A (14) Re-assembling.

Wash the bearings in petrol, dry thoroughly and

repack with high melting point grease. Fit ball races

on armature shaft by means of a hand press and use

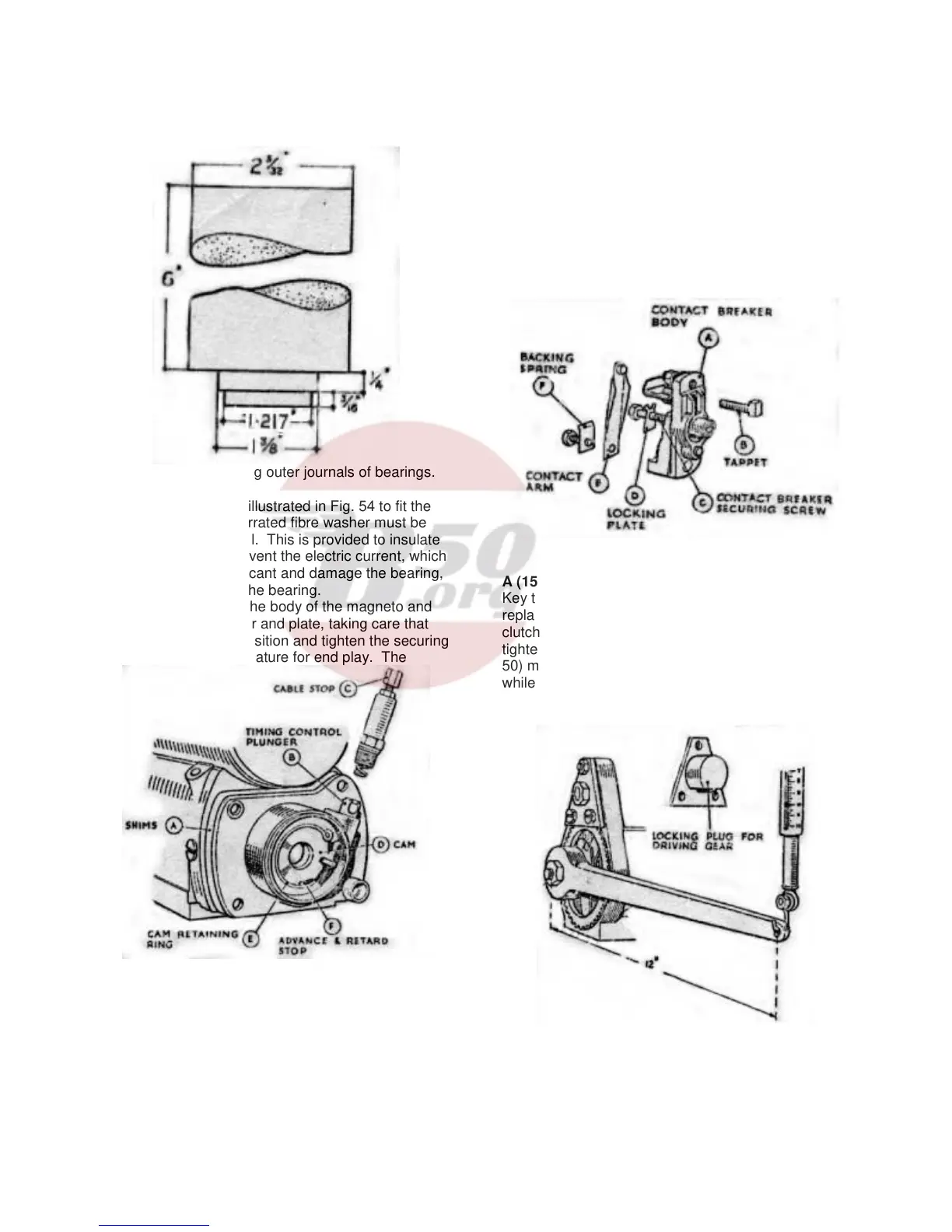

Fig. 54. Tool for fitting outer journals of bearings.

a mandrel of the type illustrated in Fig. 54 to fit the

outer journals. The serrated fibre washer must be

fitted behind the journal. This is provided to insulate

the bearing and so prevent the electric current, which

would destroy the lubricant and damage the bearing,

from passing through the bearing.

Place the armature in the body of the magneto and

refit the contact breaker and plate, taking care that

the end shims are in position and tighten the securing

screws. Check the armature for end play. The

Fig. 55. Magneto contact breaker end showing

fitting of cam, timing control and shims.

armature should revolve freely when turned by hand

but no end play should be felt. Adjust by adding or

removing shims (A, Fig. 55) and spring and secure

by tightening the cable stop (C). Locate the cam (D)

in the contact breaker housing with the timing control

plunger in its correct slot as shown in Fig. 55 and

secure by springing the circlip (E) into its location in

the housing. (Note that the cam is fitted with its flat

side towards the armature).

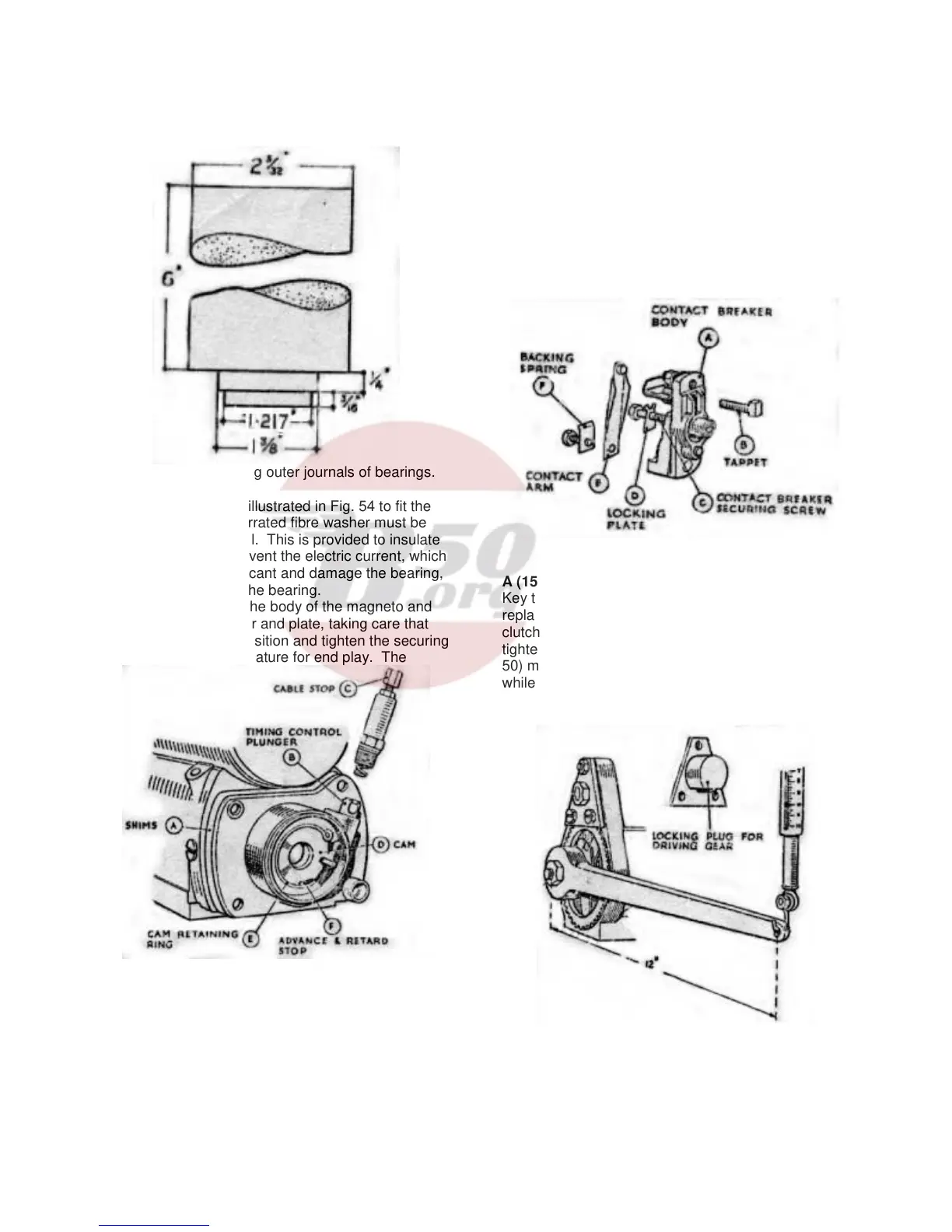

Fit the contact breaker body (A, Fig. 56) in position

on the location at the end of the shaft after making

sure that the tappet (B) is free and is located

correctly in its guides. Place the contact breaker

securing screw (C) and locking plate (D) in position,

tighten and lock by bending up the tags of the locking

plate.

Refit the spring contact arm (E) with the backing

spring (F) in its correct position i.e., with the bent

portion facing outwards. Check the contact breaker

gap and if necessary adjust to correct setting.

Fig. 56. Contact breaker assembly.

A (15) Re-assembling and Testing Slipping Clutch

Key the gear centre (A, Fig. 49) on to the spindle,

replace the driving gear (B), friction washer (C),

clutch spring (D). locking washer (E) and secure by

tightening the fixing nut (F). The U shaped jig (Fig.

50) must be used to prevent rotation of the shaft

while tightening the nut. After assembling, the setting

of the clutch must be checked. This can easily be

done by locking the driving gear and applying a

Fig. 57. Method of checking clutch setting

steady load on the driving spindle, as shown in Fig.

57. The clutch should slip with a load of 4-10 lbs.

feet, i.e., a 4-10 lb. pull measured out on a spring

balance via a spanner one foot long.

37

Loading...

Loading...