Section 03 ENGINES

Subsection 07 (ENGINE MEASUREMENT)

A01C0RD

1

A

TYPICAL

1. Measure at mid point between the key and the first thread

A.3mm(1/8in)

NOTE: Crankshaft deflection cannot be correctly

measured between centers of a lathe.

If the deflection exceeds the specified tolerance,

crankshaft should be repaired or replaced.

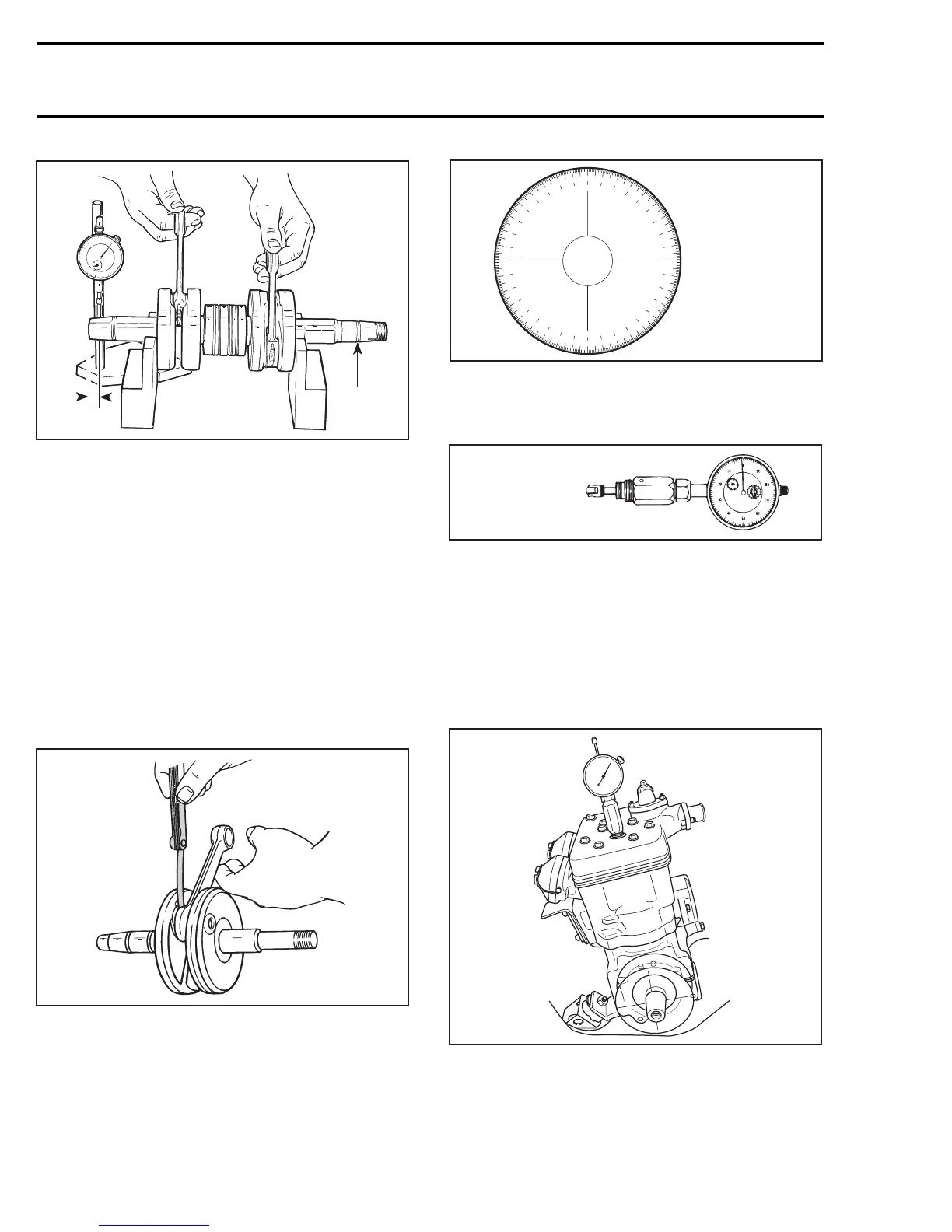

CONNECTING ROD BIG END

AXIAL PLAY

Using a feeler gauge, measure distance between

thrust washer and crankshaft counterweight. If

the distance exceeds specified tolerance, repair or

replace the crankshaft.

A01C0SA

TYPICAL

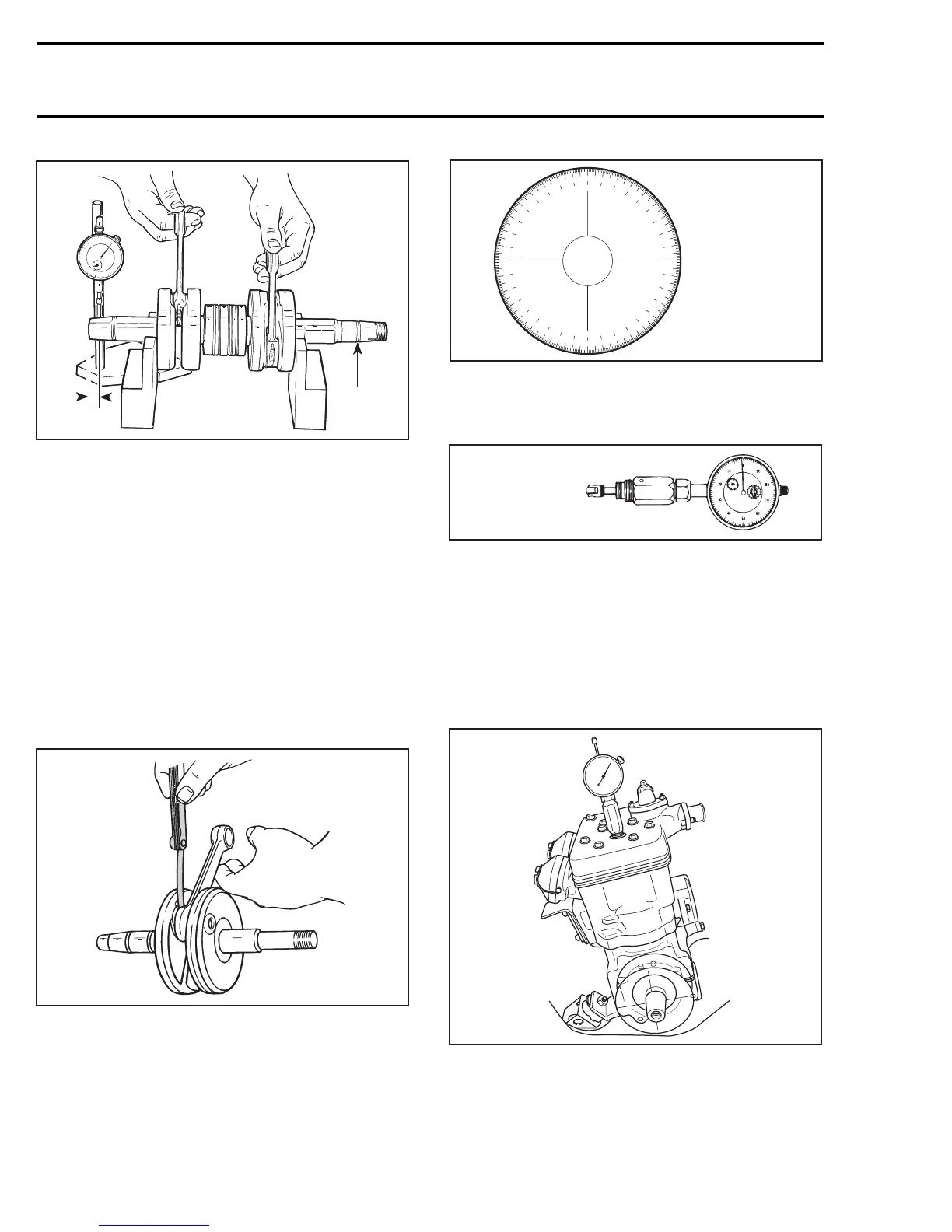

CHECKING CRANKSHAFT

ALIGNMENT

Install a degree wheel (P/N 529 035 607) on crank-

shaft end.

3

6

0

3

5

0

3

4

0

3

3

0

3

2

0

3

1

0

3

0

0

2

9

0

2

8

0

2

7

0

2

6

0

2

5

0

2

4

0

2

3

0

2

2

0

2

1

0

2

0

0

1

9

0

1

8

0

1

7

0

1

6

0

1

5

0

1

4

0

1

3

0

1

2

0

1

1

0

1

0

0

9

0

8

0

7

0

6

0

5

0

4

0

3

0

2

0

1

0

1

0

2

0

3

0

4

0

5

0

6

0

7

0

8

0

9

0

1

0

0

1

1

0

1

2

0

1

3

0

1

4

0

1

5

0

1

6

0

1

7

0

1

8

0

1

9

0

2

0

0

2

1

0

2

2

0

2

3

0

2

4

0

2

5

0

2

6

0

2

7

0

2

8

0

2

9

0

3

0

0

3

1

0

3

2

0

3

3

0

3

4

0

3

5

0

3

6

0

529 035 607

Remove both spark plugs.

Install a TDC gauge (P/N 414 104 700) in spark plug

hole on MAG side.

414 104 700

BringMAGpistonattopdeadcenter.

Rotate degree wheel (not crankshaft) so that 360°

mark aligns with center of crankcase. Scribe a

mark on crankcase.

Remove TDC gauge and install it on center cylin-

der.

Bring PTO piston to top dead center. Degree

wheel must rotate with crankshaft.

0

90

80

70

60

50

40

30

20

10

180

0

A06C1TA

TYPICAL

Interval between cylinders must be 180° ±0.5.

Any other reading indicates a misaligned (twisted)

crankshaft.

134 mmr2005-103

Loading...

Loading...