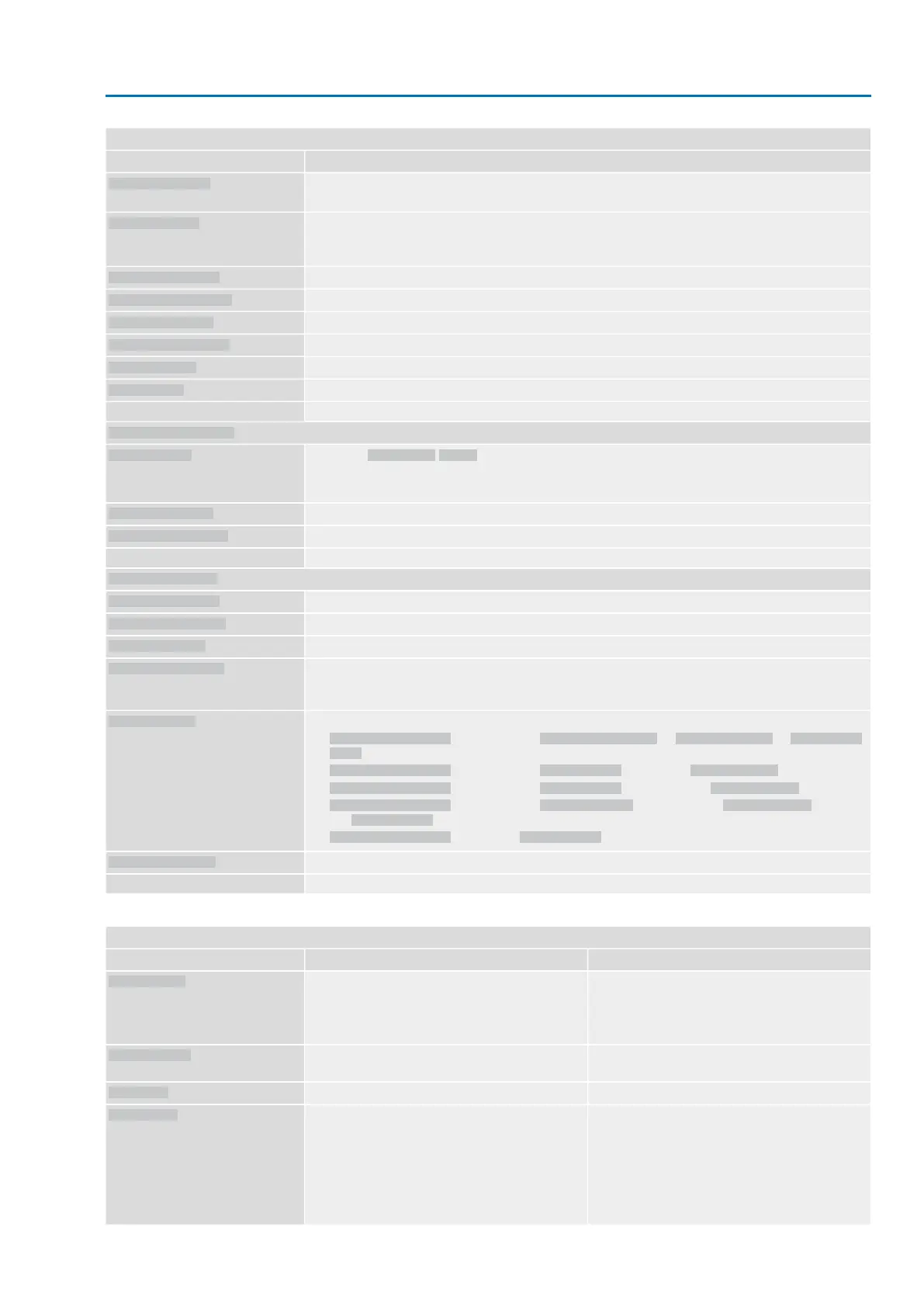

Individual indications

RemedyIndication on display

The 24 V DC customer auxiliary supply to control the digital inputs has failed.

Check 24 V DC inputs (DIN).

24 V DC customer

The internal 24 V DC power supply of the controls used to provide the electronics components (sub-

assemblies within the AC 01.2 controls and in the actuator) has exceeded the power supply limits .

Check internal 24 V DC voltage supply.

24 V DC internal

Reboot AUMATIC.

Wrn res. data in use

Operate actuator fully in end positions OPEN and CLOSED.

Wrn ref.actual position

Verify primary reduction gearing settings within the actuator.

Wrn range act.pos.

Check position feedback.

Wrn sign.loss act.pos.

Check system configuration.

Wrn event mark

Check system configuration.

Wrn Tm mark

Config. error REMOTE (Collective signal 22)

●

Check I/O interface M0139 parameter. The setting must correspond to the wiring diagram.

●

Check wiring.

●

Check I/O interface.

IE I/O interface

Check configuration.

IE remote interface

Check configuration.

IE remote Prm Config

FQM collective fault (Collective signal 25)

The result of the diagnostics via winding and blinker transmitter switch is available as fault.

FQM FS diag. result

Winding was not completed within the permissible initialisation time of 2.5 minutes.

FQM timeout winding

The end position switch was not active within the permissible waiting time of 10 seconds.

FQM timeout limit

The permissible tolerance range for the room temperature or the voltage range of the respective FQM

unit was fallen short of or exceeded or the permissible tolerance range for 24 V DC at ESD input was

fallen short of or exceeded for a period of minimum 1 second.

FQM fault temp.-volt.

The signal is generated if one of the following conditions applies:

●

FQM FS-ESD request not active AND FQM timeout winding or FQM timeout limit or FQM timeout

motor active

●

FQM FS-ESD request not active AND FQM FS ready active AND FQM FS-PosOk not active

●

FQM FS-ESD request not active AND FQM FS ready not active AND FQM FS-PosOk active

●

FQM FS-ESD request not active AND FQM fail safe ini. executed AND (FQM FS-PosOk not active

OR FQM FS ready not active)

●

FQM FS-ESD request active AND FQM FS ready active

FQM fail safe flt

The electric motor does not rotate during an initialisation operation.

FQM timeout motor

Table 27:

Status texts in menu S0001

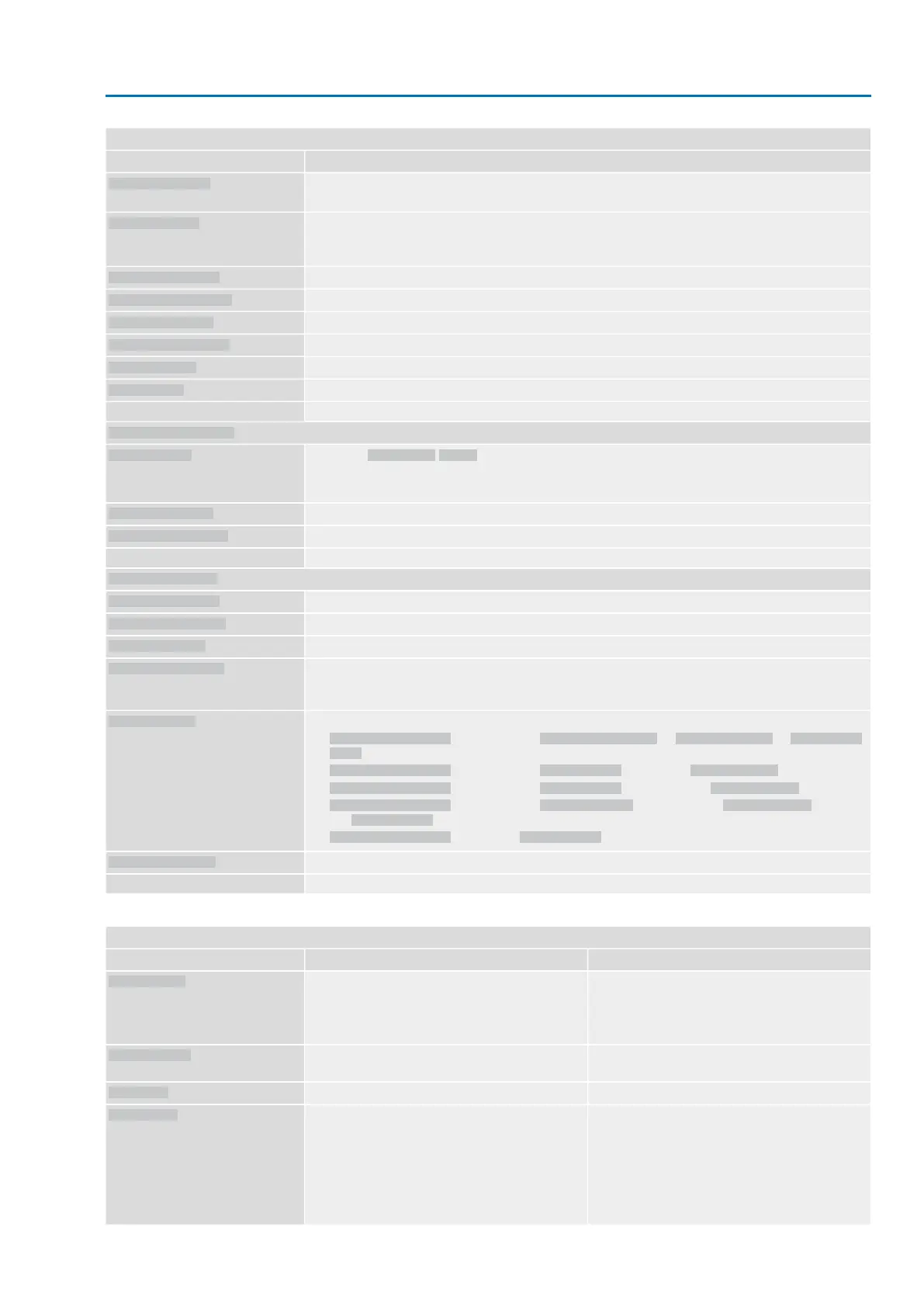

RemedyDescription/causeIndication on display

Check or replace hardware.Hardware is either defective or not available:

●

for potentiometer, RWG, EWG = signal loss

●

for MWG = calibration active or Hall sensor de-

fective

Sensor failure

Set end positions and perform reference operation.For potentiometer, RWG, EWG: end positions not

set

Not referenced

Calibration active

Calibration

Set valid stroke.Outside the value range

●

for potentiometer = insufficient stroke between

the set end positions

●

for RWG, EWG = end position OPEN = end

position CLOSED

●

for MWG = excessive stroke between the set

end positions

Out of range

141

Actuator controls

AC 01.2/ACExC 01.2 Profinet Corrective action

Loading...

Loading...