Section 08 DRIVE SYSTEM

Subsection 01 (DRIVE BELT)

DRIVEBELTDEFLECTION

MEASUREMENT (REFERENCE

ONLY)

NOTE: The drive belt deflection measurement

must be performed each time a new drive belt is

installed.

NOTE: To obtain an accurate drive belt deflection

measurement, it is suggested to allow a break-in

period of 50 km (30 miles).

Before checking the belt deflection, ensure vehi-

clehastheproperbelt(refertotheAPPLICATION

CHART).

Adjust pulley distance and alignment. Refer to

PULLEY DISTANCE AND ALIGNMENT.

To obtain maximum vehicle performance, the belt

tension must be adjusted according to specifica-

tions shown in the accompanying chart.

MODEL

DEFLECTION

†

mm (in)

FORCE

kg (lb)

All

models

32 ± 5 (1.260 ± .197) 11.5 (25)

†

FOR REFERENCE ONLY

To Check Tension

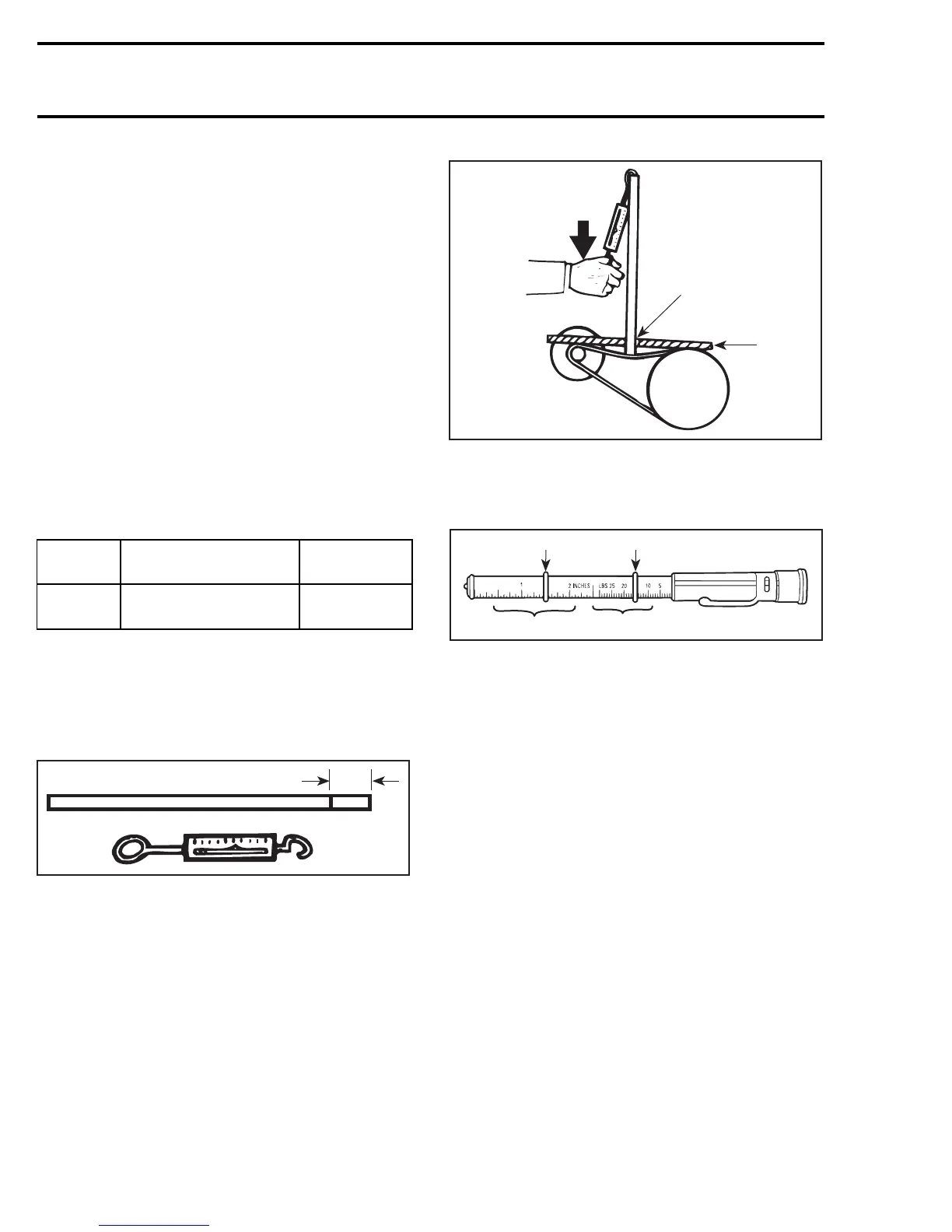

Position a reference rule on drive belt.

Wooden Stick and Spring Scale Method

A00D05A

1

1. Mark specified deflection

Using spring scale and stick, apply specified force

on drive belt halfway between pulleys as shown.

A00D06A

1

2

3

1. Force

2. Read deflection here

3. Reference rule

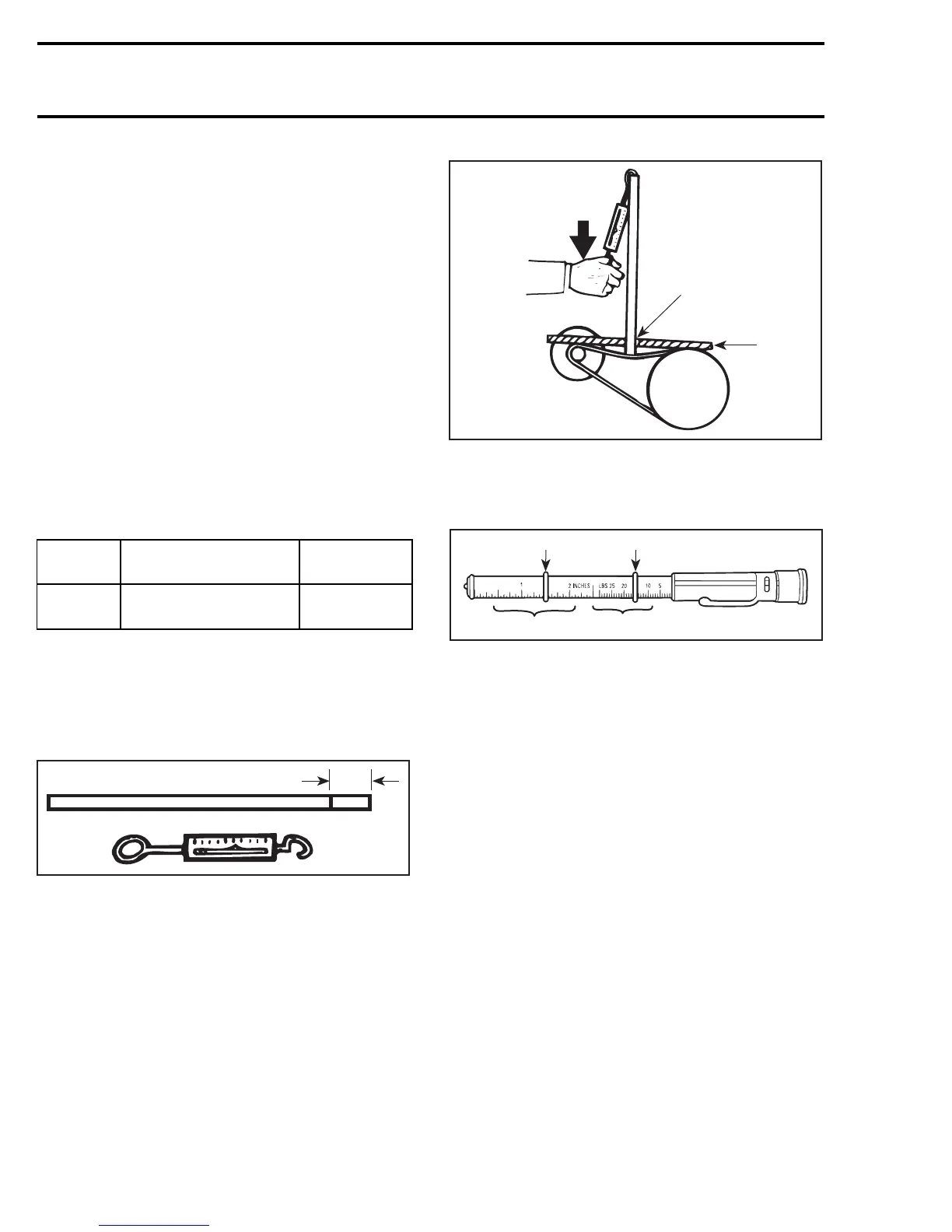

Or use the belt tension tester (P/N 414 348 200).

1

34

A00C07B

2

1. Lower O-ring

2. Upper O-ring

3. Force (read down)

4. Deflection (read up)

1) Slide lower O-ring of deflection scale to speci-

fied measure.

2) Slide upper O-ring to 0 (zero) on the force scale.

3) Apply pressure until lower O-ring is flush with

edge of rule and read force on the upper scale

at top edge of O-ring.

320 mmr2005-086

Loading...

Loading...