Preamble

UM-22100H-U User manual ATEQ D520 Page 11/122

6. PRINCIPLE OF A CYCLE

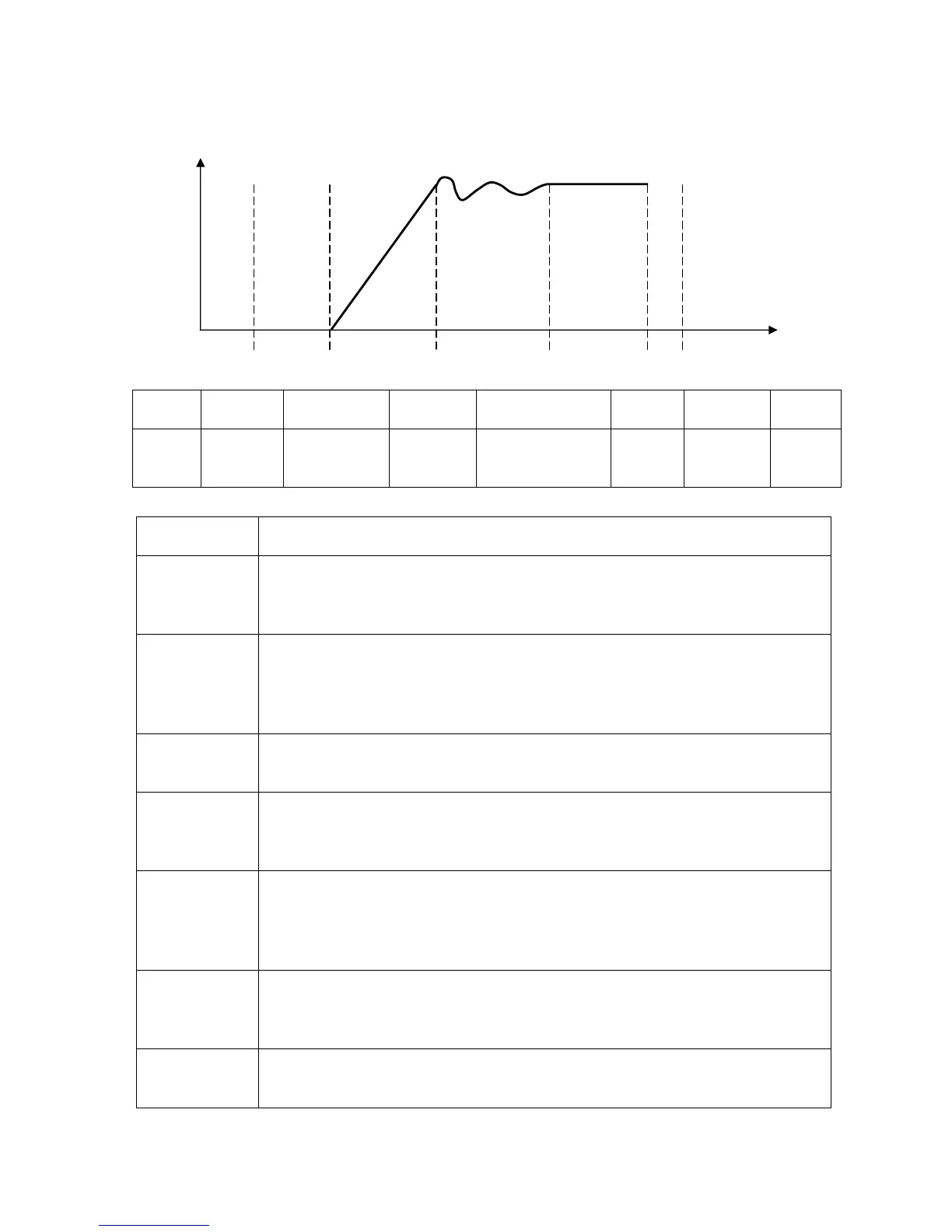

FILL STABILISATION TEST COUPLING

RESET*

RESET*

The measurement cycle is made of 4 phases:

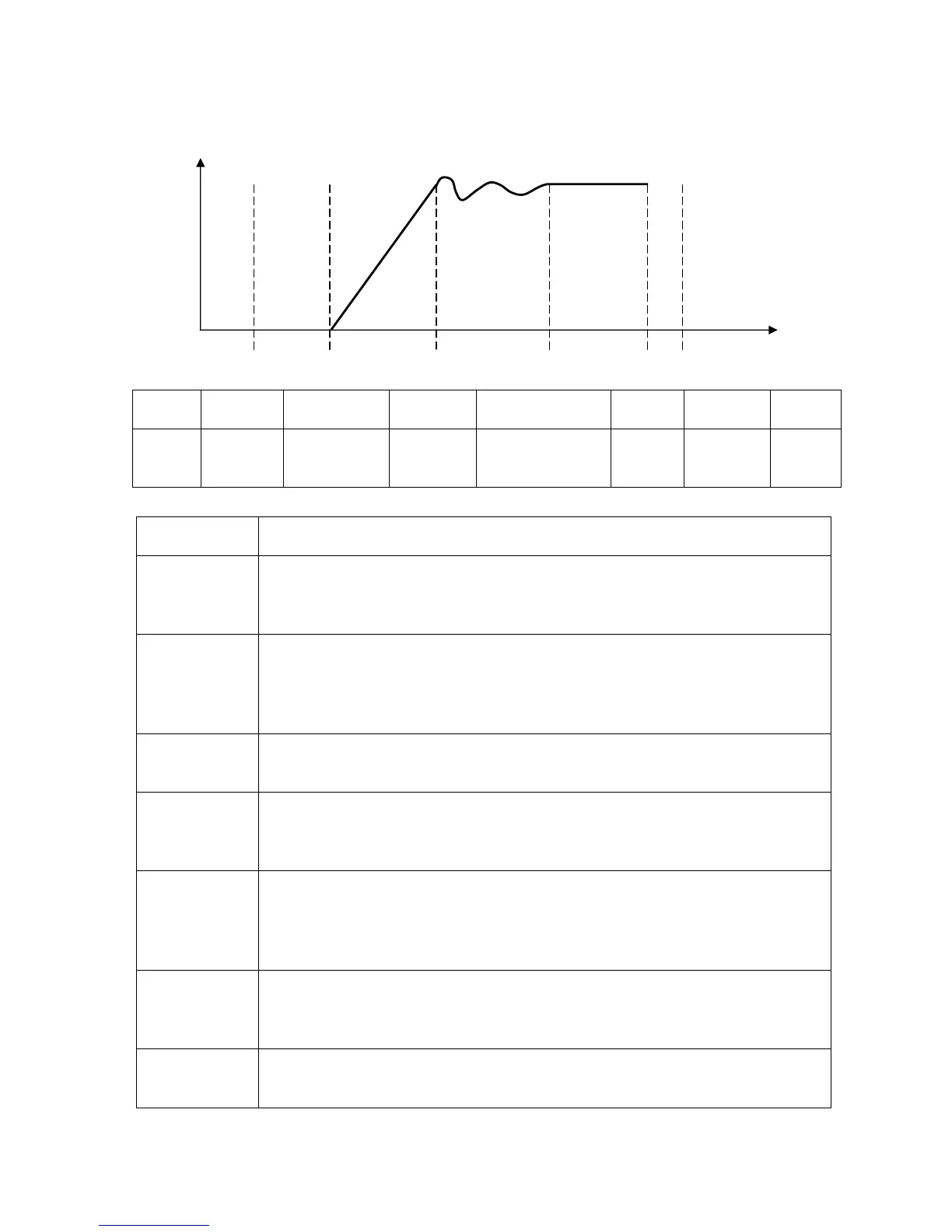

1 2 3 4 5 1'

Start

(Reset)* Coupling Fill Stabilisation Test (Reset)*

Cycle

end

Start

Start of the cycle.

(Reset)*

Reset of the pressure sensor to correct the eventual drifts, this phase

can be placed at the start or at the end of a cycle depending on the

requirement of the operator. Parameter to be set.

The

coupling

time

Time during which the sealing jig of the parts is put in place before the

part is filled. The instrument can be fitted with the automatic connector

option (this option adds a valve). This valve which is piloted throughout

the cycle time allows a control of the jig setup.

The fill time

This is the time during which the part is pressurised until the

compensation flow is obtained.

The

stabilisation

time

This is the time during which the flow value stabilises.

The test time

The differential pressure sensor measures the pressure difference on

the extremities of the calibrated flow tube. The signal is treated by the

electronics which display the result and indicate whether a part is good

or bad.

(Reset)*

Pressure sensor reset to correct eventual drifts. This phase can be

placed at the start of the cycle or at the end of the cycle depending on

the requirement of the operator. Parameter to be set.

End of

Cycle

The instrument stops the measurement and sends an end of cycle

signal.

Loading...

Loading...