CARBURETTOR

To maintain the efficiency of the carburettor it should

be cleaned periodically by entirely dismantling it and

washing each part in clean petrol.

Renew any worn parts, particularly in the needle

valve if the head has a distinct ridge at the point of

seating, throttle valve if excessive side play is

present or taper needle and clip, if it is possible to

rotate the needle freely in the clip. When re-

assembling, make sure that the taper needle is

refitted into the correct groove, is securely locked by

the clip, and that it enters the central hole in the top

of the jet block. Also verify that the needle valve

enters the top of the float chamber easily, the mixing

chamber flange joint is airtight, and the needle valve

clip registers correctly in it’s groove. It will, of course,

be necessary to reset pilot adjusting screw.

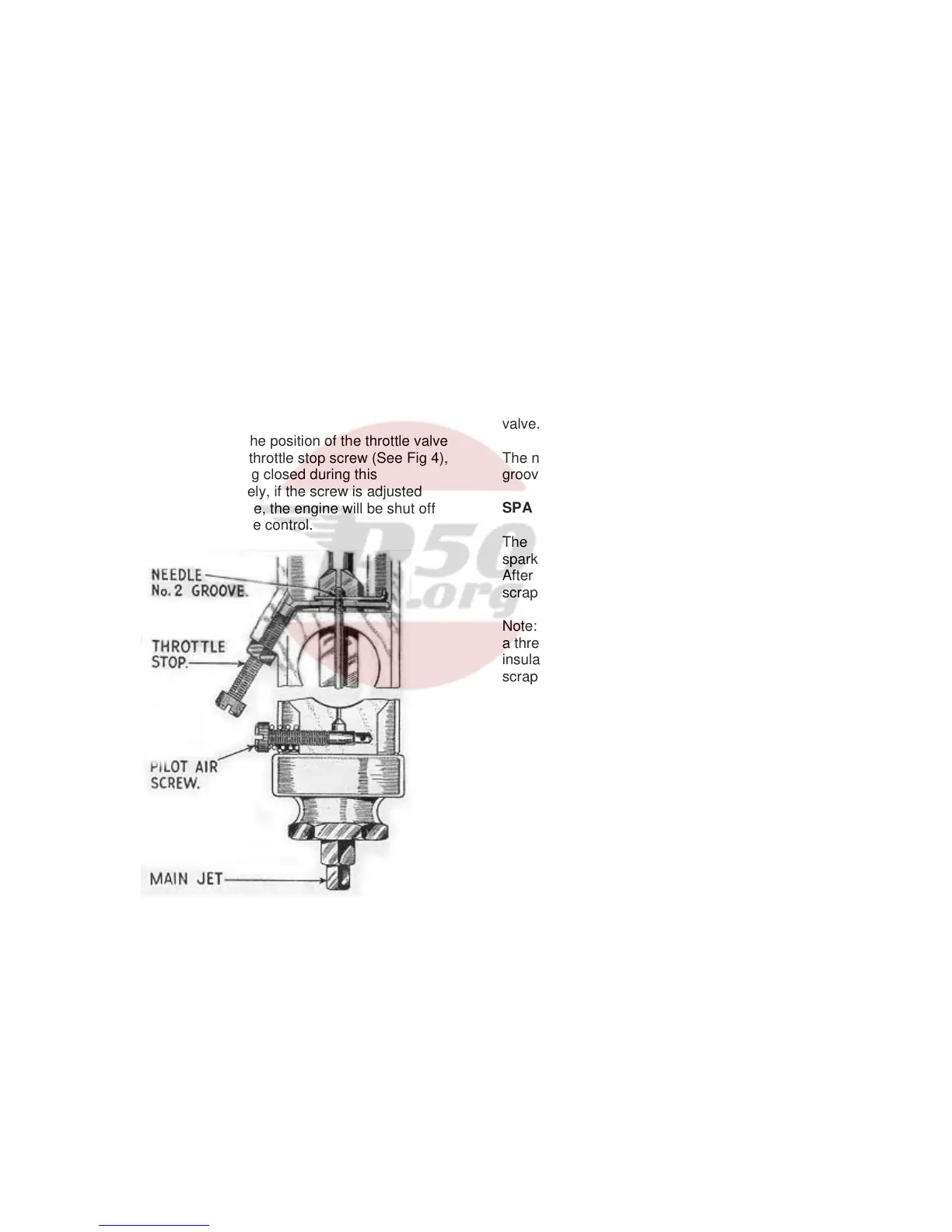

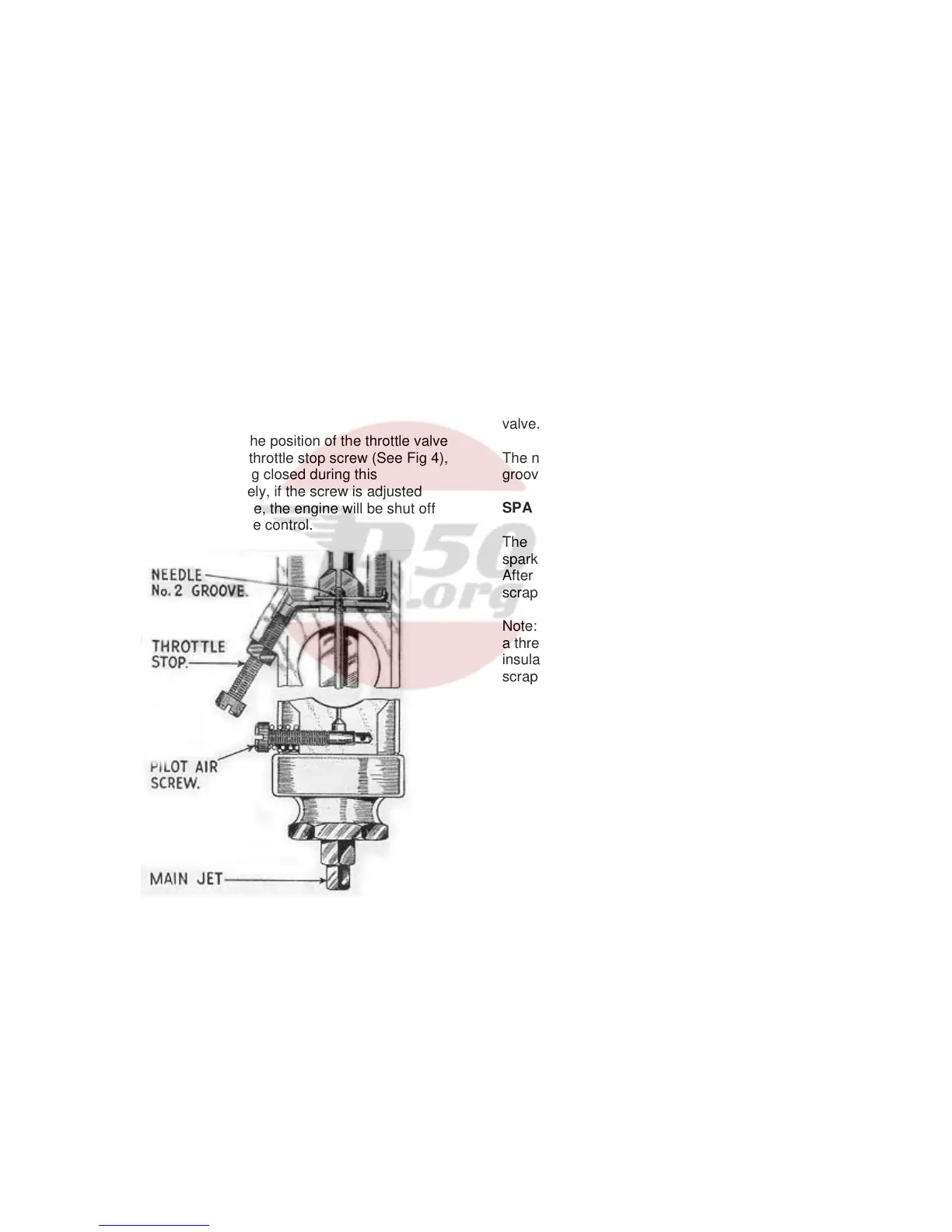

NEEDLE POSITION . Needle positions are counted

from the top of the needle and the groove nearest the

top is No. 1.

THROTTLE STOP. The position of the throttle valve

is set by means of the throttle stop screw (See Fig 4),

the throttle control being closed during this

adjustment. Alternatively, if the screw is adjusted

clear of the throttle valve, the engine will be shut off

in the normal way by the control.

Fig. 11. Carburettor adjustments.

PILOT ADJUSTMENT. To weaken the slow running

mixture, screw the pilot air adjuster outwards and to

enrich the slow running mixture, screw the adjuster

inwards.

Screw the air adjuster home in a clockwise direction.

Warm up the engine, close the air lever and set the

throttle about 1/8

th

SPARKING PLUG

open. Gently close the throttle

when the mixture will prove too rich unless air leaks

are present. Gradually unscrew the pilot air adjuster,

when the engine speed will increase and must be

again reduced by gently closing the throttle, until by a

combination of throttle positions and air adjustment,

the desired idling is secured.

MIXTURE STRENGTHS. Weak mixture is indicated

by difficult starting, a tendency for the engine to spit

back through the carburettor (indicated by blue fumes

from the air intake). The engine knocks, and runs hot

with loss of power. The spark plug electrode shows

indications of intense heat, and the mica insulation

becomes white. If spitting back occurs, raise the

needle in the throttle valve. Test by lowering the air

valve gently. Engine revs will rise when the air valve

is lowered slightly below the throttle valve.

Rich mixture indications are heavy “thumpy” running

with emission of black smoke from the exhaust pipe.

As the throttle is opened heavy blowback of fuel is

observed from the carburettor air intake. If the

engine speed does not increase progressively as the

throttle is raised, lower the needle in the throttle

valve.

The normal needle setting is with the clip in No. 2

groove.

The machine is supplied with a K.L.G. type F70

sparking plug, and is of a three-piece construction.

After dismantling, the lower (taper) portion should be

scraped clean of all carbon deposit.

Note: Earlier models are fitted with type L777 plug –

a three-point plug with mica insulation. Where mica

insulation is used, the mica must on no account be

scraped, but cleaned with petrol and a rag. The

inside of the body should be well scraped, and the

earth point cleaned.

When re-assembling, verify that the internal washer

is in place before inserting the electrode. Having

tightened the gland nut, set the earth point to give a

gap of 0.015” to 0.018”. This may mean bending the

earth point towards the centre electrode, or if the gap

is too narrow, prising it outwards. The centre

electrode must not be levered towards the earth

point. The external washer should be replaced if it is

broken or has been completely flattened.

SYMPTOMS OF MINOR PLUG TROUBLES.

Misfiring especially at high speeds and under heavy

pulling at lower speeds, invariably indicates that the

gap setting of the plus is too wide, whilst erratic slow

running can be accounted for by too narrow a gap

setting. An over rich mixture will result in trouble in

the form of an excess deposit of soot on the internal

insulation of the plus with consequent “shorting”

inside the plug. A faulty high tension cable, or the

magneto contact points being out of adjustment will

also account for the plug misfiring.

10

Loading...

Loading...