Section 03 ENGINES

Subsection 06 (BOTTOM END)

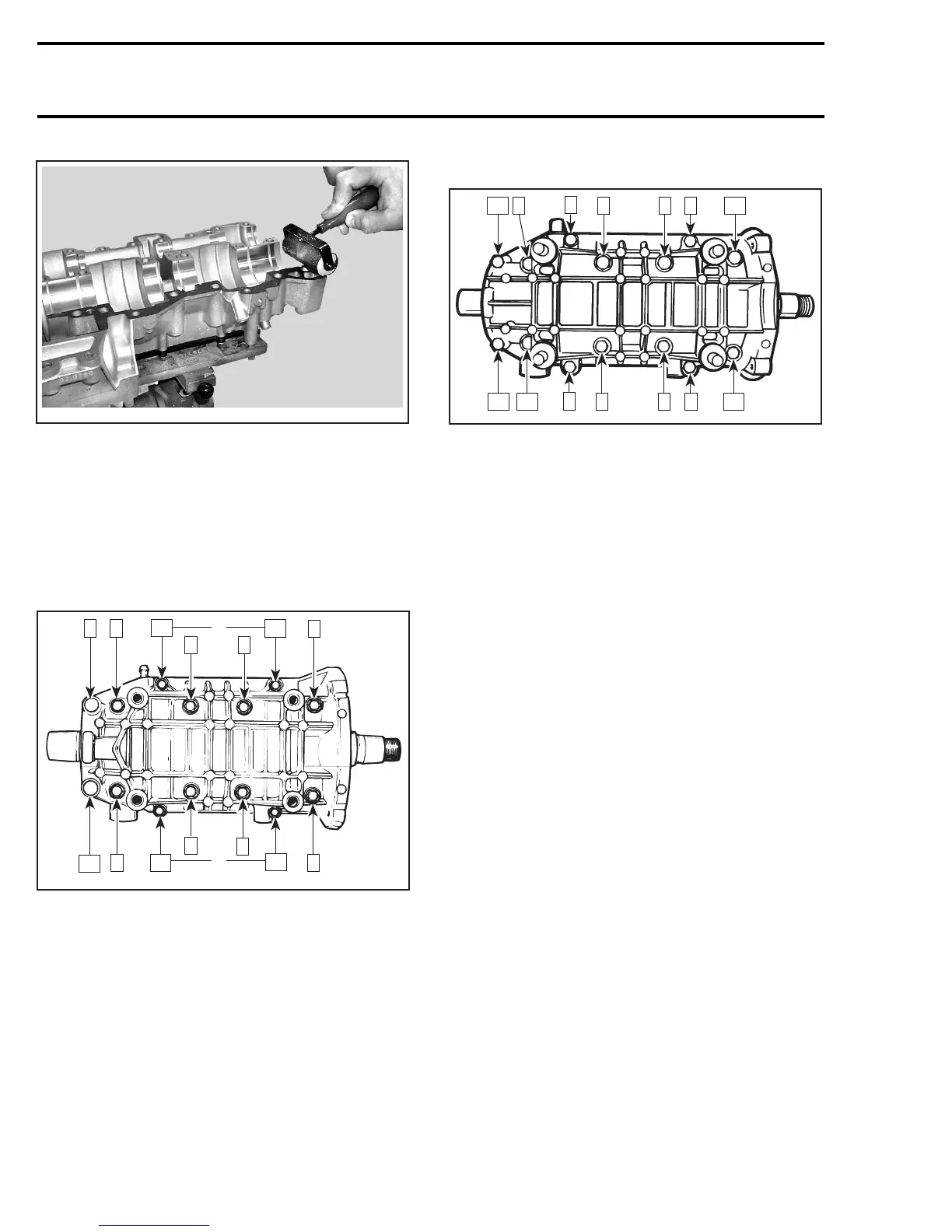

F12R18A

TYPICAL

Screw all crankcase bolts in place in the following

sequence and to the appropriate torque through a

two steps torquing: first, screw bolts up to 60%

of the final torque 13 N•m(115lbf•in)forM8

bolts), then, tighten to the required torque (i.e.

22 N•m(16lbf•ft).

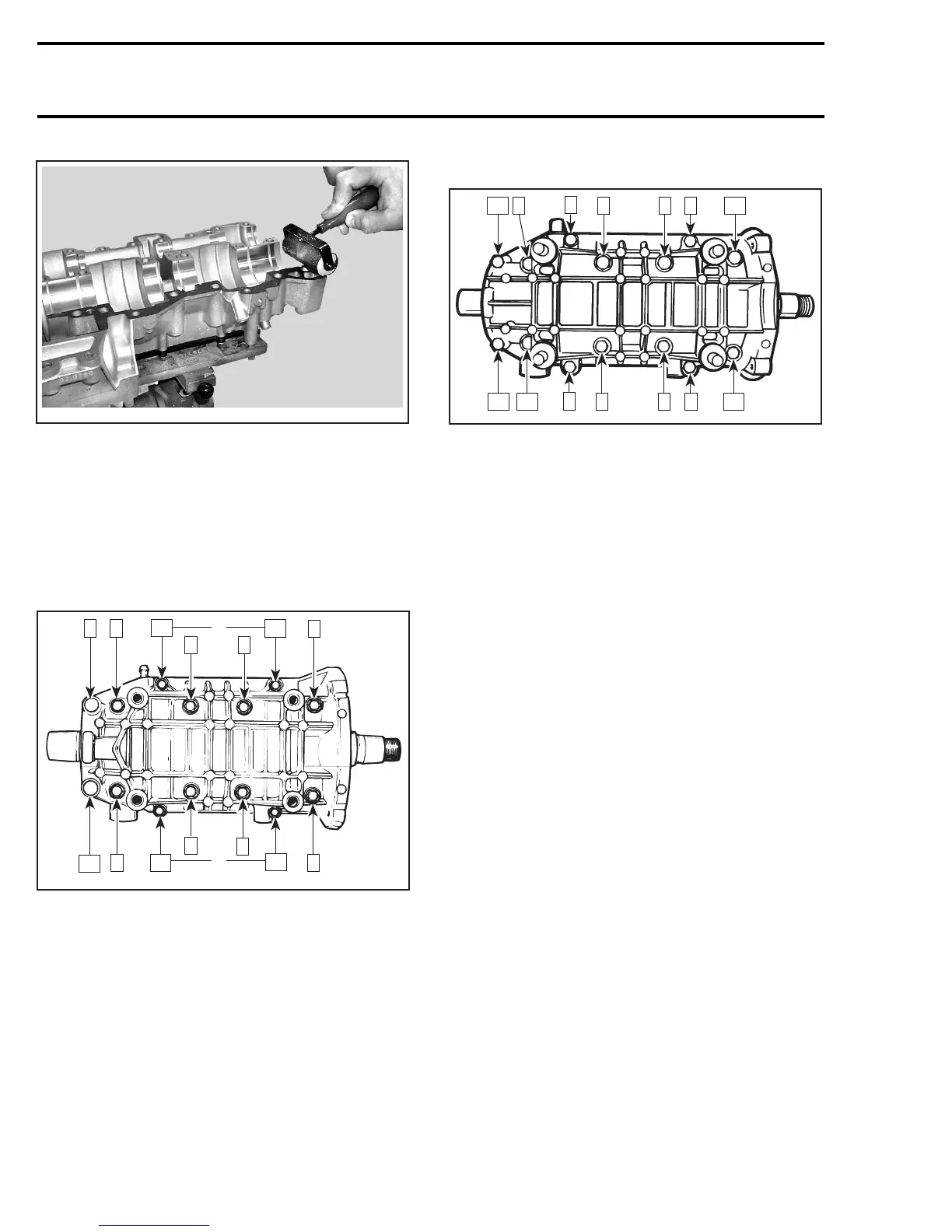

377 Engine

10

8 14

4

2

12

6

5

11

31

13

79

A

A

A09C05A

TIGHTENING SEQUENCE FOR 377 ENGINE TYPE

A. 10 N•m(89lbf•in)

All the other screws are torqued to 22 N•m

(16 lbf•ft)

552 Engine

A17C08A

1131

7

913 5

14 10

6

4 2 8 12

TIGHTENING SEQUENCE FOR 552 ENGINE TYPE

BREAK-IN

After rebuilding an engine always observe a break-

in period as described in Operator’s Guide.

118 mmr2005-073

Loading...

Loading...