Section04FUELSYSTEM

Subsection 03 (DPM SYSTEM)

1

A32C6UA

23

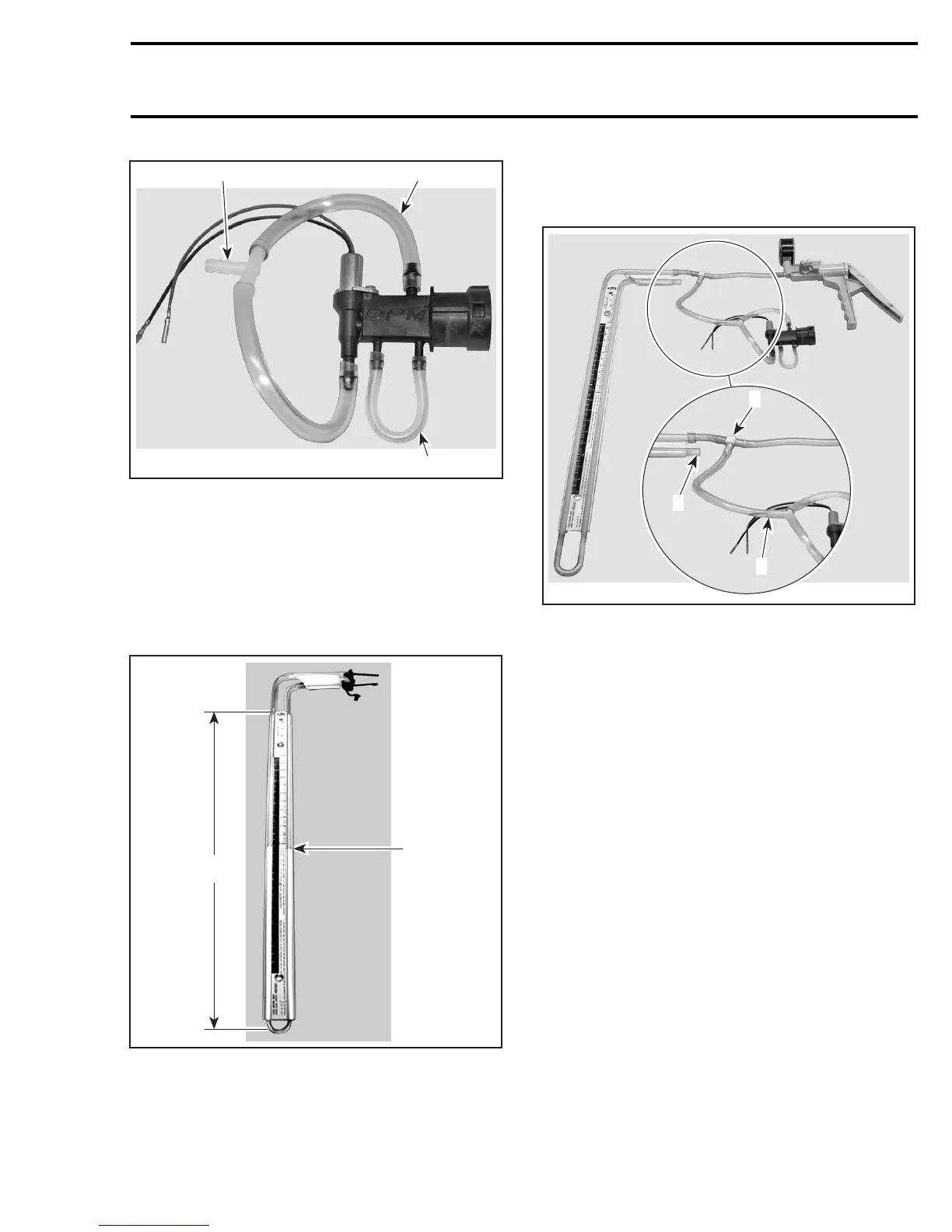

1. 3.5 mm (9/64 in) ID hose

2. 6.0 mm (15/64 in) ID hose

3. 6.0 mm (15/64 in) T-fitting

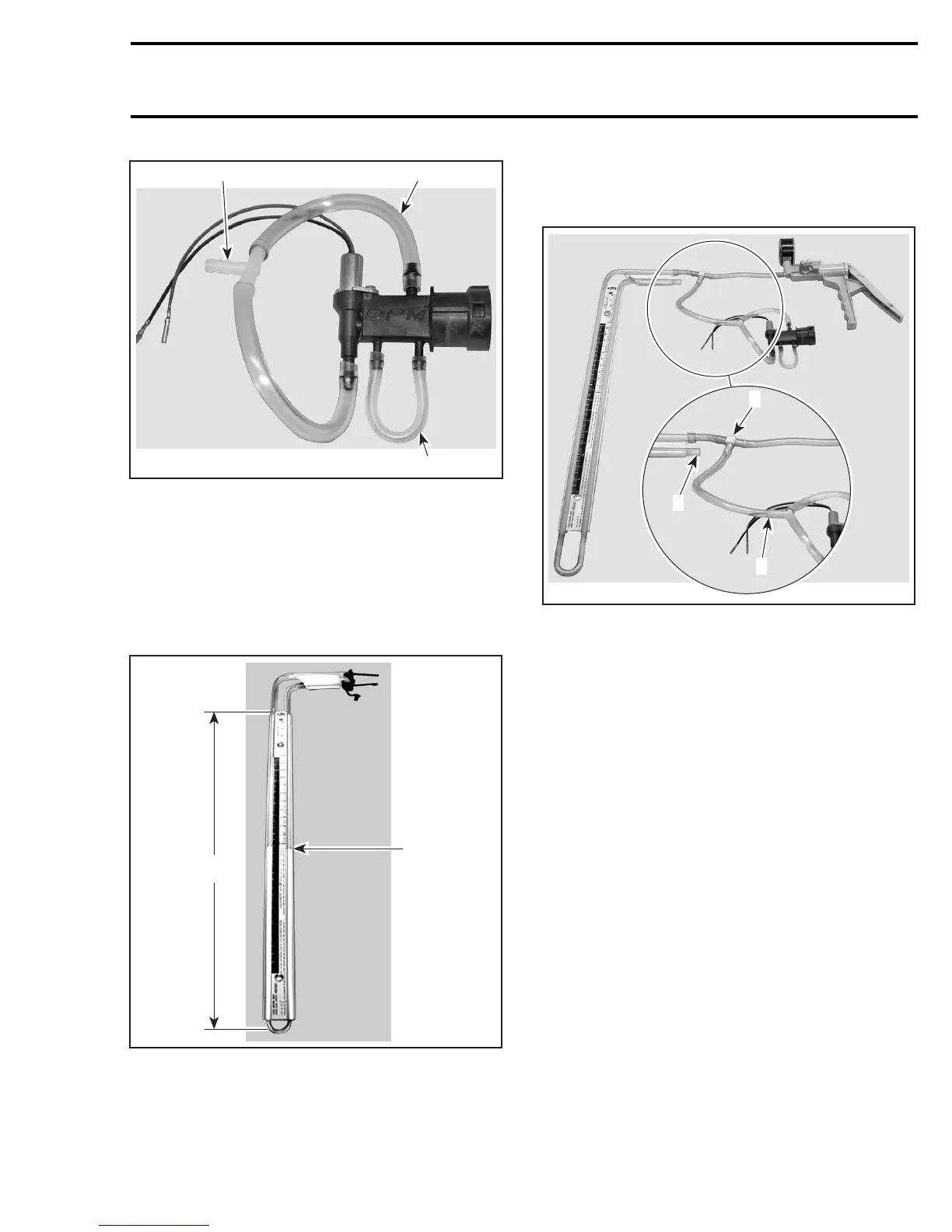

Water Column Preparation

Mount water column vertically and secure it to a

wall or workbench.

Fillwatercolumntocenterline(atleast175mm

(6-7/8 in)) in height. Refer to following photo.

A02C2ZA

1

A

1. Center line at 175 mm (6-7/8 in)

A. 350 mm (13-3/4 in)

Connecting the Pump, DPM Manifold

and Water Column

Connect hoses as shown.

A32C6YA

1

3

2

1. 4.8 mm (3/16 in) T-fitting

2. T-fitting

3. Vented to atmosphere

Collect hose into one of the water column tubes,

leave the other tube at atmospheric pressure.

Testing

Set pump to «vacuum».

CAUTION: Never use pump directly on DPM to

make a pressure test. The vacuum produced

by the pump is too high and would damage

DPM components. Use the water column as

explained above.

Apply negative pressure (vacuum) until the ex-

tremities of the water in the tube attain a differ-

ence of 350 mm (13-3/4 in).

Stop pumping and allow water levels to stabilize

in tube.

Analysis

If water level remains unchanged, the DPM man-

ifold is not defective.

If water level drops slowly to return to an even

level in more than 10 seconds, the DPM manifold

is not defective.

mmr2005-104 197

Loading...

Loading...