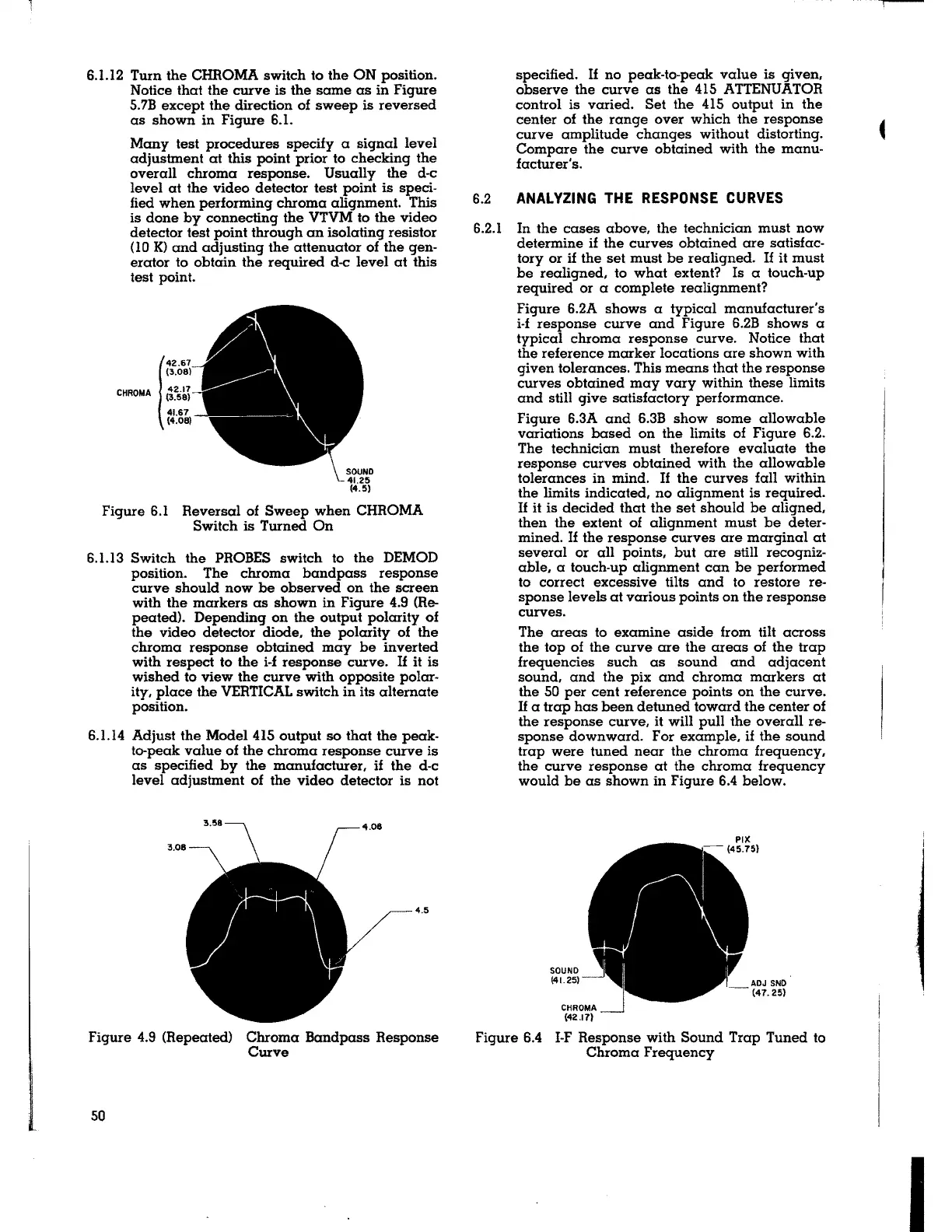

6.1.12 Turn the CHROMA switch to the ON position.

Notice that the curve is the same as in Figure

5.7B except the direction of sweep is reversed

as shown in Figure 6.1.

Many test procedures specify a signal level

adjustment at this point prior to checking the

overall chroma response. Usually the d-c

level at the video detector test point is speci-

fied when performing chroma alignment. This

is done by connecting the VTVM to the video

detector test point through an isolating resistor

(10 K) and adjusting the attenuator of the gen-

erator to obtain the required d-c level at this

test point.

(

42.67

(3.08)

CHROMA

42

.1

7

(3.58)

41.67

(4.08)

Figure 6.1 Reversal of Sweep when CHROMA

Switch is Turned On

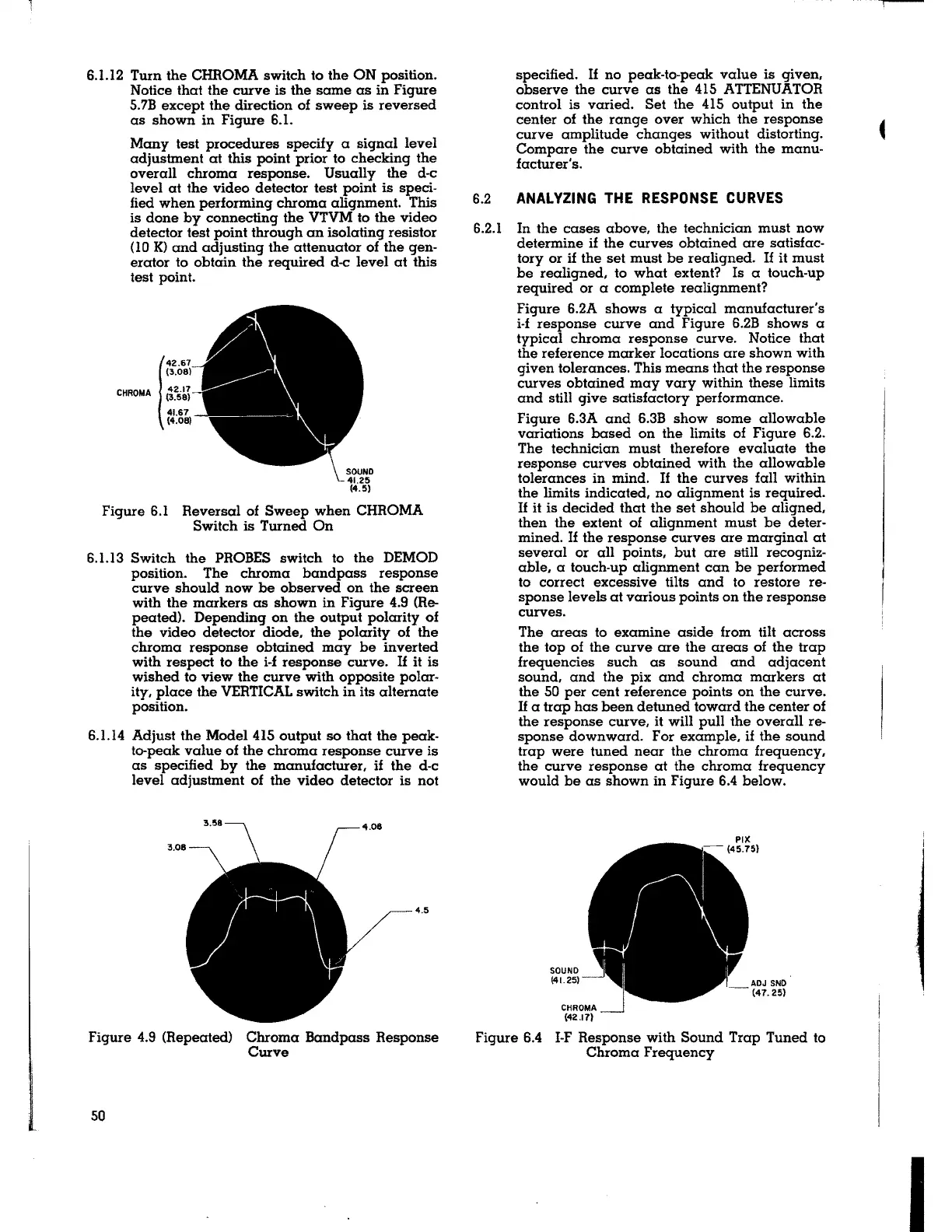

6.l.13 Switch the PROBES switch to the DEMOD

position. The chroma bandpass response

curve should now be observed on the screen

with the markers as shown in Figure 4.9 (Re-

peated). Depending on the output polarity of

the video detector diode, the polarity of the

chroma response obtained may be inverted

with respect to the i-f response curve.

If it is

wished to view the curve with opposite polar-

ity, place the VERTICAL switch in its alternate

position.

6.1.14 Adjust the Model 415 output so that the peak-

to-peak value of the chroma response curve is

as specified by the manufacturer, if the d-c

level adjustment of the video detector is not

3.58

4.08

4.5

Figure 4.9 (Repeated) Chroma Bandpass Response

Curve

50

specified. If no peak-to-peak value is given,

observe the curve as the 415 ATTENUATOR

control is varied. Set the 415 output in the

center of the range over which the response

curve amplitude changes without distorting.

Compare the curve obtained with the manu-

facturer's.

6.2

ANALYZING THE RESPONSE CURVES

6.2.l In the cases above, the technician must now

determine if the curves obtained are satisfac-

tory or if the set must be realigned. If it must

be realigned, to what extent? Is a touch-up

required or a complete realignment?

Figure 6.2A shows a typical manufacturer's

i-f response curve and Figure 6.2B shows a

typical chroma response curve. Notice that

the reference marker locations are shown with

given tolerances. This means that the response

curves obtained may vary within these limits

and still give satisfactory performance.

Figure 6.3A and 6.3B show some allowable

variations based on the limits of Figure

6.2.

The technician must therefore evaluate the

response curves obtained with the allowable

tolerances in mind.

If the curves fall within

the limits indicated, no alignment is required.

If it is decided that the set should be aligned,

then the extent of alignment must be deter-

mined. If the response curves are marginal at

several or all points, but are still recogniz-

able, a touch-up alignment can be performed

to correct excessive tilts and to restore re-

sponse levels at various points on the response

curves.

The areas to examine aside from tilt across

the top of the curve are the areas of the trap

frequencies such as sound and adjacent

sound, and the pix and chroma markers at

the 50 per cent reference points on the curve.

If a trap has been detuned toward the center of

the response curve, it will pull the overall

re-

sponse downward. For example, if the sound

trap were tuned near the chroma frequency,

the curve response at the chroma frequency

would be as shown in Figure 6.4 below.

SOUND

(41.25)

ADJ SND

(47.25)

Figure 6.4 I-F Response with Sound Trap Tuned to

Chroma Frequency

I

Loading...

Loading...