Section 03 ENGINES

Subsection 04 (MAGNETO SYSTEM)

GENERAL

NOTE: The following procedures can be done

without removing the engine. To facilitate mag-

neto removal, hold drive pulley with the appropri-

ate tool.

During assembly/installation, use the torque val-

ues and service products as in the exploded

views.

Clean threads before applying a threadlocker. Re-

fer to SELF-LOCKING FASTENERS and LOCTITE

APPLICATION at the beginning of this manual for

complete procedure.

WARNING

Torque wrench tightening specifications

must strictly be adhered to.

Locking devices (e.g.: locking tabs, elastic

stop nuts, self-locking fasteners, etc.) must

be installed or replaced with new ones where

specified. If the efficiency of a locking device

is impaired, it must be renewed.

MAGNETO FLYWHEEL

Cleaning

Clean all metal components in a non-ferrous metal

cleaner.

CAUTION: Clean magneto flywheel using only

a clean cloth.

Removal

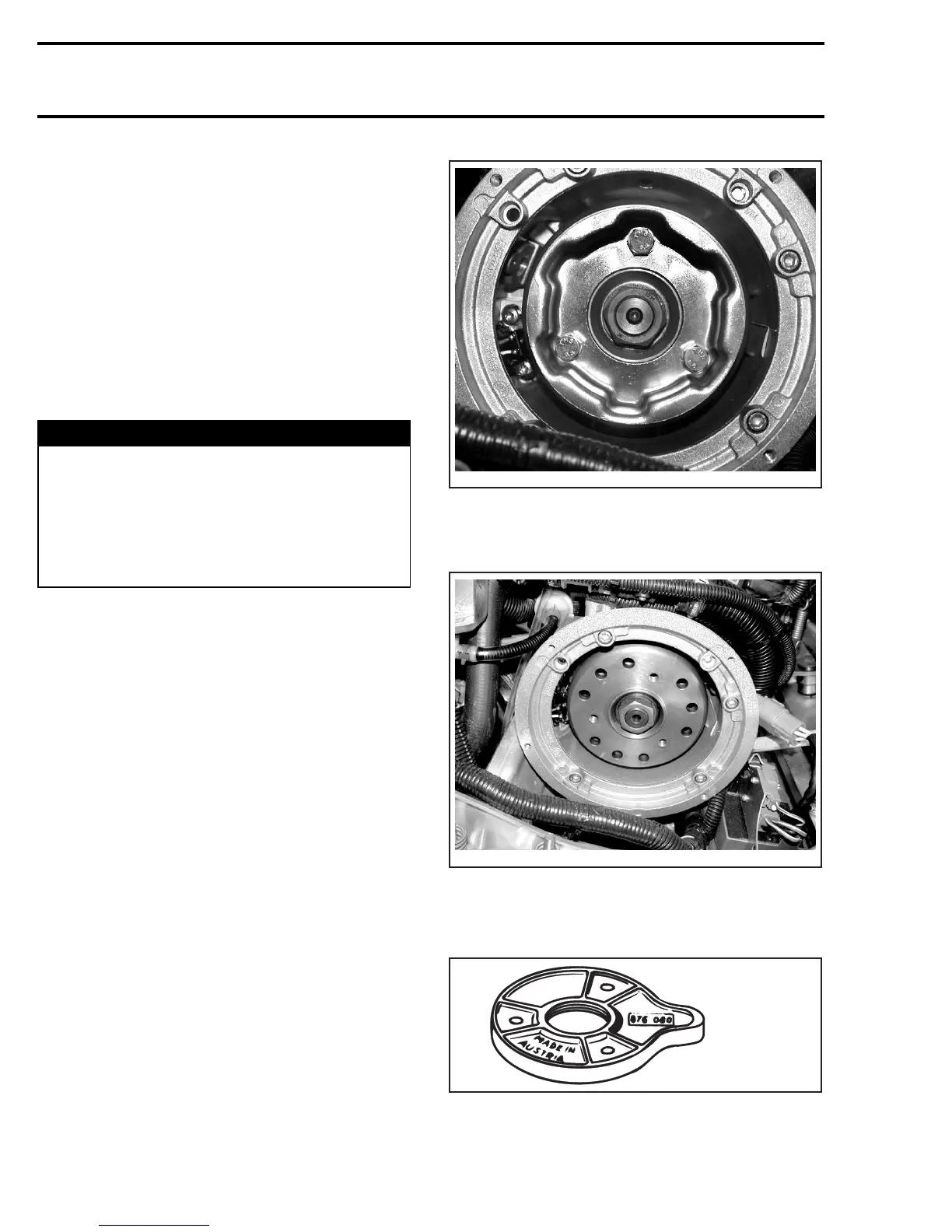

To gain access to magneto flywheel no. 1 assem-

bly, remove the following parts as needed on dif-

ferent engines:

– tuned pipe and muffler

– rewind starter

– starting pulley no. 2.

A32C8KA

TYPICAL

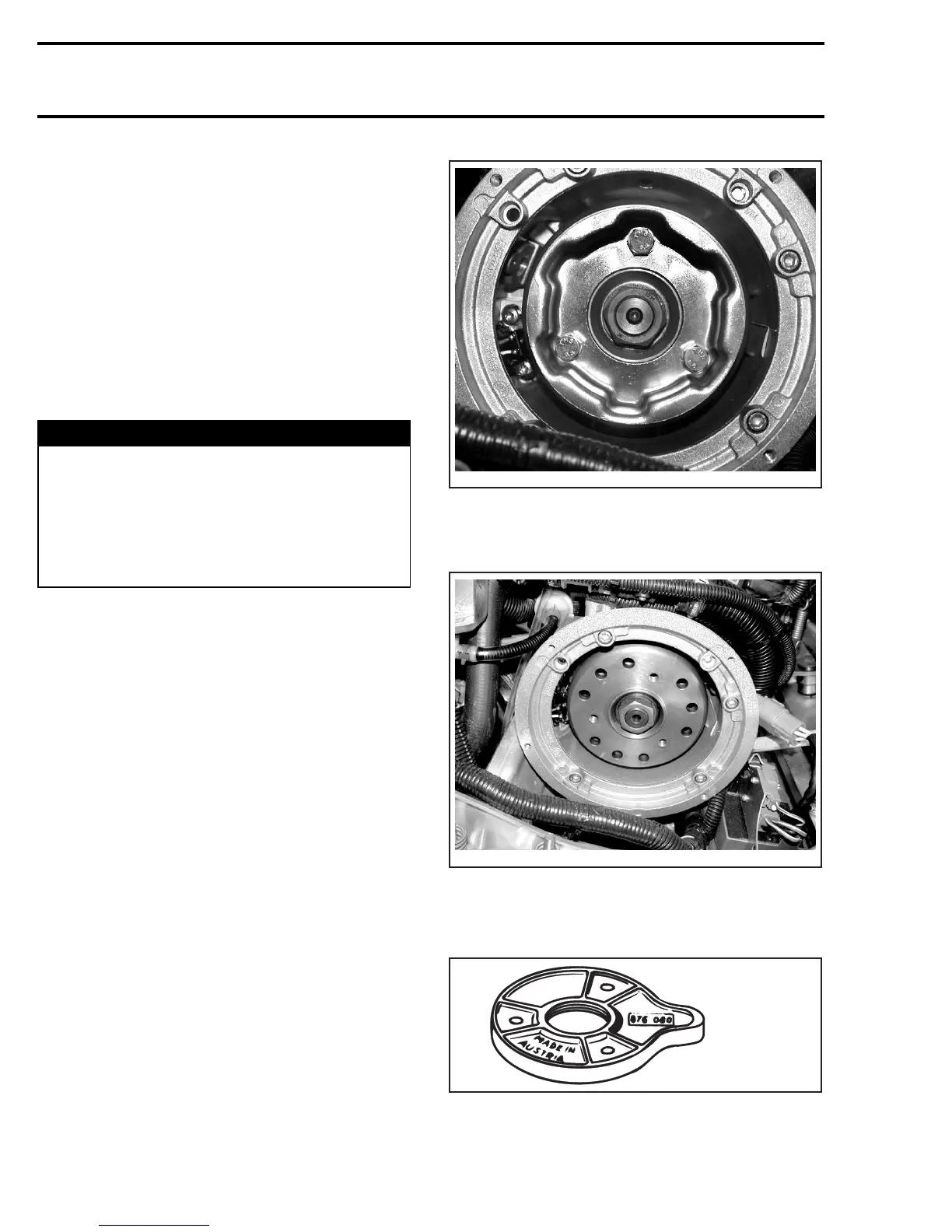

Remove the connecting flange retaining the

rewind starter to the engine housing.

A32C8LA

TYPICAL

– Install the puller ring (P/N 420 876 080) in mag-

neto housing opening.

420 876 080

76 mmr2005-071

Loading...

Loading...