Section 09 REAR SUSPENSION

Subsection 04 (SHOCK ABSORBER INSPECTION AND SERVICING)

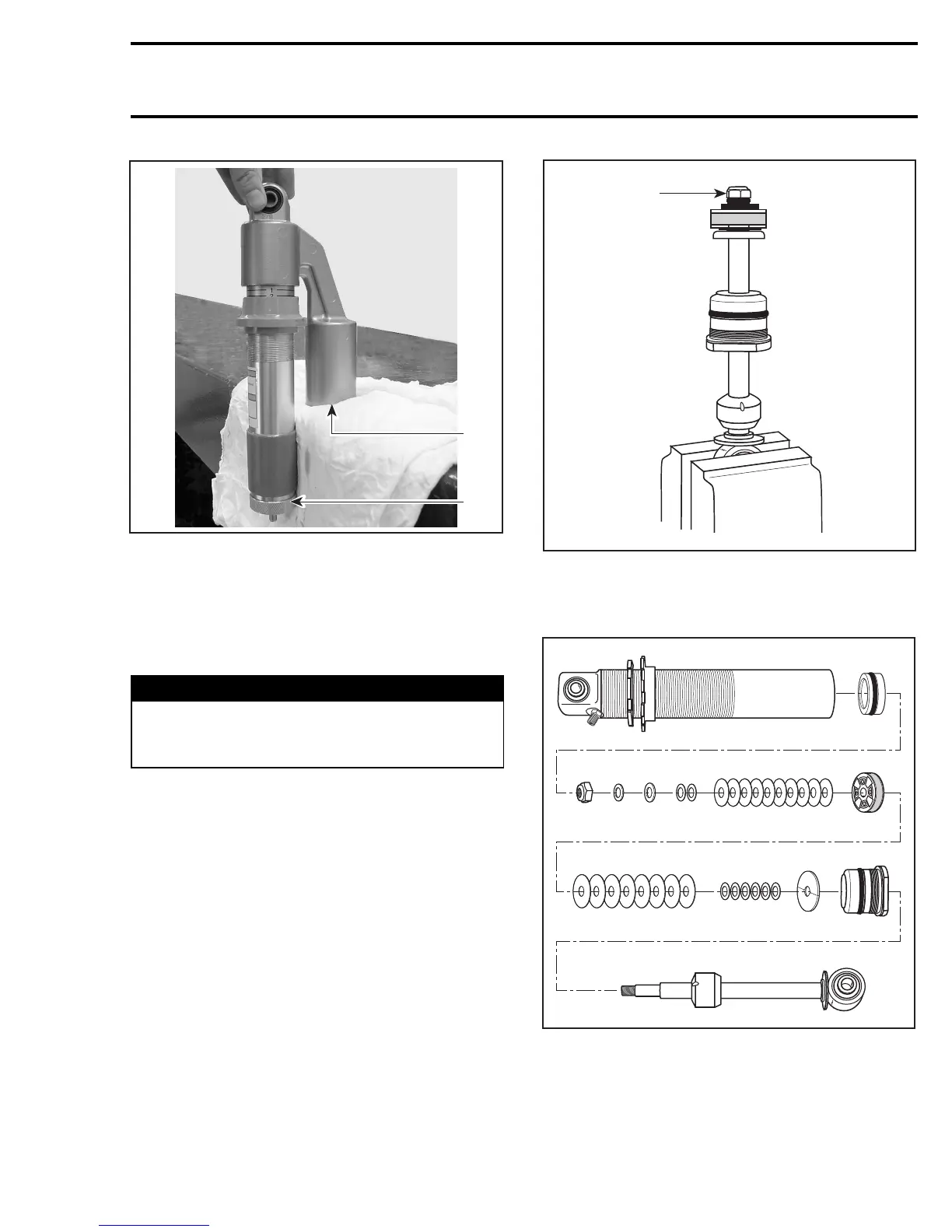

1

A32F3ZA

2

1. Tool

2. Reservoir opened extremity blocked by leaning on work bench

With a low pressure hand pump, pressurize shock

absorber until external reservoir piston pops-out.

NOTE: Use towels to prevent damaging external

reservoir piston when it pops-out.

WARNING

Whenever using compressed air, use an

O.S.H.A. approved air gun and wear protec-

tive eye wear.

Thoroughly clean, with a typical cleaning solution,

and blow dry using low pressure air. Carefully in-

spect the damper body for any imperfections or

signs of wear in the damper bore.

Replace damper body if wear is identified.

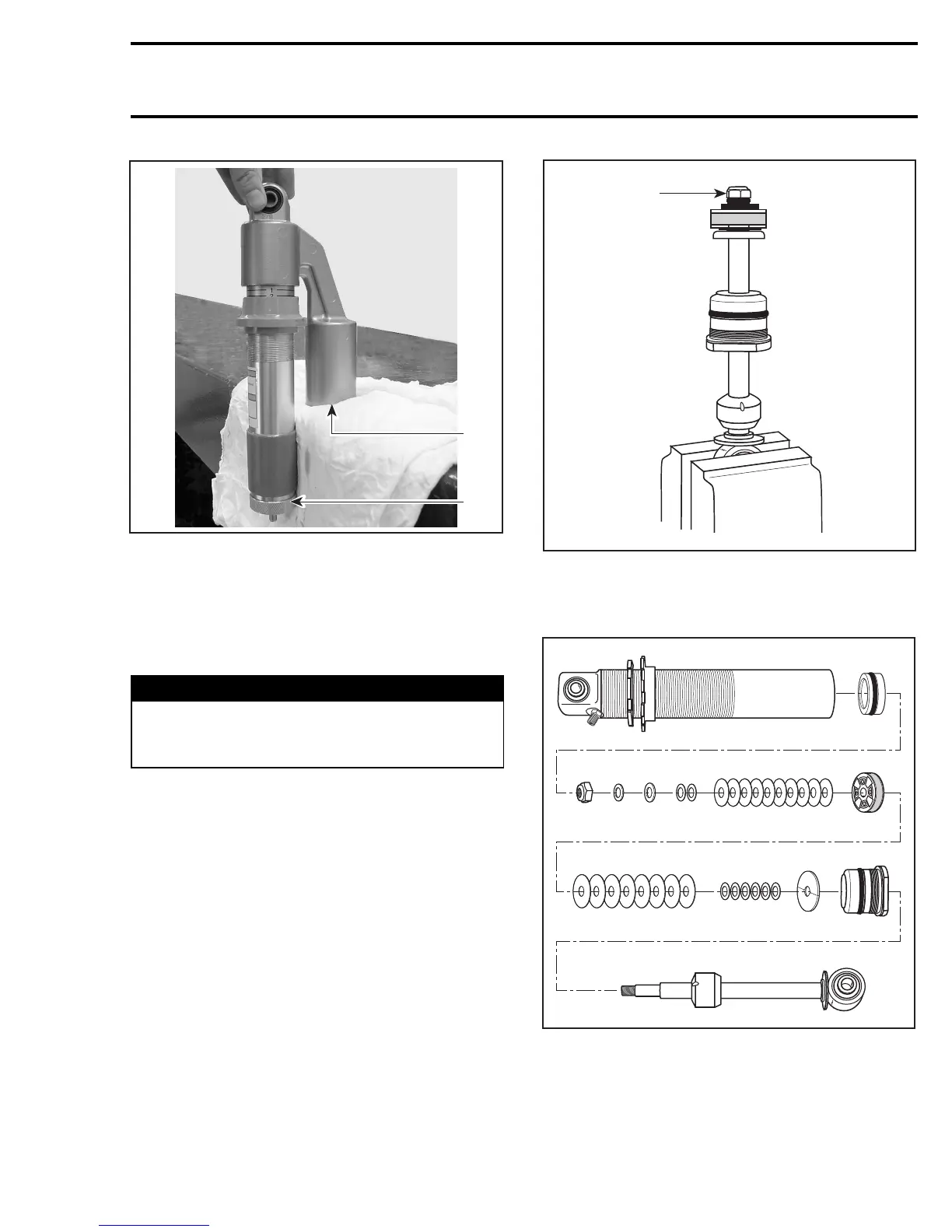

All HPG T/A Shocks

Holding the damper rod assembly in a bench vise,

begin piston and valve removal.

A06F0UA

A

A. Remove damper nut

Alwaysarrangepartsremovedinthesequenceof

disassembly.

A06F0VA

NOTE: As a general rule we suggest replacing

the damper rod lock-nut after 4 rebuilds to ensure

good Iocking friction and use Loctite 271 (P/N 293

800 005) each time.

mmr2005-108 427

Loading...

Loading...