Section 03 ENGINES

Subsection 03 (ENGINE REMOVAL AND INSTALLATION)

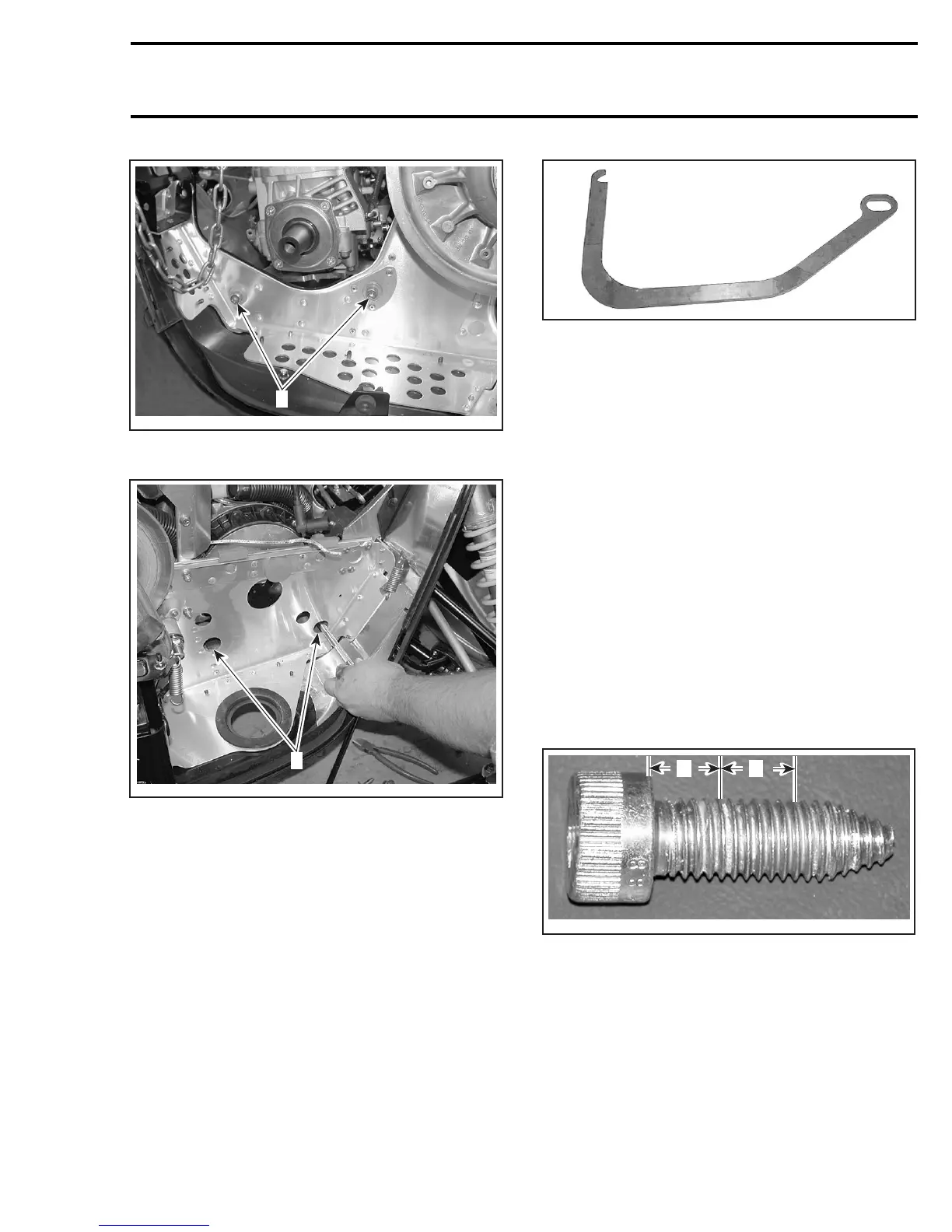

A33C2GA

1

LEFT SIDE OF VEHICLE

1. Engine support bolts

A33C2HA

1

RIGHTSIDEOFVEHICLE

1. Holes to reach engine support bolts

Unscrew the engine stopper no. 2 completely.

Lifttheenginealittlethenunplugoilpumphoses

and the crankcase vent hose.

On SDI models, disconnect all engine connectors

(CPS, WTS, KS and injectors).

Lift and slide out engine using the engine removal

hook (P/N 529 035 829).

529 035 829

Unscrew engine support nuts no. 3 then separate

support no. 4 from engine.

INSPECTION

Check if engine support no. 4 is cracked, bent or

otherwise damaged. Replace if necessary.

Check rubber mounts no. 5 on engine support.

Replace them if brittle, cracked or otherwise dam-

aged.

INSTALLATION

To install engine in vehicle, reverse the removal

procedure. However, pay attention to the follow-

ing.

Install engine support under engine then torque

engine support nuts to 35 N•m(26lbf•ft).

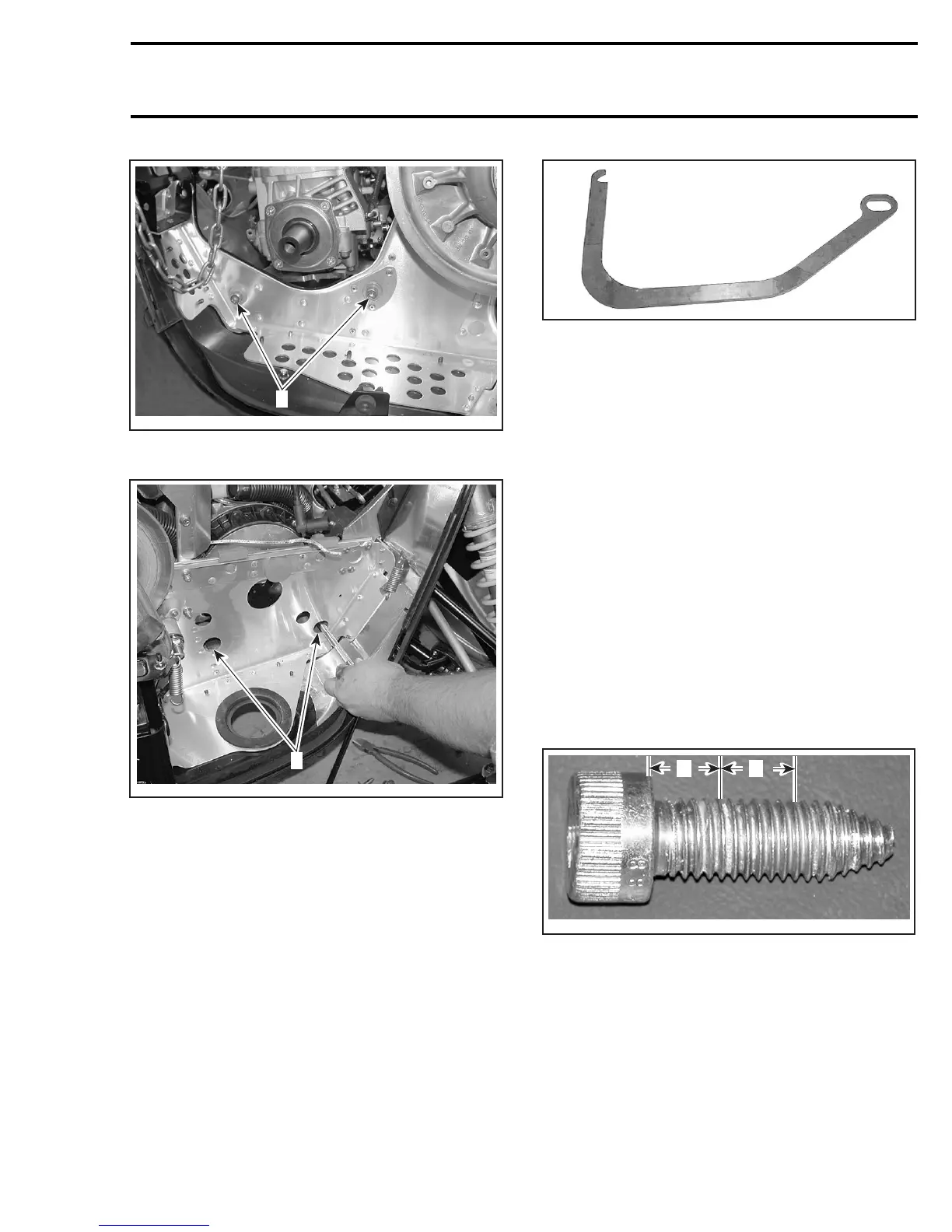

Before installing engine support bolts no. 1,apply

Loctite 243 (blue) (P/N 293 800 060) as shown in

the following illustration.

A33C2IA

A

B

A. DonotapplyLoctiteinthisarea,±10mm(.39in)

B. Loctite area, ± 8 mm (.31 in)

Torque engine support bolts to 48 N•m(35lbf•ft).

Hand torque engine stopper no. 2 then torque its

nut no. 6 to 50 N•m(37lbf•ft).

Reinstall all removed parts by using the appropri-

ate component/system reinstallation procedures

described in this shop.

mmr2005-070 69

Loading...

Loading...