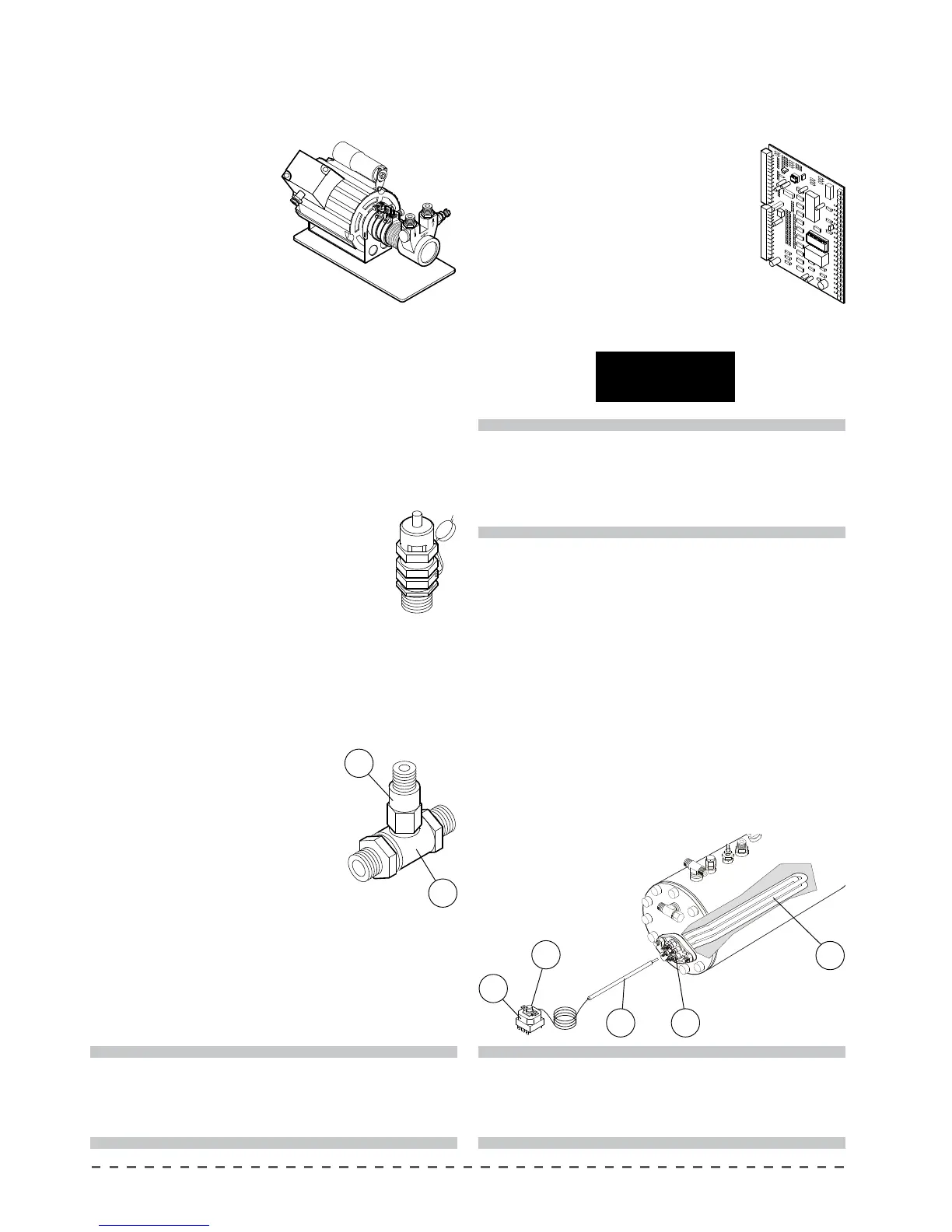

4.8 Pumping system

This is a component that feeds the machine, raising

the water pressure to 8-9

bar for coee delivery and

automatic filling of the

boiler.

4.9 Valve group

The valves are devices whose purpose is to ensure the

safety and proper operation of the machine.

4.9.1 Pressure limitation safety valve

The pressure relief valve guarantees that

the pressure in the boiler does not go above

2 bar. If there is a malfunction, the valve can

eliminate all the excess pressure from the

boiler.

4.9.2

Expansion - non-return valve

This is a valve consisting of an expansion valve and

a non-return valve.

• Expansion valve (1): the cold water sent from the

pump to the heat exchangers is heated. This heat-

ing causes an increase in the volume of water. To

limit pressure increases in the hy-

draulic circuit, the valve limits the

maximum internal pressure of the

circuit to 12 bar.

• non-return valve (2): Its function

is that of preventing the back ow

of water from the exchangers in

the hydraulic circuit.

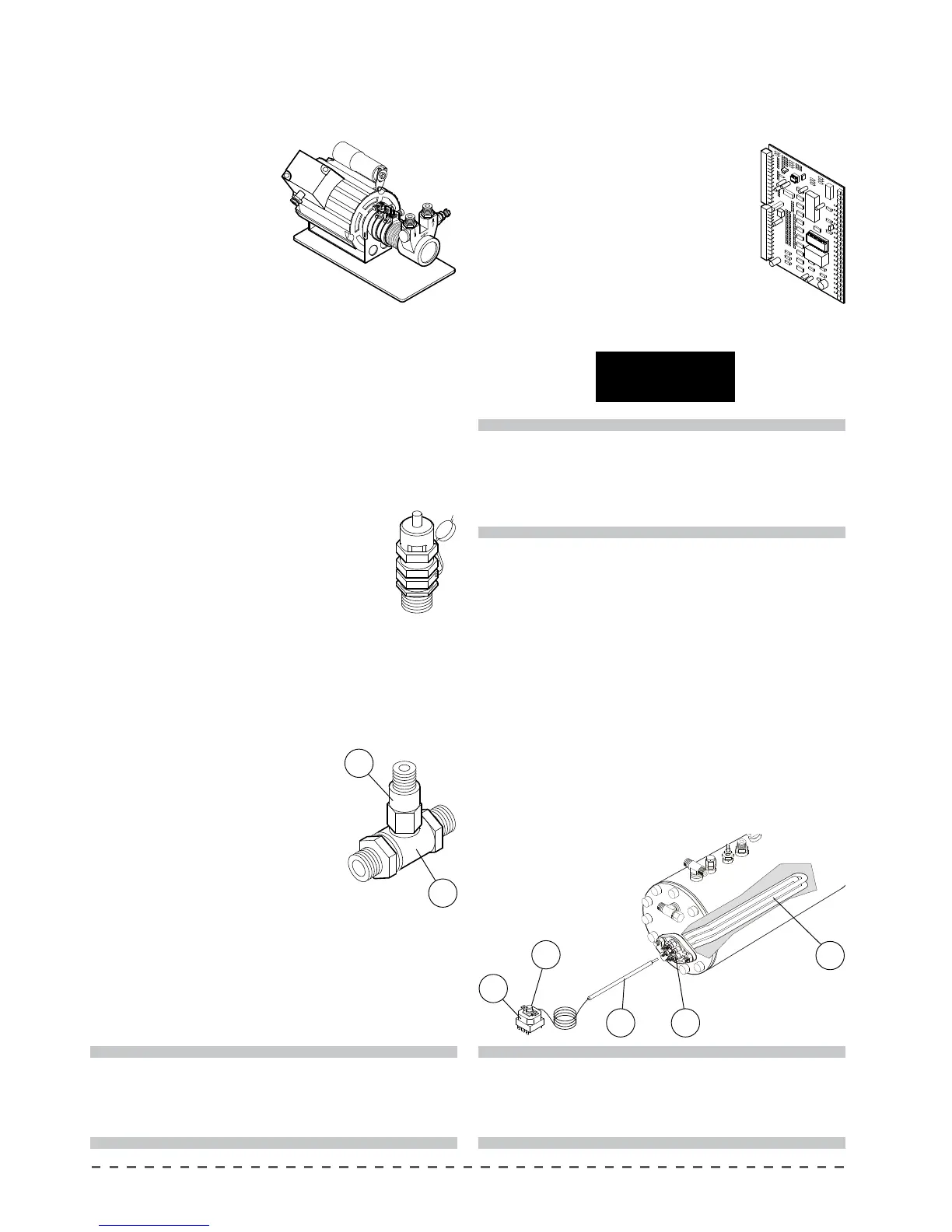

4.10 Electric control unit

The electronic control unit is the nerve center of the

machine. It monitors and controls all operation of the

unit.

The information related to the installed

software (date and version) can be seen on

the display when the machine is turned

on. the monitoring and control of the

entire functioning of the machine.

The information concerning the

installed software (date and version) can

be seen on the display when the machine

is turned on.

4.11 Thermostat

The thermostat allows you to avoid damage to the

electrical resistance in case of lack of water in the boiler.

The thermostat bulb (7) is located inside a sheath (8)

placed at the center of resistance. The contacts of the

thermostat (9) are connected to the electrical resistance

(10). If the electrical resistance is exposed due to

failure to load water to the boiler, the temperature of

the resistance increases dramatically. At this point, the

thermostat interrupts the power supply to the resistance

thus preventing damage.

1

2

DATA

REGISTER RESET

11

9

7 10

8

!

When the software is updated, as soon as the

machine is started the system loads the default

data. In this case you will need to set the machine

parameters again.

!

To reset the thermostat, press the center button

(11). However, before trying to operate the

machine, verify the causes of the blockade of the

water feeding the boiler.

!

The valves must be checked on a regular basis as

described in the chapter "Controls and maintenance".

Loading...

Loading...