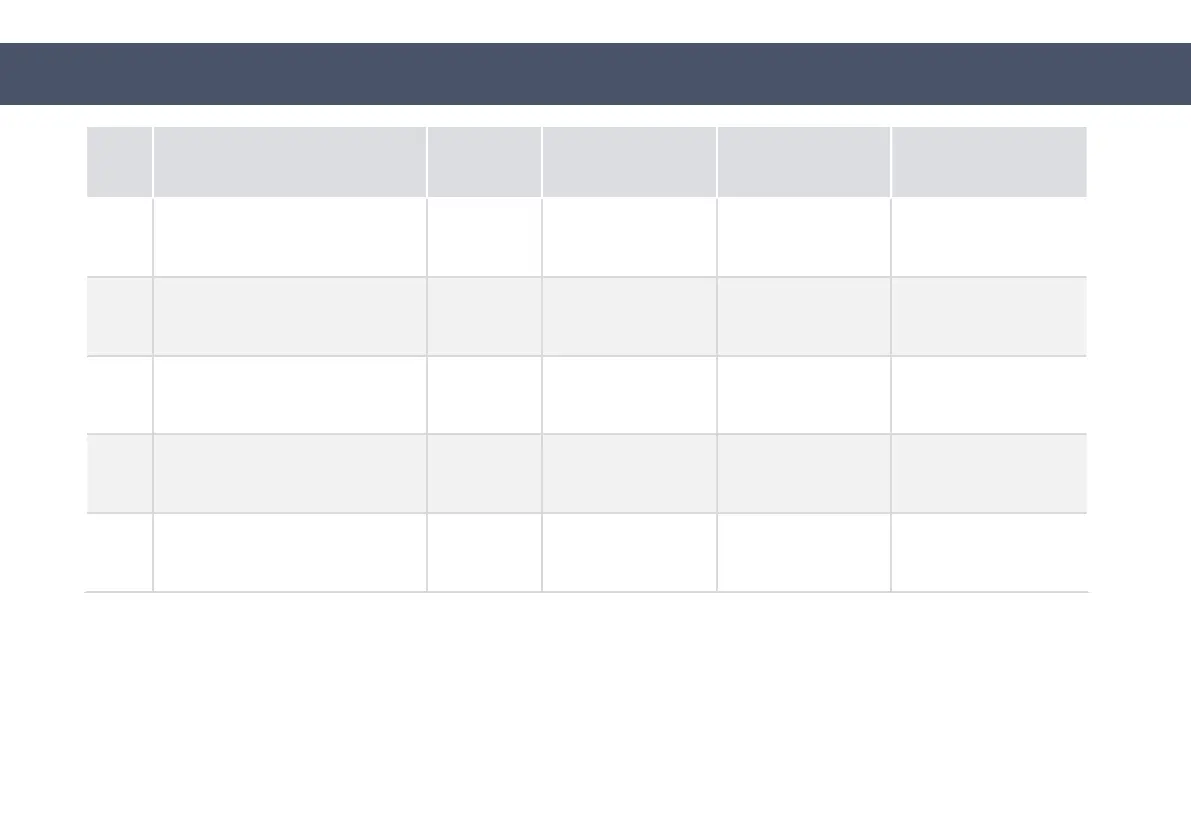

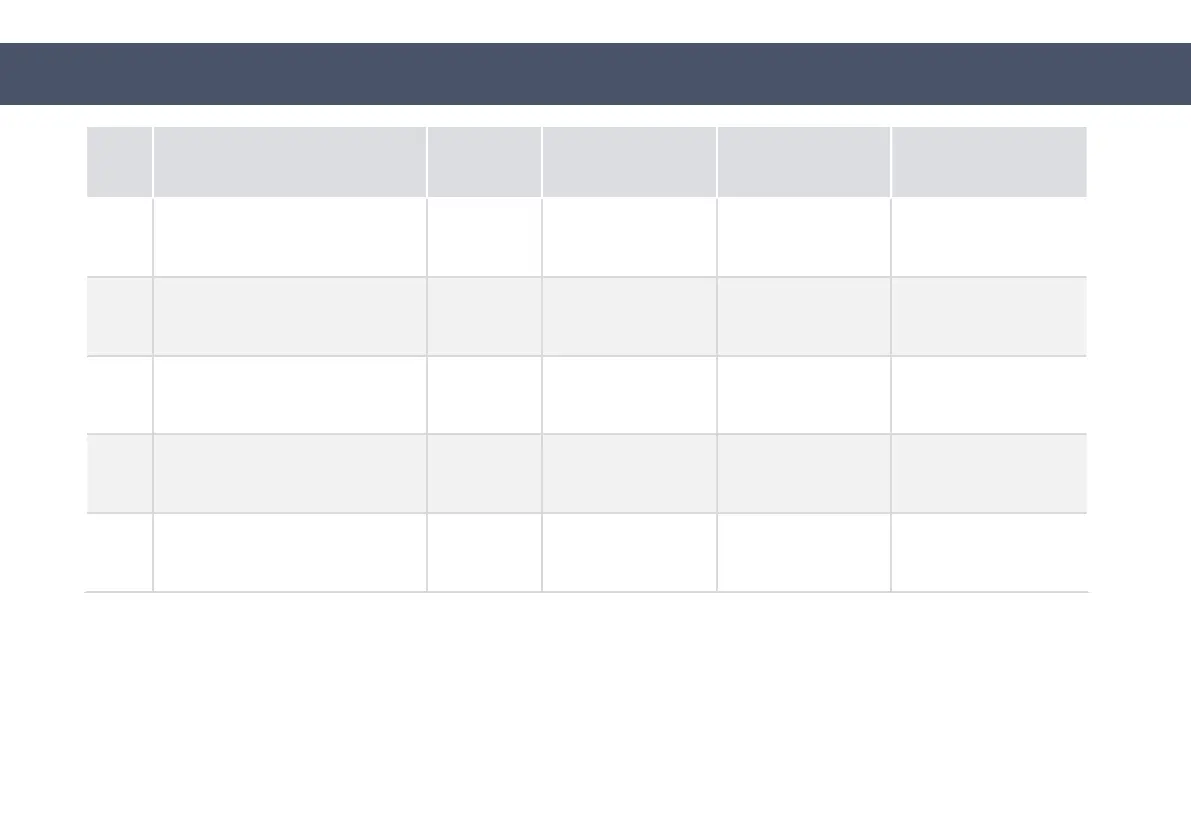

Pos. Number - maintenance

point

Interval Lubricant speci‐

fication

Lubricant quan‐

tity

Remark

1 Top hydraulic cylinder for

trough

daily KP2K-30

DIN 51825

until grease

emerges

2 lubrication nip‐

ples

2 Locating bolts for

trough

daily KP2K-30

DIN 51825

until grease

emerges

2 lubrication nip‐

ples

3

Swivel equipment

hydraulic

cylinder

daily KP2K-30

DIN 51825

until grease

emerges

4 lubrication nip‐

ples

4 Swing bearing daily KP2K-30

DIN 51825

until grease

emerges

5 lubrication points

5 Lower hydraulic cylinder for

trough

daily KP2K-30

DIN 51825

until grease

emerges

2 lubrication nip‐

ples

Tab. 9.5: Round tipping trough lubrication points

50-020-1011-900_EN

1.0 - © 2/15/2017

247

9 Daily maintenance work

9.3 Maintenance work to be carried out

Loading...

Loading...