Section 05 ENGINE MANAGEMENT (POWER TEK)

Subsection 03 (COMPONENT INSPECTION, REPLACEMENT AND ADJUSTMENT)

Slowly and regularly depress the throttle. Ob-

serve the needle movement. It must change

gradually and regularly as you move the throttle.

If the needle “sticks”, bounces, suddenly drops

or if any discrepancy between the throttle move-

ment and the needle movement is noticed, it

indicates a worn TPS that needs to be replaced.

Voltage Test

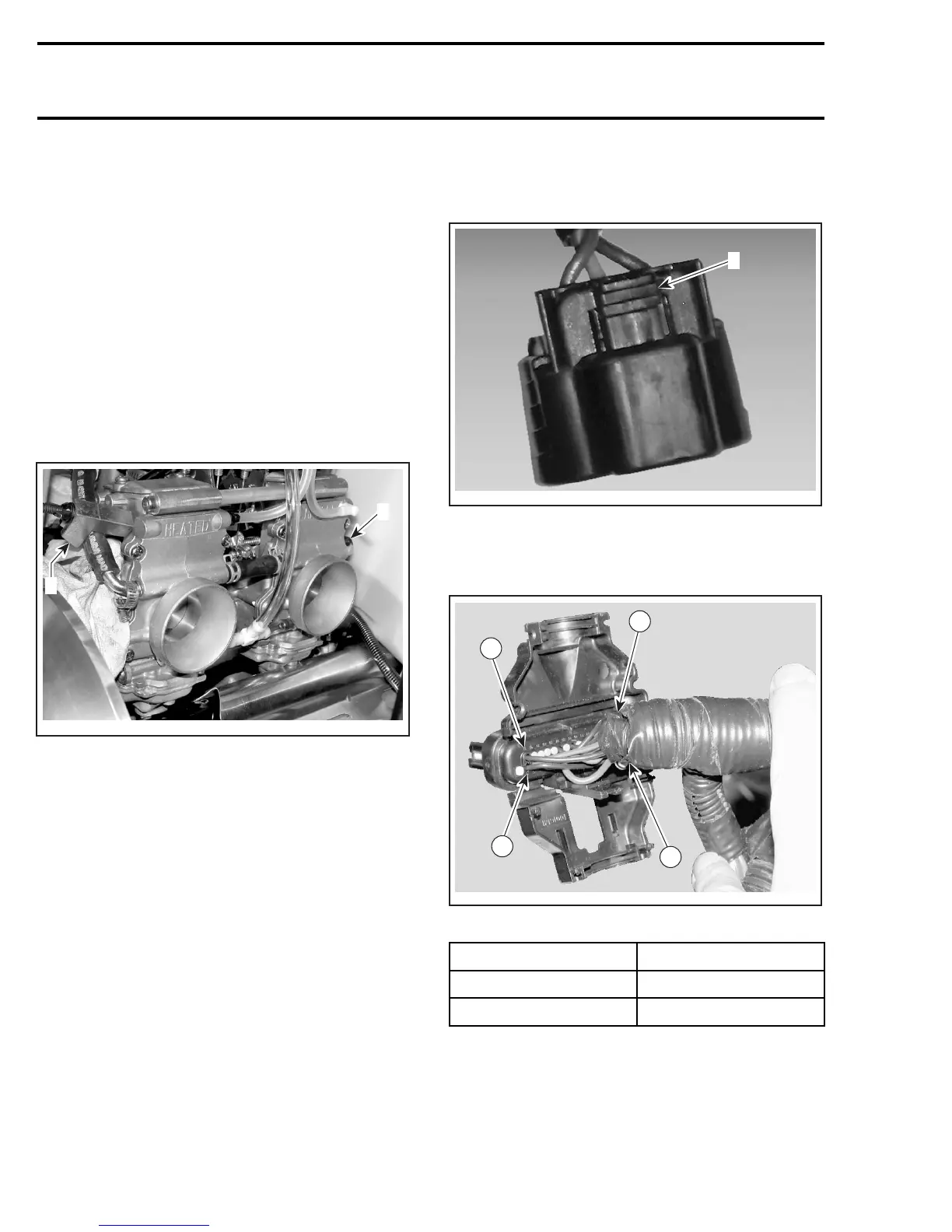

To gain access to TPS, do the following:

– remove air intake silencer

– loosen carburetor clamps

– install small hose pinchers (P/N 295 000 076)on

inlet and outlet coolant hoses connected to car-

buretor

A33C4XA

1

1

1. Install hose pinchers

– disconnect inlet and outlet coolant hoses from

carburetors

NOTE: Keep throttle cable installed to avoid fur-

ther adjustment.

– properly rotate and slightly pull out carburetors

to gain access to TPS.

Connect vehicle communication kit (VCK) and use

B.U.D.S. software.

Validation of Pins 2 and 3

Disconnect TPS connector. A fault code should

appear in B.U.D.S. If so, it confirms pins 2 and 3 of

TPS connector are working. Therefore, continue

with validation of pins 1 and 3 below. If no fault

code appears, do the following.

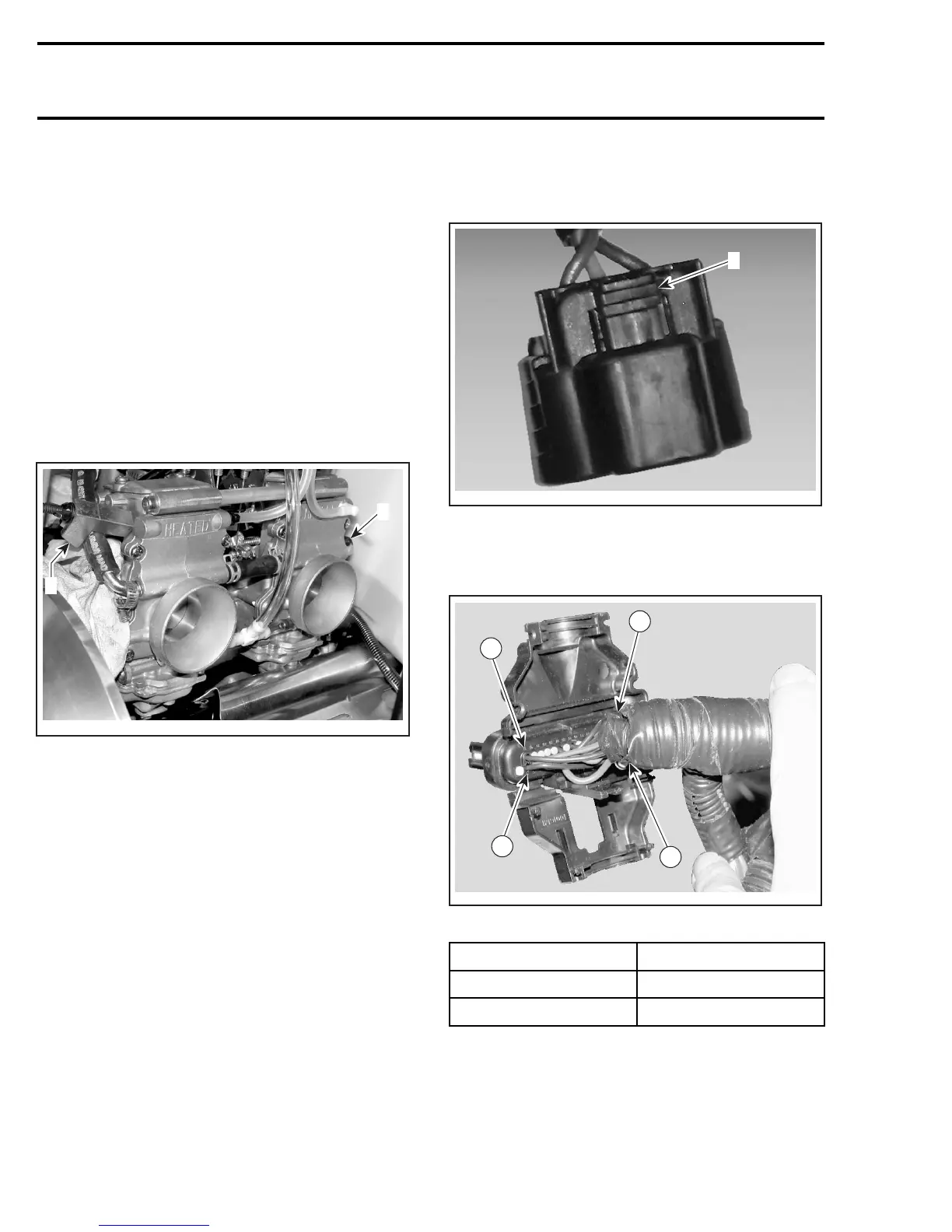

Disconnect TPS connector.

NOTE: To disconnect TPS connector, firmly press

locking tab on top outer side of connector to re-

lease it.

A33C4YA

1

1. Firmly squeeze here

Disconnect ECM connector and check continuity

of wires between TPS connector and ECM con-

nector.

A34E0LB

32

17

16

1

ECM CONNECTOR

TPS CONNECTOR ECM CONNECTOR

PIN 2 DA-4

PIN 3 DA-1

If wire/connectors does not test good, repair/re-

place wire/connector. Otherwise, try a new ECM.

218 mmr2005-107

Loading...

Loading...