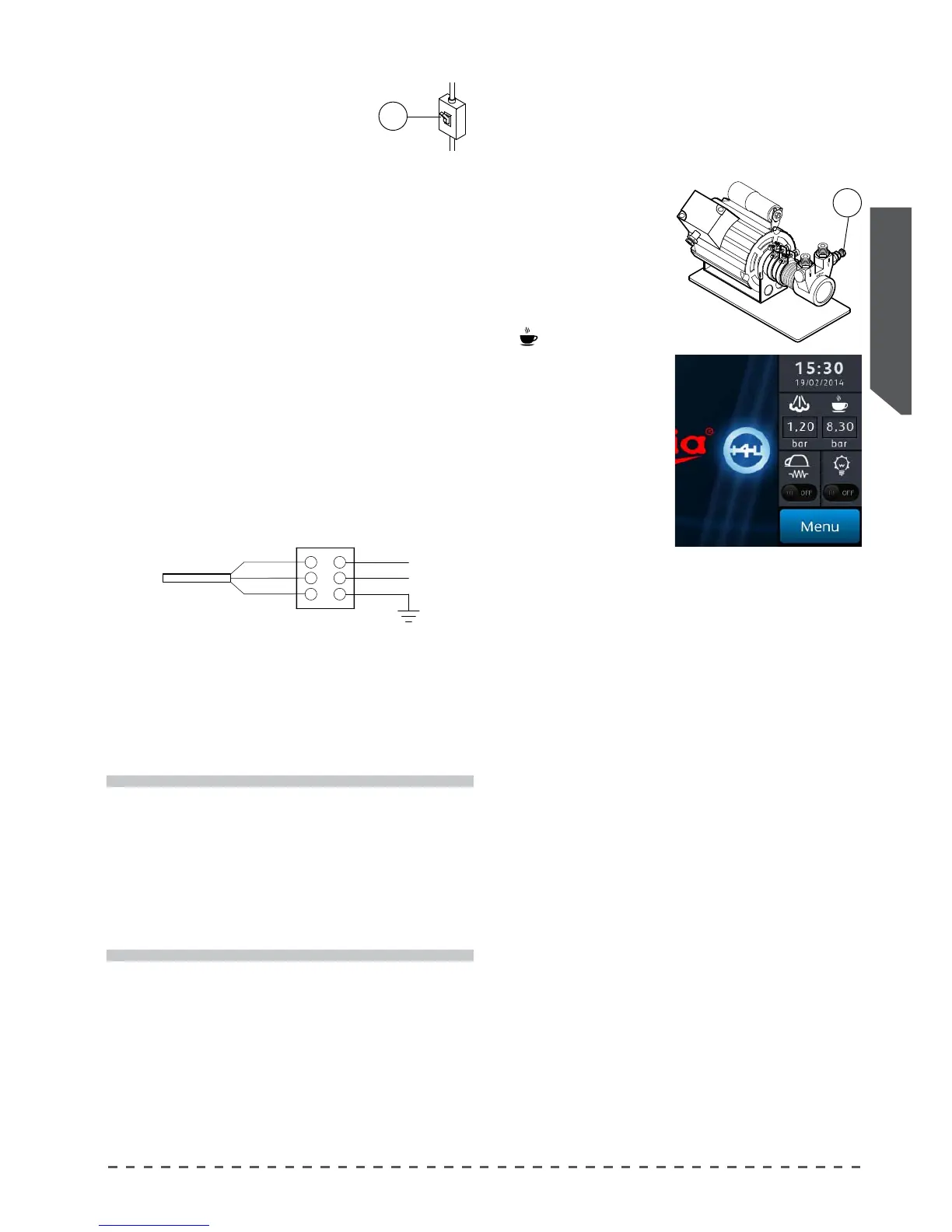

3.5 External motor pump adjustment

To adjust operating pressure proceed as follows:

• Operate a coee delivery switch;

• adjust the pressure by turning the screw located on

the pump (1) so as to

obtain a value between

8 and 9 bar: tightening

the screw increases

the pressure, and loos-

ening it reduces the

pressure. Check the

pressure on the display

(

) ;

• turn off the delivery

switch;

3.6 Machine tune-up

When installation is complete, the appliance has to be

started, brought to the nominal working condition and

left for 30 minutes in the "ready to operate" condition.

Afterwards, the appliance has to be turned o and

emptied of the first water introduced in the whole

hydraulic circuit, to eliminate possible initial impurities.

Then, the appliance must be once again loaded and

brought to the nominal working conditions.

After reaching the "ready to operate" condition, the

following has to be performed:

1. for each coee unit, carry out a continuous delivery,

in order to release the whole volume of water

contained in each associated coee tank;

2. release the entire volume of the hot water from the

boiler by continuous delivery through the specic

spout. In the case of several dispensing points,

divide the volume on the base of the number of

the dispensing points;

3. continuously release steam for at least 1 minute for

each steam dispensing point.

1

Loading...

Loading...