59

925.916.2 - GBINSTRUCTIONS PERTAINING TO THE INSTALLER

IMPORTANT: in the case of conversion from natural gas to propane (LPG), the following operations must be performed

before calibrating the gas valve as illustrated above:

• Turn adjuster screw (V) on the gas valve through the number of complete revolutions specied in table 3 or 3.1;

• On the control panel display set ignition power parameters H608 and H611. The values to be input are given in table 3

or 3.1. The programming methods are described in chapter 17;

To simplify calibration of the gas valve, the “calibration function” can be set directly on the boiler control panel by pro-

ceeding as follows:

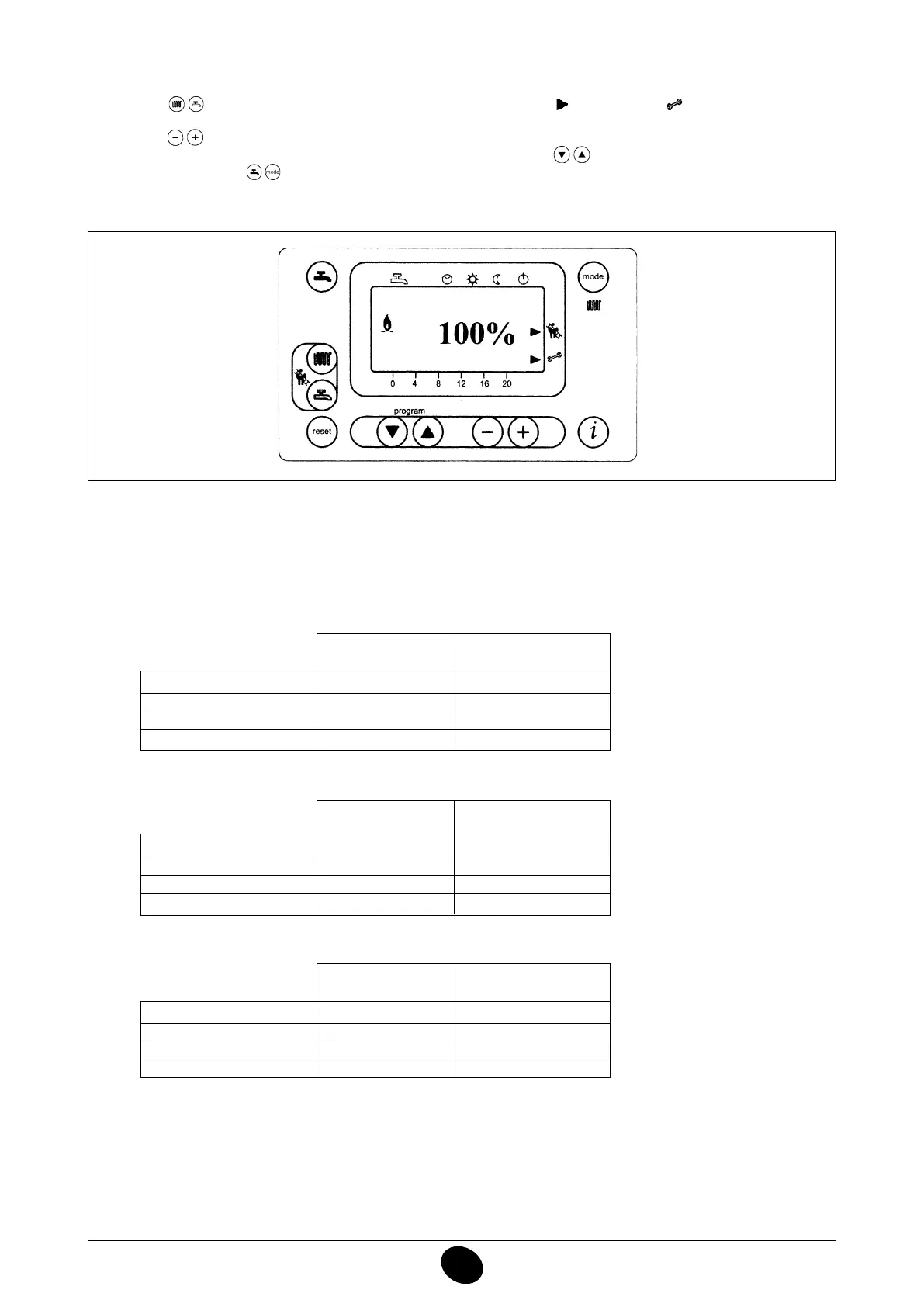

1) Press the keys (2-3) together until the display shows the pointer “ ” alongside the symbol (about 6 secon-

ds).

2) Press the

keys to set the fan speed at the minimum and maximum heat output (%PWM);

N.b - to set the

minimum and maximum heat output quickly, press the keys respectively;

3) press either of the two keys to exit the function..

0307_2201

Figure 15

LUNA3 SYSTEM HT 1.240 MP

G20 - 2H - 20 mbar G31 - 3P - 37 mbar

CO

2

max. heat output 8,7% 10%

CO

2

min. heat output 8,4% 9,5%

CO max

< 250 ppm < 250 ppm

Gas nozzle 7,5 mm 7,5 mm

LUNA3 SYSTEM HT 1.180 MP

G20 - 2H - 20 mbar G31 - 3P - 37 mbar

CO

2

max. heat output 8,7% 10%

CO

2

min. heat output 8,4% 9,5%

CO max

< 250 ppm < 250 ppm

Gas nozzle 5,7 mm 5,7 mm

Table 1c

Table 1b

LUNA3 SYSTEM HT 1.330 MP

G20 - 2H - 20 mbar G31 - 3P - 37 mbar

CO

2

max. heat output 8,7% 10%

CO

2

min. heat output 8,4% 9,8%

CO max

< 250 ppm < 250 ppm

Gas nozzle 12,0 mm 12,0 mm

Table 1a

Loading...

Loading...