Section 03 ENGINES

Subsection 05 (TOP END)

A02C2MA

Using square end of tool, push circlip in until it

rests in groove.

A02C2NA

1

1. Circlip in groove

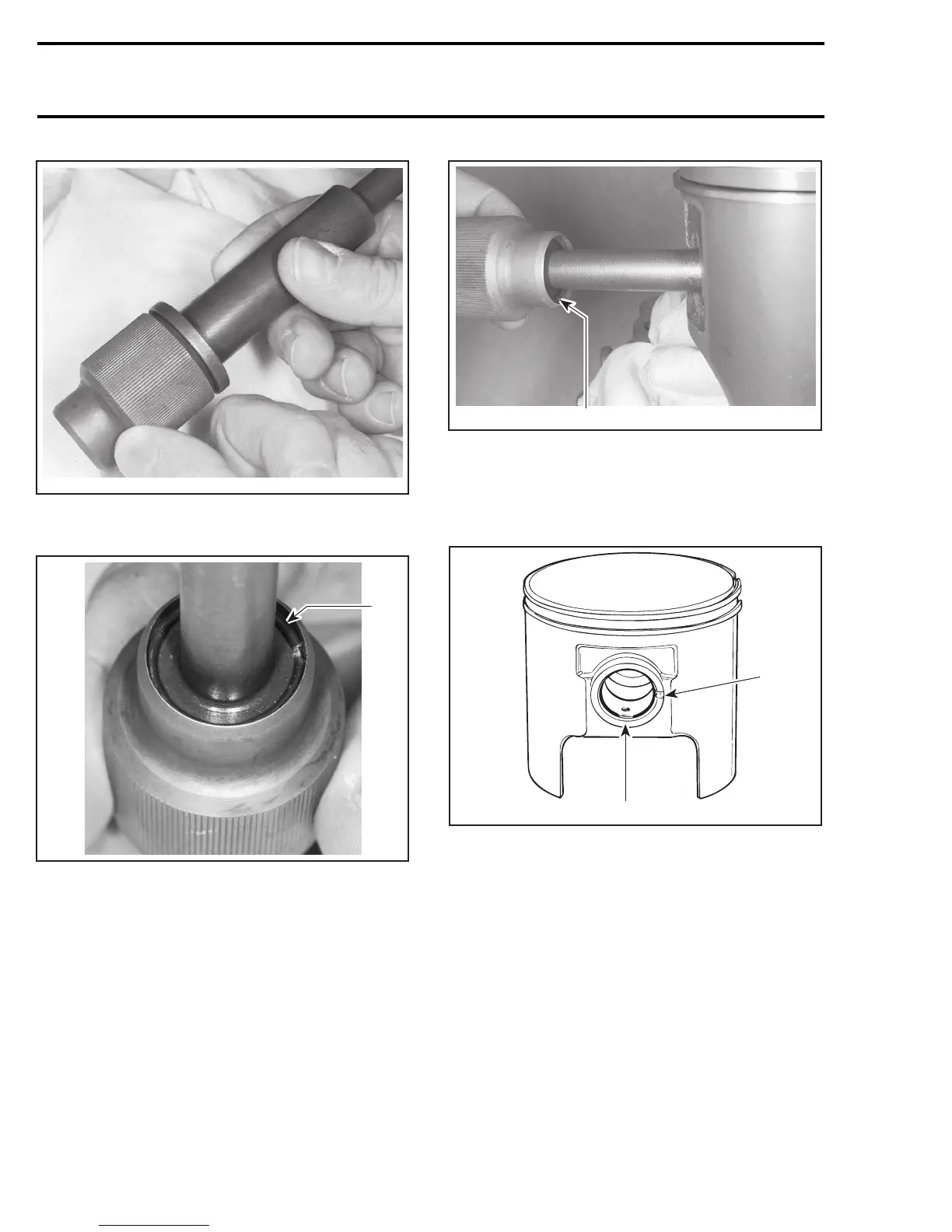

Mount tool in piston making sure that circlip break

is facing down.

1

A02C2OA

TYPICAL

1. Circlip break facing down

Hold tool firmly against piston then strike on round

end of tool with a plastic hammer. Circlip will

movefromtoolgroovetopistongroove.

1

2

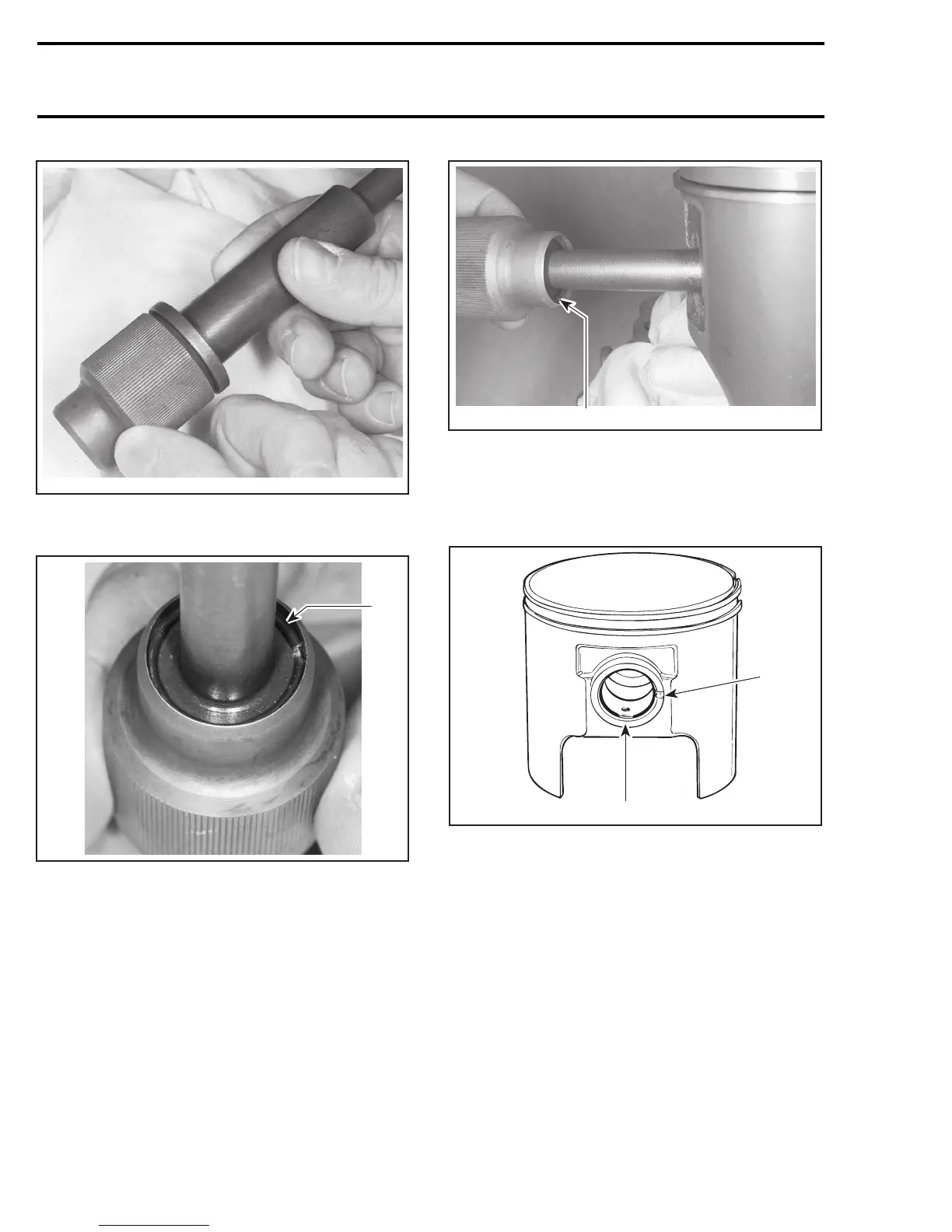

A01C02A

1. Piston notch

2. Circlip break at 6 o’clock

CAUTION: Circlips must not move freely in the

groove after installation. If so, replace them.

552 Engine

When reinstalling original needle bearings, make

sure that 34 needles are inserted between sleeve

and locating sleeve.

When installing a new cageless bearing, replace

half plastic cages by sleeve.

88 mmr2005-072

Loading...

Loading...