3

4

2

1

17 Checks and maintenance

17.1 Check and maintenance operations

To ensure perfect safety and eciency of the machine

over time, it is necessary to carry out routine, preventive

and special maintenance. In particular, it is advisable

to carry out an overall check of the machine at least

once a year.

6

Intervention

Weekly

Monthly

Yearly

MACHINE

Carry out the cleaning as described in the previous

chapter.

X

FILTERS AND FILTER HOLDERS

Check the condition of the lters. Check for any

damage on the edge of the lters and check wheth-

er any coee grounds settle in the coee cup.

X

MACHINE

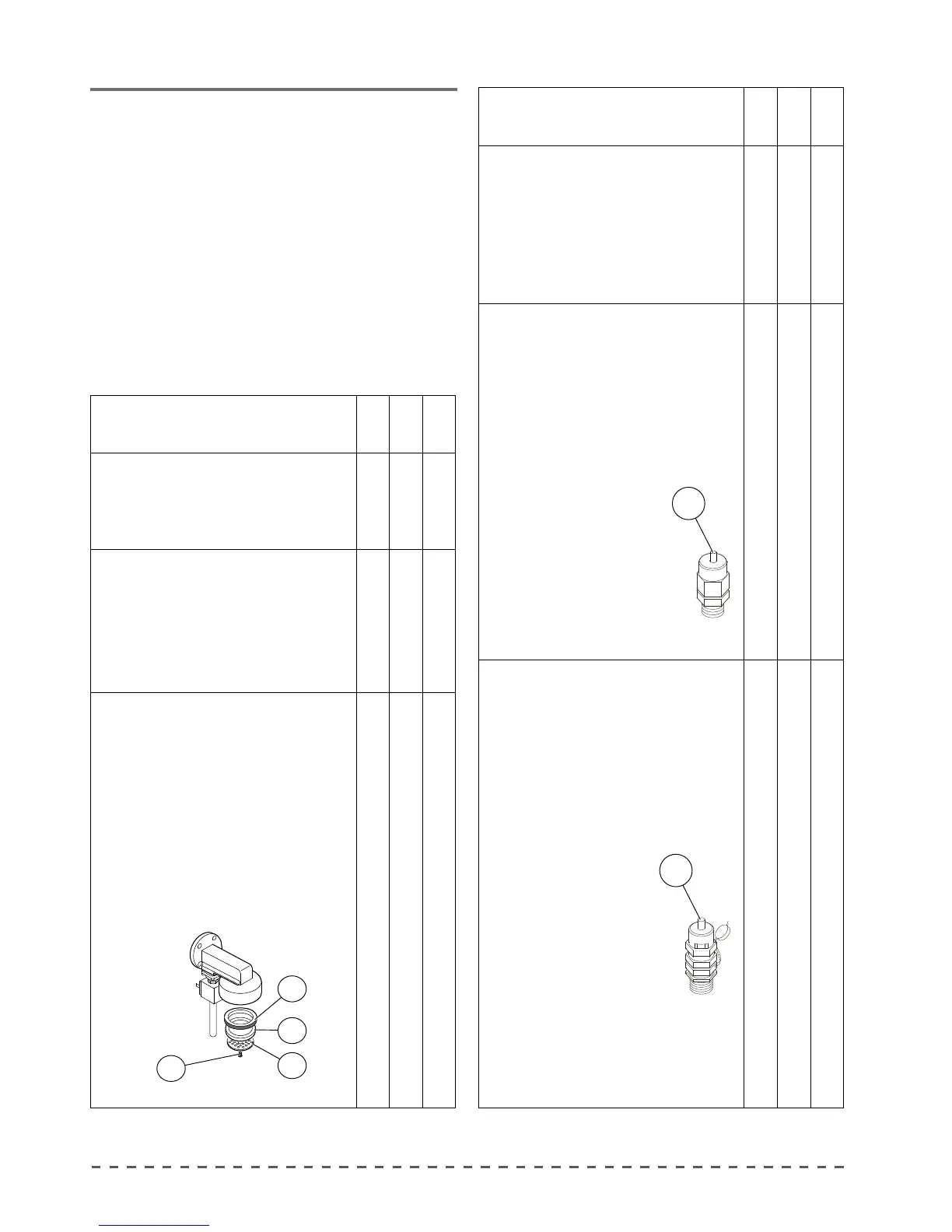

Every four months replace the perforated disk (2)

and the undercup seal (4) of the delivery group (use

only original spare parts) proceeding as follows:

1. loosen the screw (1);

2. remove the containment ring(3);

3. replace the group perforated disk (2) and the

rubber undercup seal (4);

4. reassemble the components

X

Intervention

Weekly

Monthly

Yearly

VALVES

Check for proper operation of the negative pres-

sure valve, pressure limiting valve and non-return

drain valve. If, owing to failure, their replacement

becomes necessary, repeat the test with the new

valve installed.

X

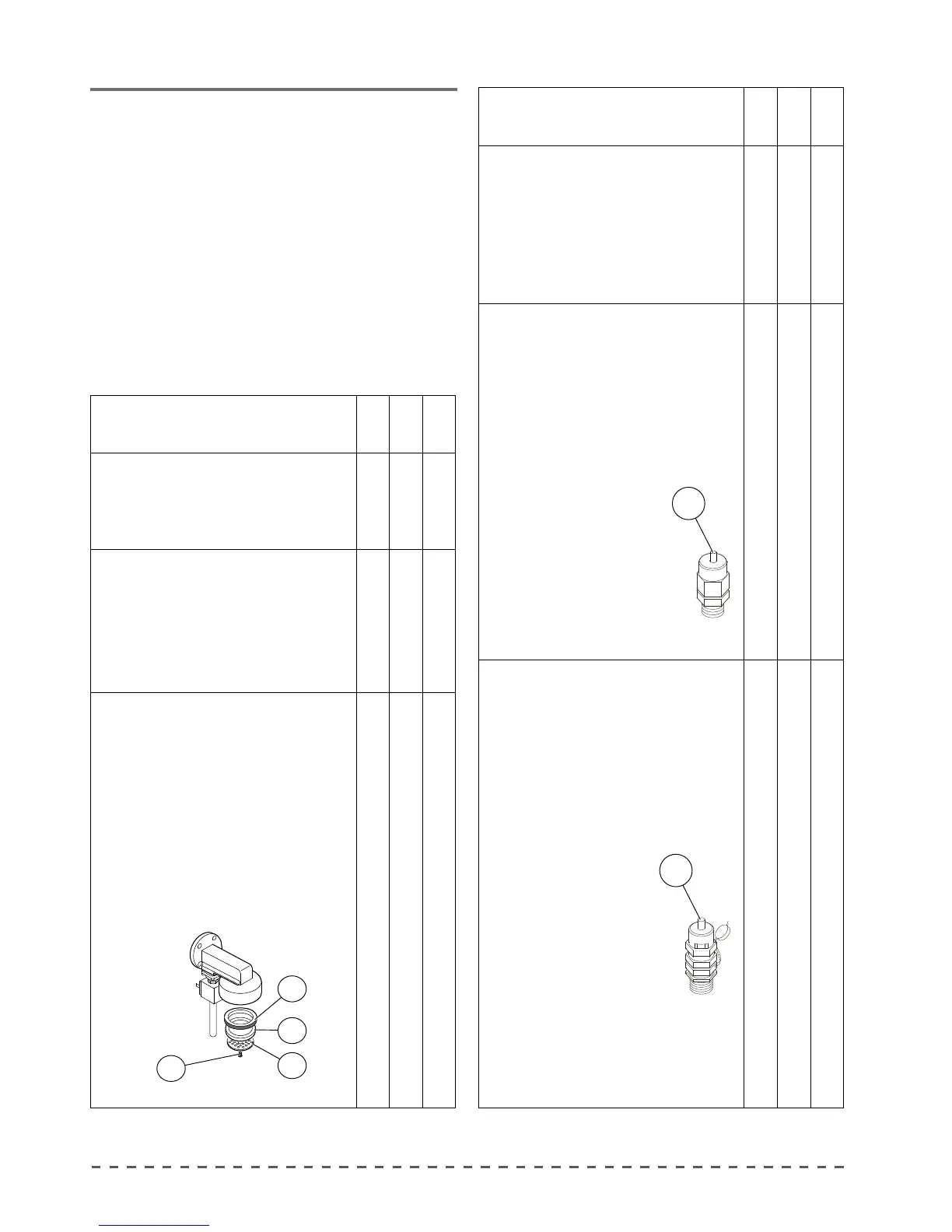

NEGATIVE PRESSURE VALVE

1) rst try :

• remove the top grill of the machine;

• use pliers to push the pin (5) downwards;

• if the pin does not move, it probably means the

valve is encrusted with limestone and must be

replaced.

2) second try :

• turn the machine o;

• open the steam valves and drain o

all the pressure from inside the boiler;

• turn the machine back on and check

for regular closure of the valve.

X

SAFETY OR PRESSURE RELIEF VALVE

1) rst try :

• remove the top grill of the machine;

• use pliers to pull the pin (6) upwards;

• if the pin does not move, it probably means the

valve is encrusted with limestone and must be

replaced.

2) second try :

• turn the machine o;

• block the pressure switch

contacts;

• turn the machine back on and

check for pressure in the boiler

to rise.

• check for correct intervention

of the valve at a maximum pressure of 2 bar.

X

5

Loading...

Loading...