Section 08 DRIVE SYSTEM

Subsection 07 (DRIVE AXLE)

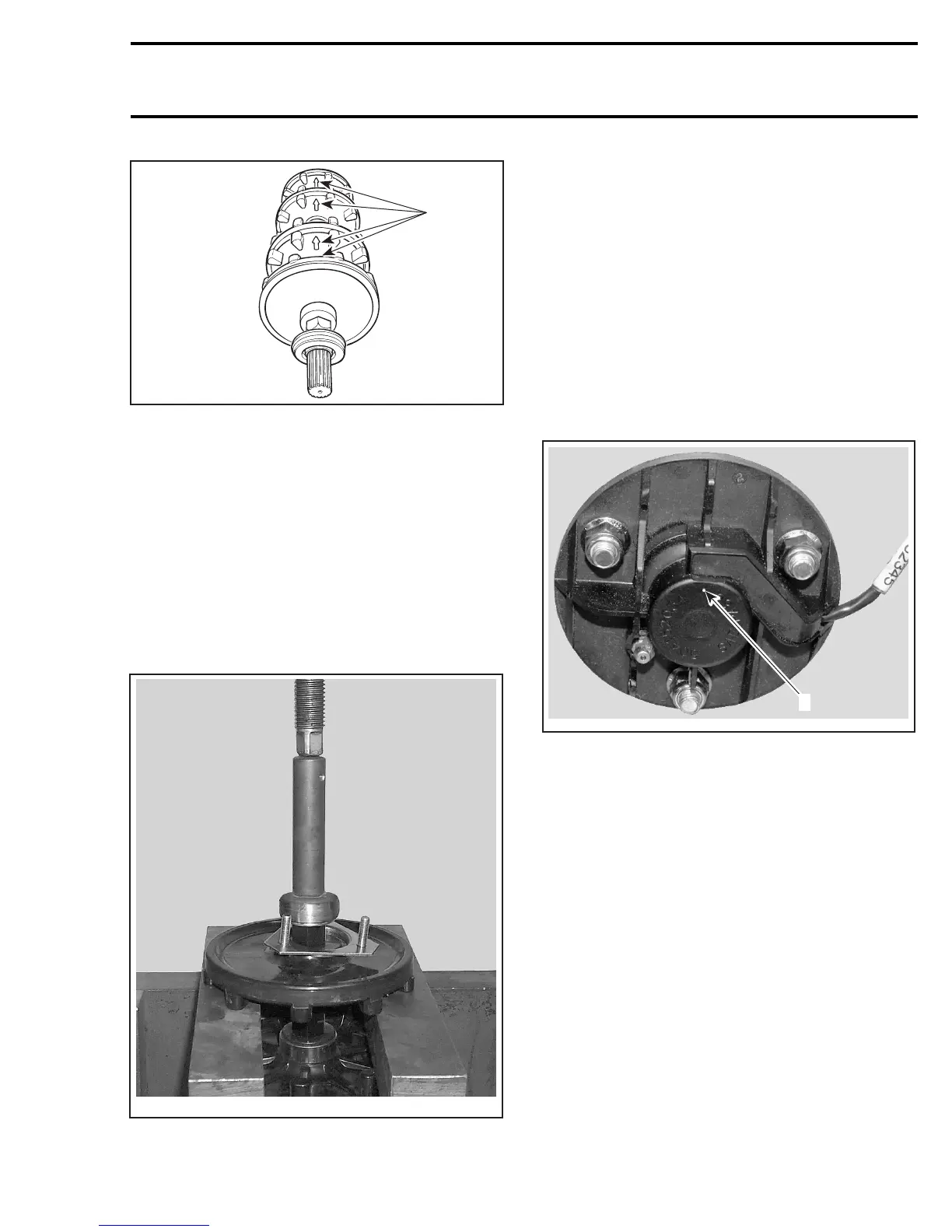

A24D05A

1

TYPICAL

1. Indexing marks aligned

CAUTION: The same sprocket must not be

pressed twice on the axle. When sprocket

has been removed from drive axle, use a new

sprocket at the installation.

Bearing Protector

At assembly, flat side of bearing protector no. 8

must be against bearing no. 9.

Bearing

Always push bearing no. 9 by inner race.

A33D0OA

The bearing no. 9 must have its shield facing the

sprocket.

The drive axle bearing in chaincase must have its

shield facing right side (cover).

Index speedometer magnetic adapter no. 4 in

drive axle and push until it is completely inserted

in its hole.

LUBRICATION

Lubricate end housing bearing with suspension

synthetic grease (P/N 293 550 033). Continue lu-

bricating until grease flows out of the pilot hole on

speedometer sensor.

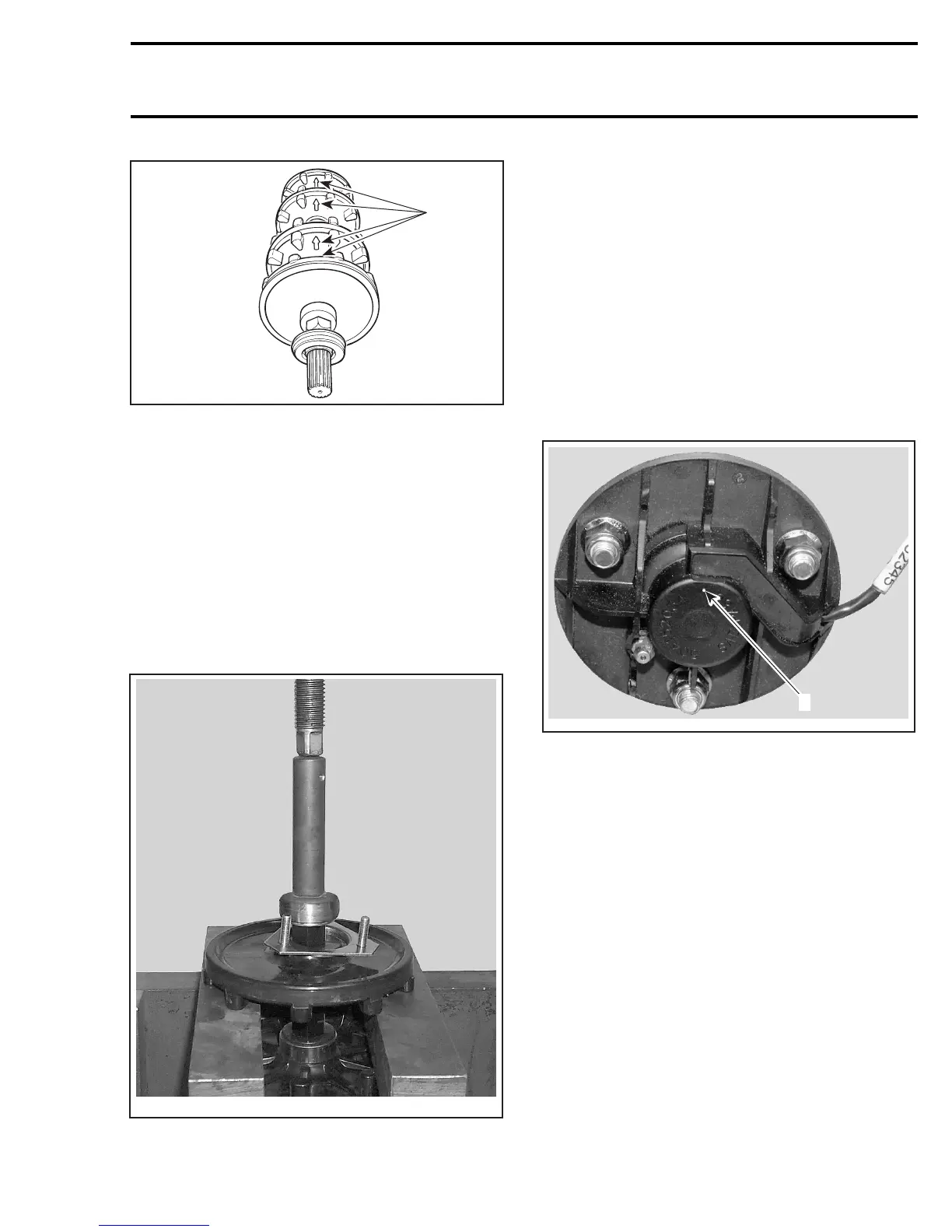

A32D44A

1

1. Lubricate until grease flows out here

ADJUSTMENT

Sprocket/Track Alignment

CAUTION: Do not tamper with sprocket/track

alignment if frame or suspension is damaged.

Sprocketsmayberepositionedtofitlugswithout

removing drive axle.

Use drive axle sprocket adjuster kit (P/N 861 725

700).

mmr2005-092 373

Loading...

Loading...