Section 08 DRIVE SYSTEM

Subsection 03 (DRIVEN PULLEY)

A03D2SA

1

2

2

2

1

1

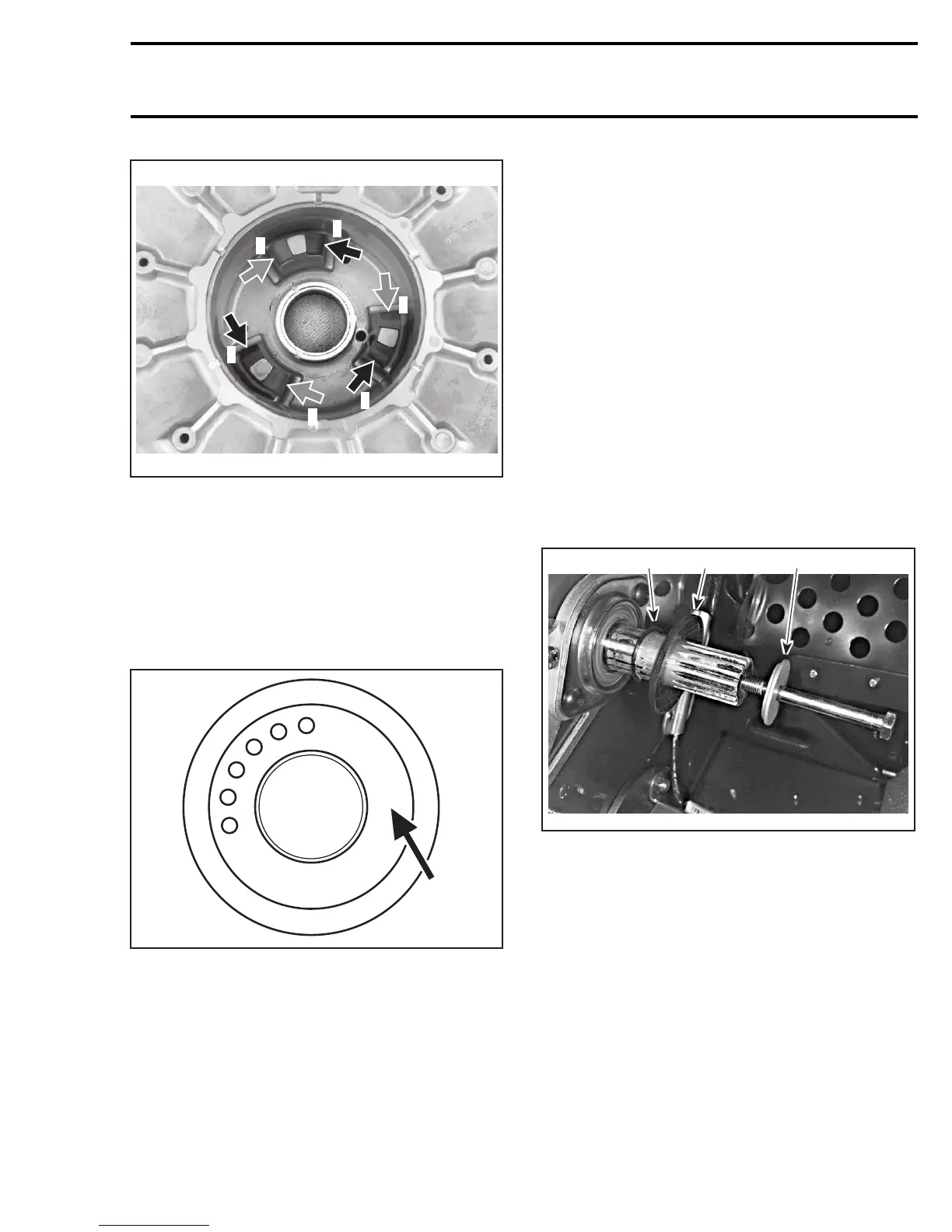

1. BLACK slider shoe

2. RED slider shoe

Assemble driven pulley components by reversing

the disassembly procedure.

Cam and Spring

Make sure to install proper cam. Refer to TECH-

NICAL DATA.

Cam angle is identified on cam.

B

O

M

B

A

R

D

I

E

R

6

5

4

3

2

1

44°

A24D06A

Install spring no. 6 in sliding half with its end in-

serted in hole B.

Position cam no. 5 then insert spring in adjusting

hole no. 2 into outer cam.

IMPORTANT: With the spring ends at positions

B and 2, spring preload is equal to zero (0). To

work properly, the driven pulley must have a zero

preload.

Compress outer cam using the clutch spring com-

pressor (P/N 529 035 524). Install washer no. 4

then secure outer cam with circlip no. 3.

CAUTION: Ensure that circlip is properly insert-

ed into shaft groove and that spacer recess is

facing circlip.

INSTALLATION

Countershaft

Apply Loctite antiseize lubricant (P/N 293 800 070)

on countershaft splines.

CAUTION: Always apply antiseize on the coun-

tershaft before final pulley installation to pre-

vent a possible seizing up between pulley and

countershaft.

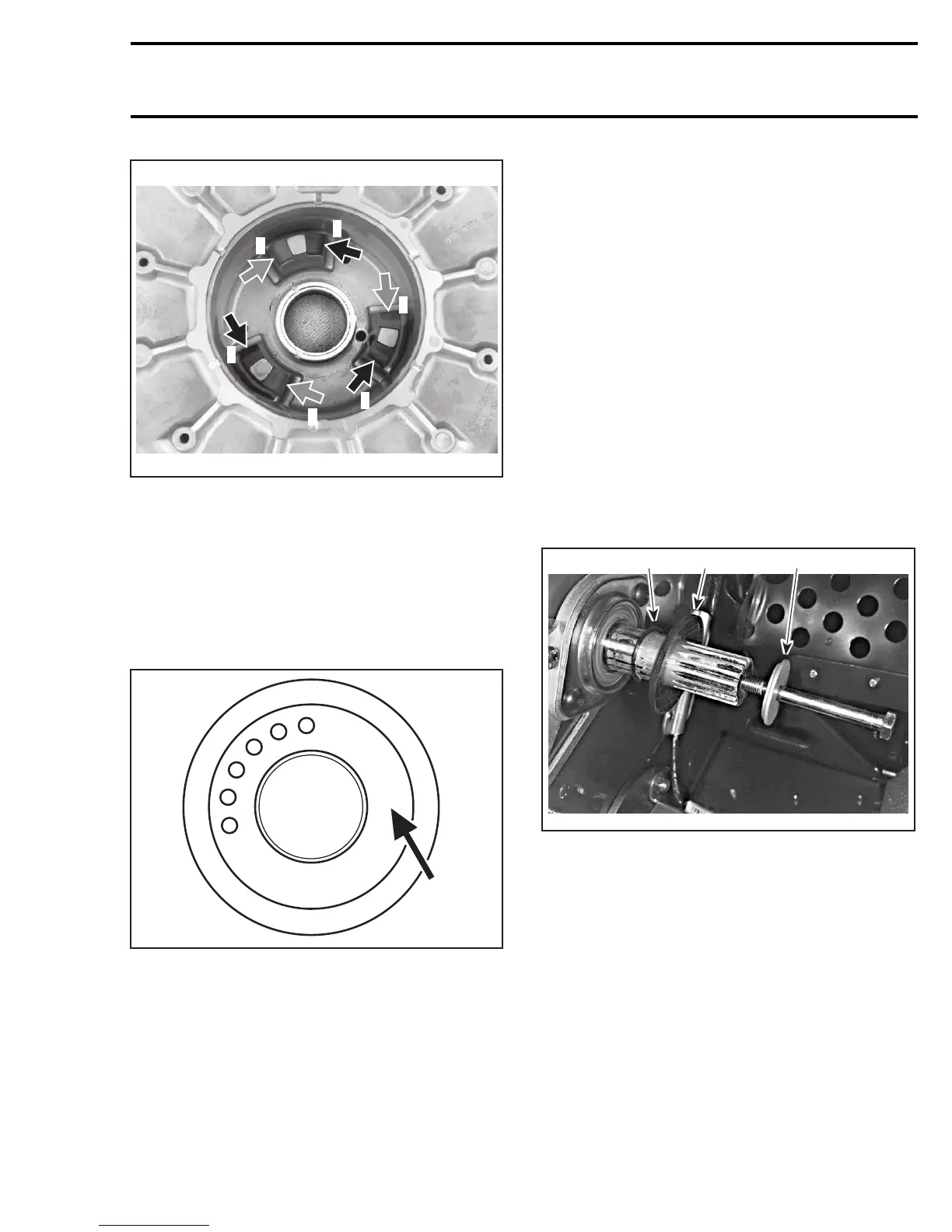

Make sure that spacer no. 2 is on countershaft

no. 1 before installing driven pulley. Note also that

washer shoulder is facing driven pulley.

A30D14A

1 23

TYPICAL

1. Spacer

2. Shoulder on this side

3. Concavesidefacingdrivenpulley

Should installation procedure be required, refer to

BRAKE then look for BRAKE DISC and COUNTER-

SHAFT BEARING ADJUSTMENT.

Reinstall the pulley on the countershaft by revers-

ing the removal procedure.

Pulley Retaining Screw

Torque pulley retaining screw no. 14 to 25 N•m

(18 lbf•ft).

mmr2005-088 343

Loading...

Loading...