After setting, by slackening or tightening the securing

nut (F, Fig 49) prevent further movement by bending

up the tab of the lock washer (E). Refit the dynamo

and pack the gears with high melting point grease.

Secure the drive end cover in position with the gasket

correctly located between the cover and the end of

the magdyno.

Replace the pick-up, first checking that the brush

moves freely and that the cork gasket is free from

cracks.

Refit the earthing brush (Fig 52).

CHARGING (Section B)

DYNAMO TYPE E3HM

B (1) Dynamo Testing in Position

(a) Check that the Dynamo and regulator unit are

wired correctly. The dynamo terminal “D” should be

connected to the regulator unit terminal “D” and

dynamo terminal “F” to the regulator unit terminal “F”.

(b) Remove the cables from the dynamo terminals

“D” and “F” and connect the two terminals with a

short length of wire.

(c) Start the engine and set to run at normal idling

speed.

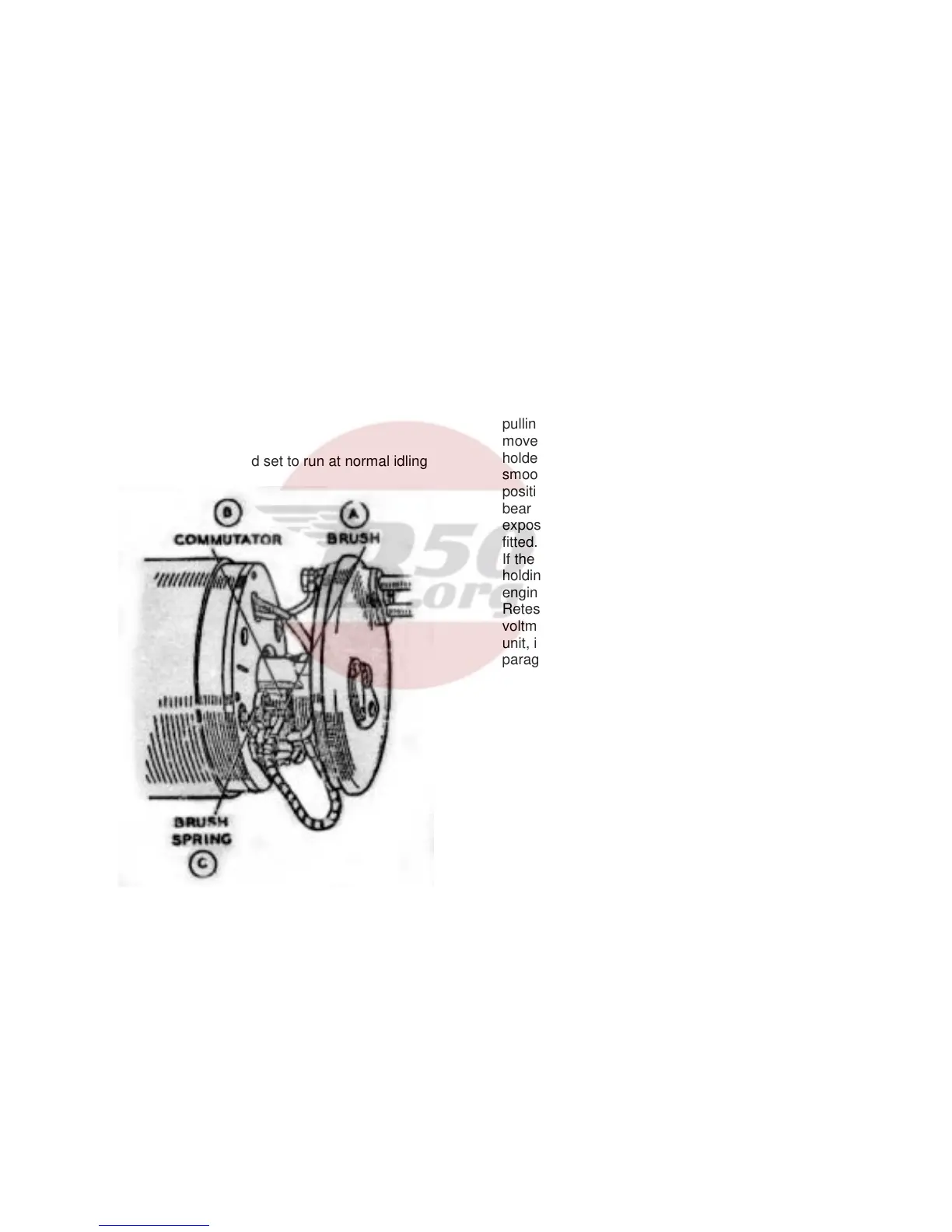

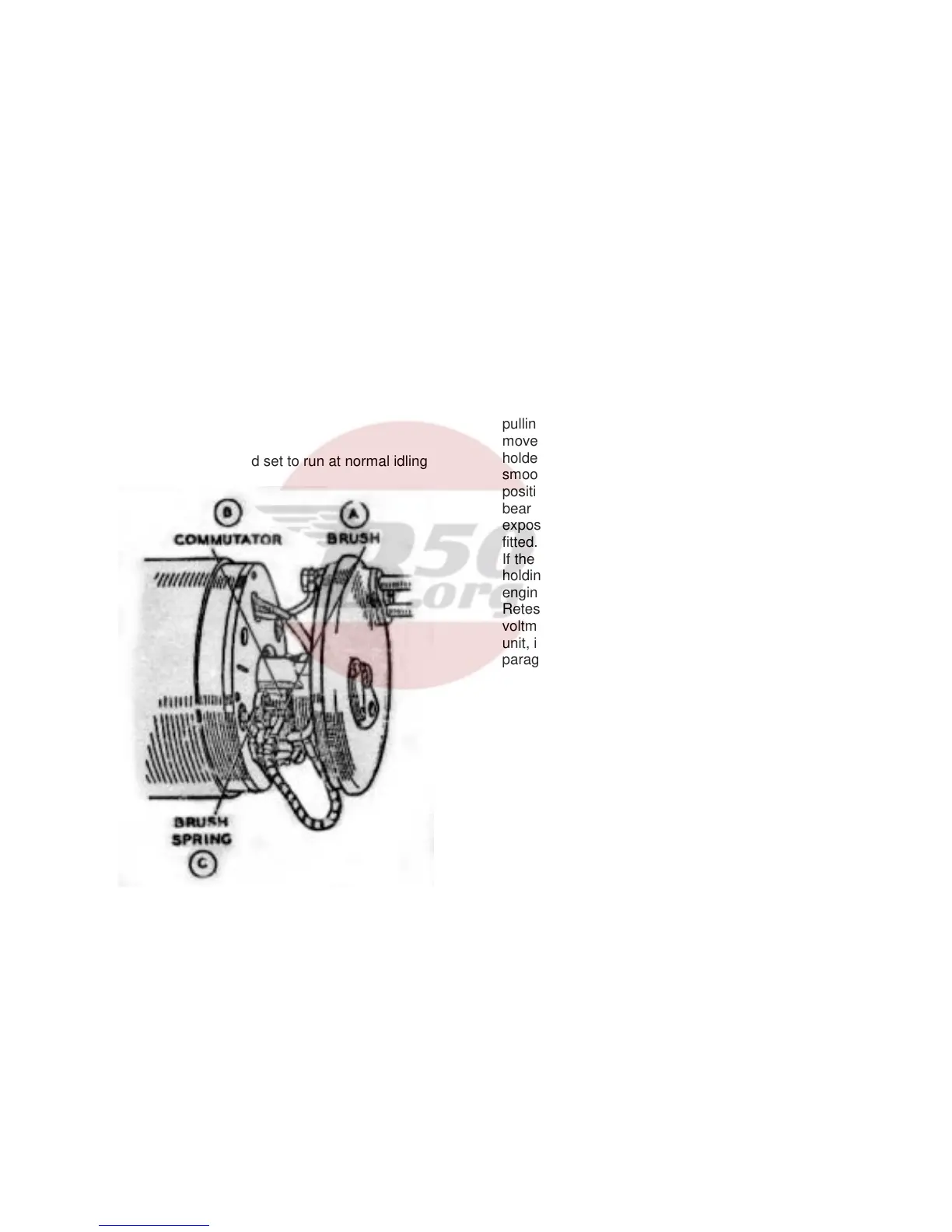

Fig. 58. Dynamo with cover band removed to

show brush gear.

(d) Connect the positive lead of a moving coil

voltmeter calibrated not less than 1-10 Volts to one of

the dynamo terminals and connect the negative lead

to a good earthing point on the dynamo yoke or

engine.

(e) Gradually increase the engine speed, when the

voltmeter reading should rise rapidly and without

fluctuation. Do not allow the voltmeter reading to rise

above 10 volts. Do not race the engine in an attempt

to increase the voltage. It is sufficient to run the

dynamo up to a speed of 1,000 rpm. If there is no

reading, check the brush gear as described in

paragraph 1 (f). If there is a low reading of

approximately ½ Volt, the field winding may be at

fault. If there is a reading of approximately 1 ½ to 2

Volts, the armature winding may be at fault.

(f) Remove the dynamo cover band and examine the

brushes (A, Fig 58) and commutator (B). Hold back

each of the brush springs (C) and move the brush by

pulling gently on its flexible connector. If the

movement is sluggish, remove the brush from its

holder and ease the sides by lightly polishing on a

smooth file. Always replace brushes in their original

positions. If the brushes are worn so that they do not

bear on the commutator, or if the brush flexible is

exposed on the running face , new brushes must be

fitted.

If the commutator is blackened or dirty, clean it by

holding a petrol moistened cloth against it while the

engine is turned slowly by means of the kickstart.

Retest the dynamo; if there is still no reading on the

voltmeter, there is an internal fault and the complete

unit, if a spare is available, should be replaced – see

paragraph B (2).

(g) If the dynamo is in good order, restore the

original connections to the dynamo. Connect

regulator unit terminal “D” to dynamo terminal “D”

and regulator terminal “F” to dynamo terminal “F”.

Remove the lead from the “D” terminal on the

regulator unit and connect the voltmeter between this

cable and an earthing point on the engine. Run the

cable as before. The reading should be the same as

that measured directly at the dynamo. No reading

indicates a break in the cable to the dynamo. If the

reading is correct, test the regulator unit – see

paragraph B (11), page 41.

B (2) Dynamo To remove and replace.

Take off the connections from the dynamo terminals,

unscrew the hexagon headed nut (A1, Fig 51) from

the driving end cover of the magdyno, slacken the

two screws (B1, Fig 51) securing the band clip and

draw the dynamo out of its mounting.

When replacing, slide the dynamo through the band

clip so that fixing screw (A, Fig 59) passes through its

hole in the end cover and the gears mesh correctly.

Tighten the end nut and the band clip fixing screws

and remake the connections to the dynamo terminals

38.

Loading...

Loading...