Section 06 ENGINE MANAGEMENT (SDI)

Subsection 03 (COMPONENT INSPECTION, REPLACEMENT AND ADJUSTMENT)

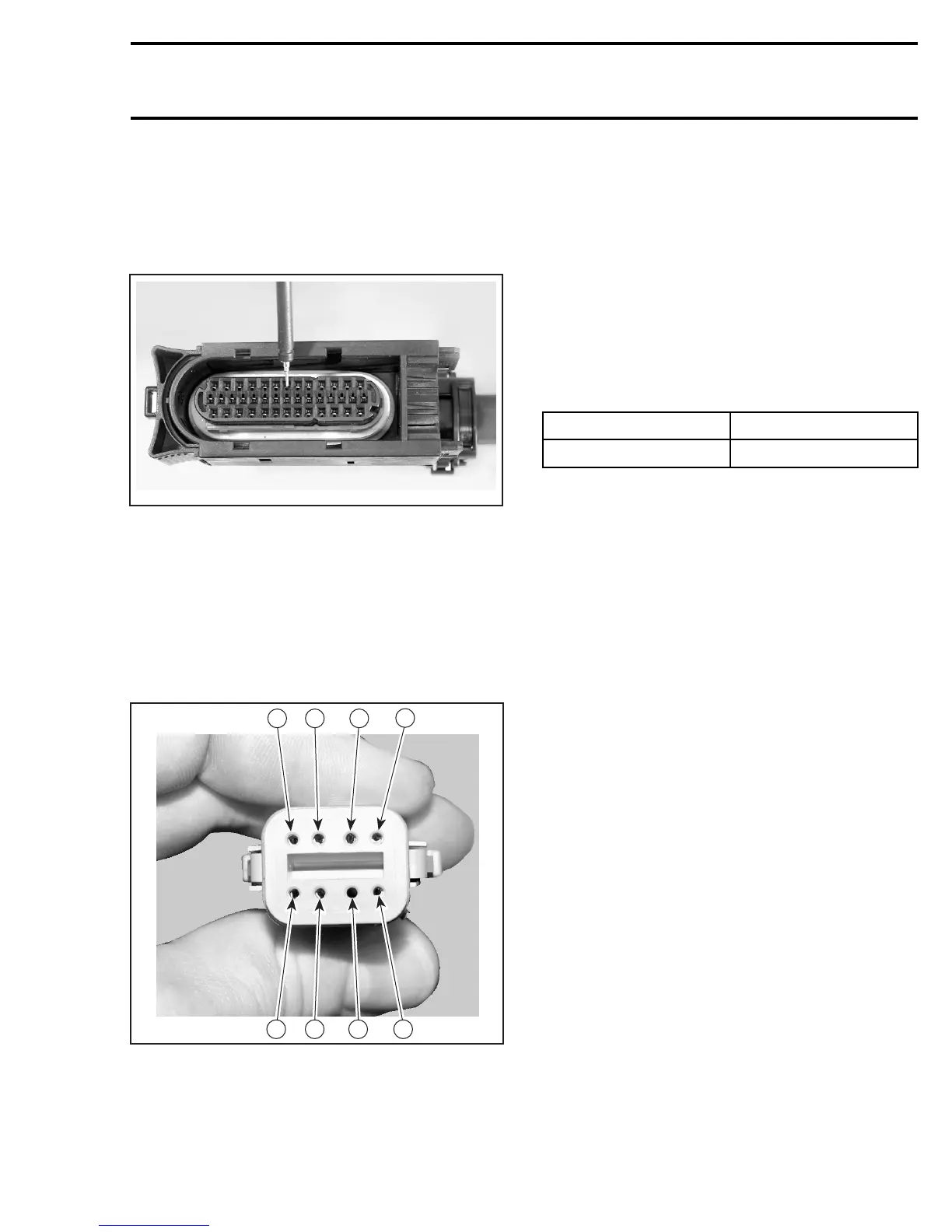

CAUTION: Probe on top of terminal only. Do

not try to probe inside terminal or to use a pa-

per clip to probe inside terminal, it will dam-

age the square-shaped terminal and this could

lead to improper function of the engine man-

agement system.

A32CCPA

PROBE ONLY ON THE PIN NOZZLE OF FEMALE CONNECTOR

CAUTION: Do not disconnect the ECM connec-

tor needlessly. They are not designed to be dis-

connected/reconnected repeatedly.

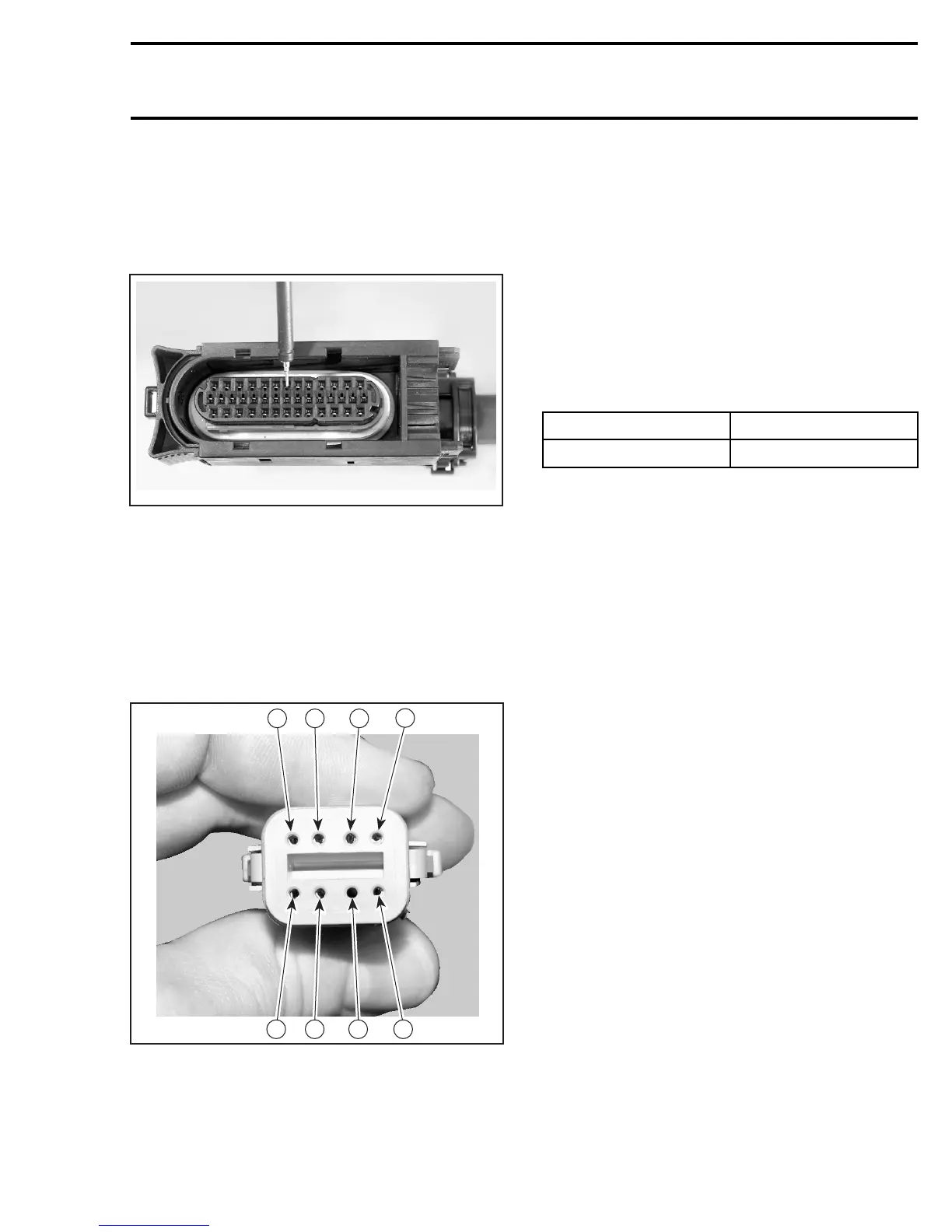

Engine Connector

Use this illustration to locate the pin numbers on

the engine connector of the wiring harness when

performing tests.

6

A32C9IA

7

8

5

1

2

34

ENGINE CONNECTOR PIN-OUT (WIRING HARNESS SIDE)

RELAY

Relay 2

Connect vehicle communication kit (VCK) and use

B.U.D.S. software.

Energize relay 2 from Activation tab.

Listen to or touch relay to feel it click.

If the relay does not work, disconnect the connec-

tor from the relay to test the input side.

Connect a voltmeter as indicated in the following

table.

TEST PROBE (+) TEST PROBE (-)

RED/GRAY wire

Battery ground

Battery voltage (12 V) should be read.

If voltage reads 12 V, check continuity of OR-

ANGE/GREEN wire between relay connector

and pin B-16 of ECM connector. If faulty, repair

wire/connector. If wire/connectors test good, try

anewECM.

If voltage does not read 12 V, check continuity

of wire on supply side of relay. If faulty, repair

wire/connector. If wire/connectors test good, re-

fer to ELECTRICAL SYSTEM to test output side or

relay.

mmr2005-081 253

Loading...

Loading...