Section 09 REAR SUSPENSION

Subsection 02 (SC 3 SUSPENSION)

1

A32F15A

2

1. Protrusion

2. Stoppers

Dowel pin must exceed block guide by 2 to 2.3

mm(.079to.091in).

At installation, insert dowel pin into pivot arm hole.

2

A32F14A

13

LEFT SIDE SHOWN

1. Dowel pin

2. Pivot arm hole

3. «L» identification for left side

Respect the following tightening torque specifica-

tions:

DESCRIPTION TIGHTENING TORQUE

Locking ring set screw 2.5 N•m(22lbf•in)

Pivot arm lower nut 24.5 N•m(18lbf•ft)

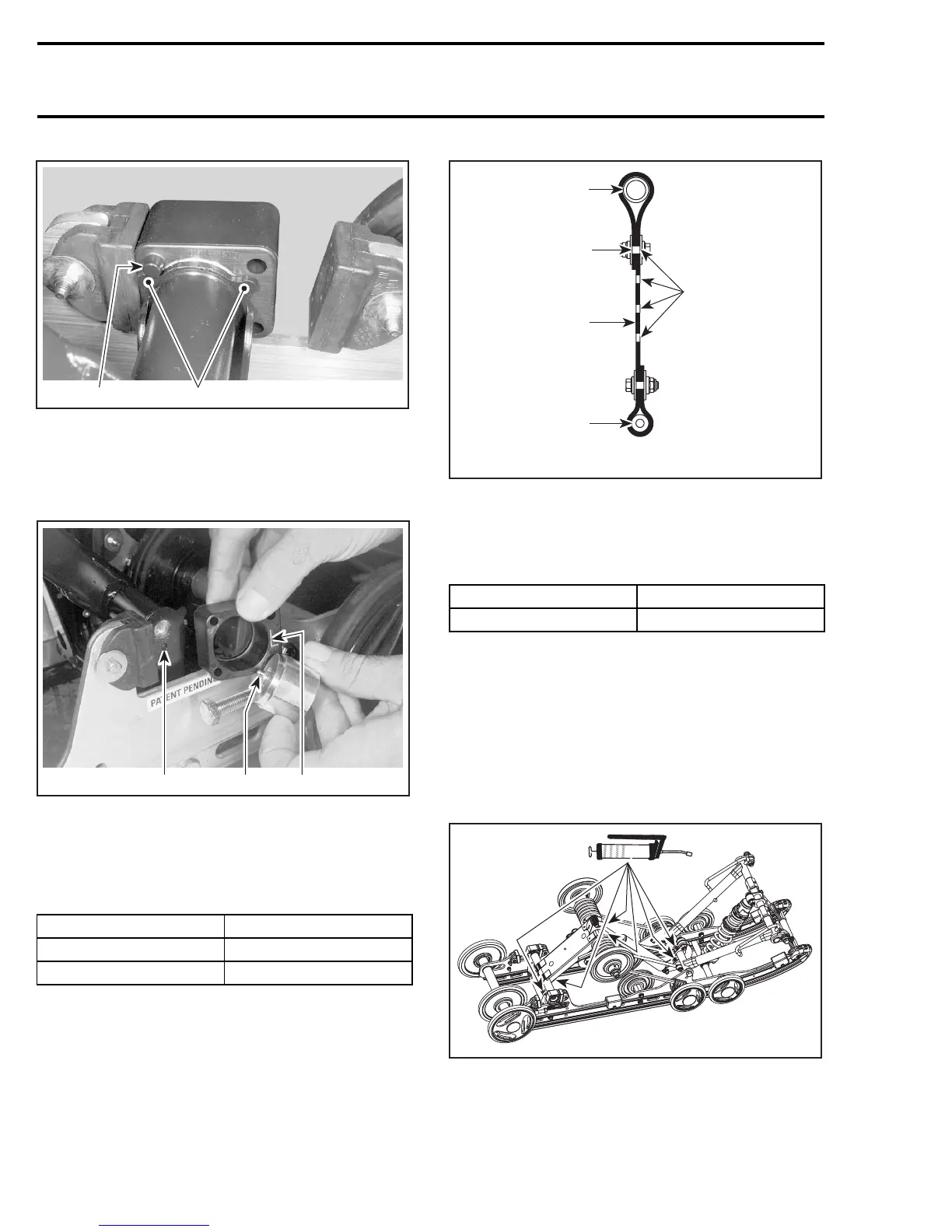

STOPPER STRAP

Inspect strap for wear or cracks, bolt and nut for

tightness. If loose, inspect hole for deformation.

Replace as required.

Make sure it is attached through proper hole from

the end.

A33F6BA

Position

4-1

1

3

2

1. Front arm (top)

2. Front axle

3. Rear of vehicle

Respect the following tightening torque specifica-

tion:

DESCRIPTION TIGHTENING TORQUE

Stopper strap nuts

11 N•m(97lbf•in)

RIDE ADJUSTMENT

Refer to the appropriate Operator’s Guide.

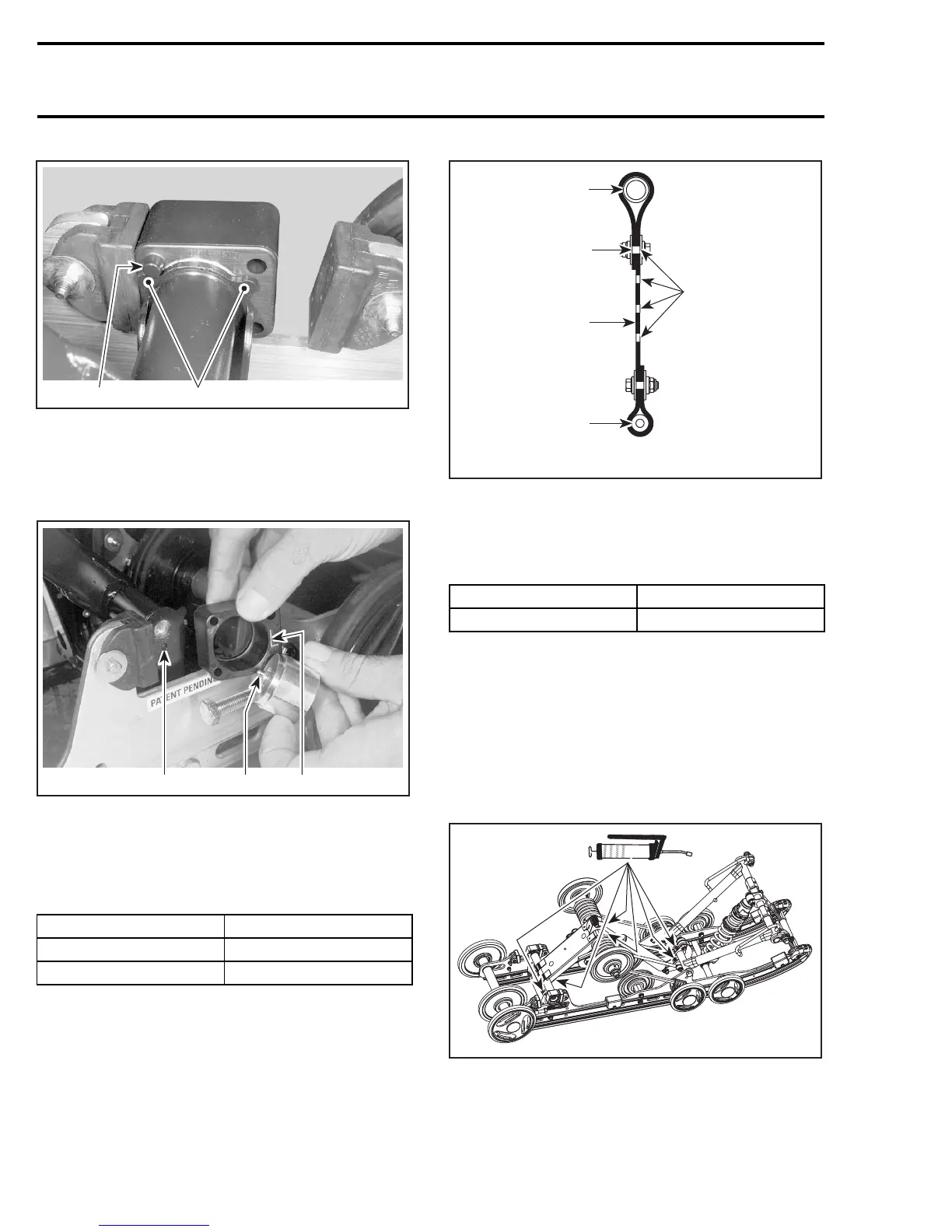

LUBRICATION

Lubricate front and rear arms at grease fittings

using suspension synthetic grease (P/N 293 550

033).

A33F68A

TYP

ICAL

406

mmr2005-095

Loading...

Loading...