RE-ASSEMBLING THE ENGINE

The need for extreme cleanliness cannot be over-emphasised.

Parts should be thoroughly cleaned and all trace of any antirust preparations with which new parts may be

coated must be removed.

All bearing surfaces should be liberally smeared with engine oil when assembling.

FLYWHEELS

If the big end assembly is to be renewed it is as well

to check the weight of the new components

against

those which have been removed. A slight variation in

the weights is inevitable, but provided that the

discrepancy does not exceed 1 ½ oz no further

action need be taken. This tolerance should not be

exceeded since in the first instance the flywheels

have been balanced to suit the original parts, and the

balance may be adversely affected if the weight of

the new components varies considerably from that of

the original ones.

The driving side flywheel should now be fitted to the

crankpin (this is the side with the keyway) and the nut

tightened up by hand. Fit the timing side flywheel

and again tighten the crankpin nut by hand.

In order properly to tighten the crankpin nuts, the

whole flywheel assembly must be held rigidly. For

this purpose, it should be mounted in a large vice

(fitted with lead clamps) with the driving side flywheel

uppermost. If a large enough vice is not readily

available an alternative method is to fix rigidly to the

bench in a vertical position, two 1

1

/

16

” diameter

posts, the distance between their centres being 3

7

/

8

”. Midway between the posts a hole of 1” diameter

should be bored in the bench to receive the

mainshaft. The flywheel assembly is mounted on

these posts so that they pass through the holes

bored in the flywheels and the driving side flywheel

should be uppermost. Tighten the crankpin nut very

firmly, using a tubular extension to the spanner as

when dismantling, and fit the locking plate and screw.

Suitable packing under timing side “vee” block to

compensate for smaller diameter bearing.

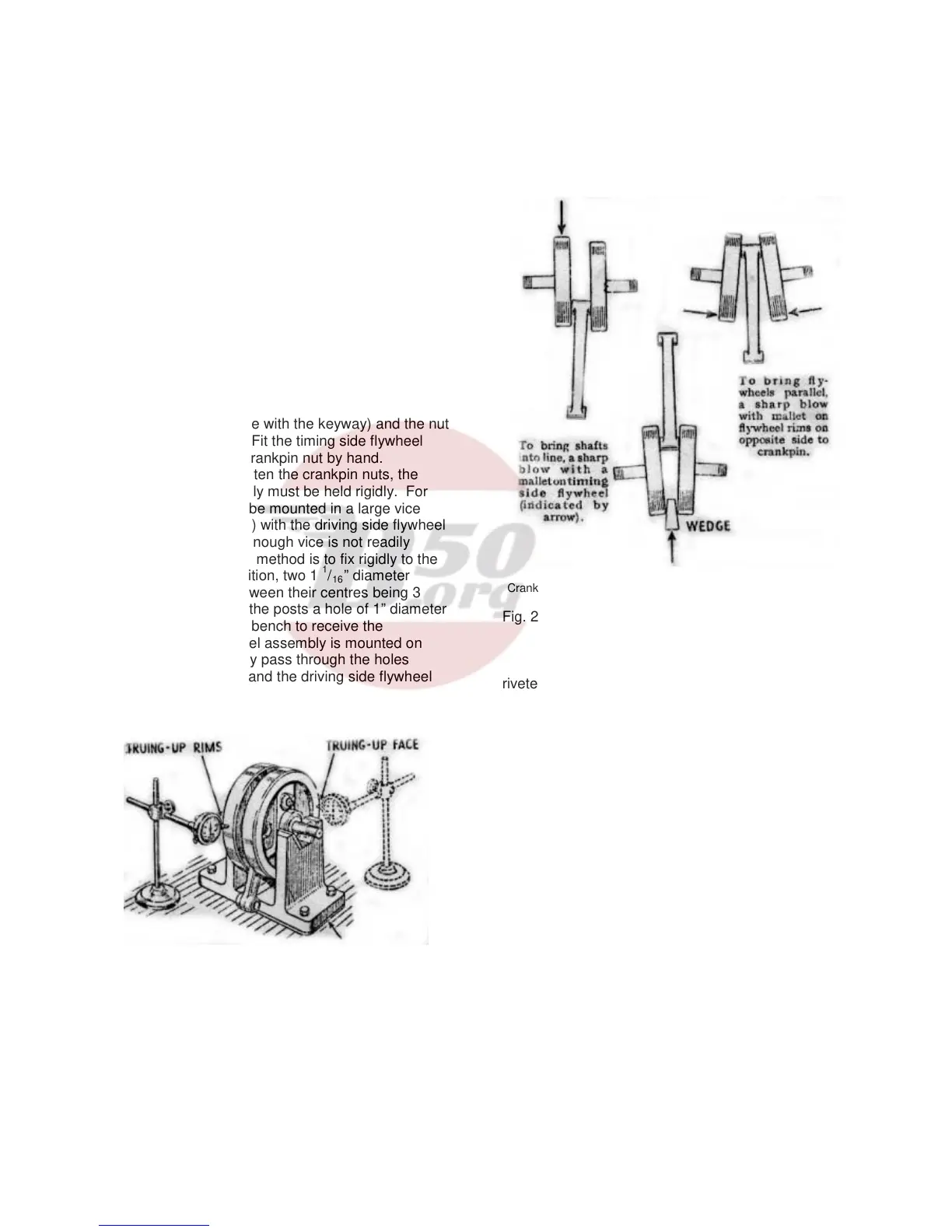

Fig. 21. Checking flywheel alignment.

Now turn the assembly over, so that the gearside

flywheel is on top and tighten the crankpin nut lightly.

The grub screw in the end of the crankpin must be

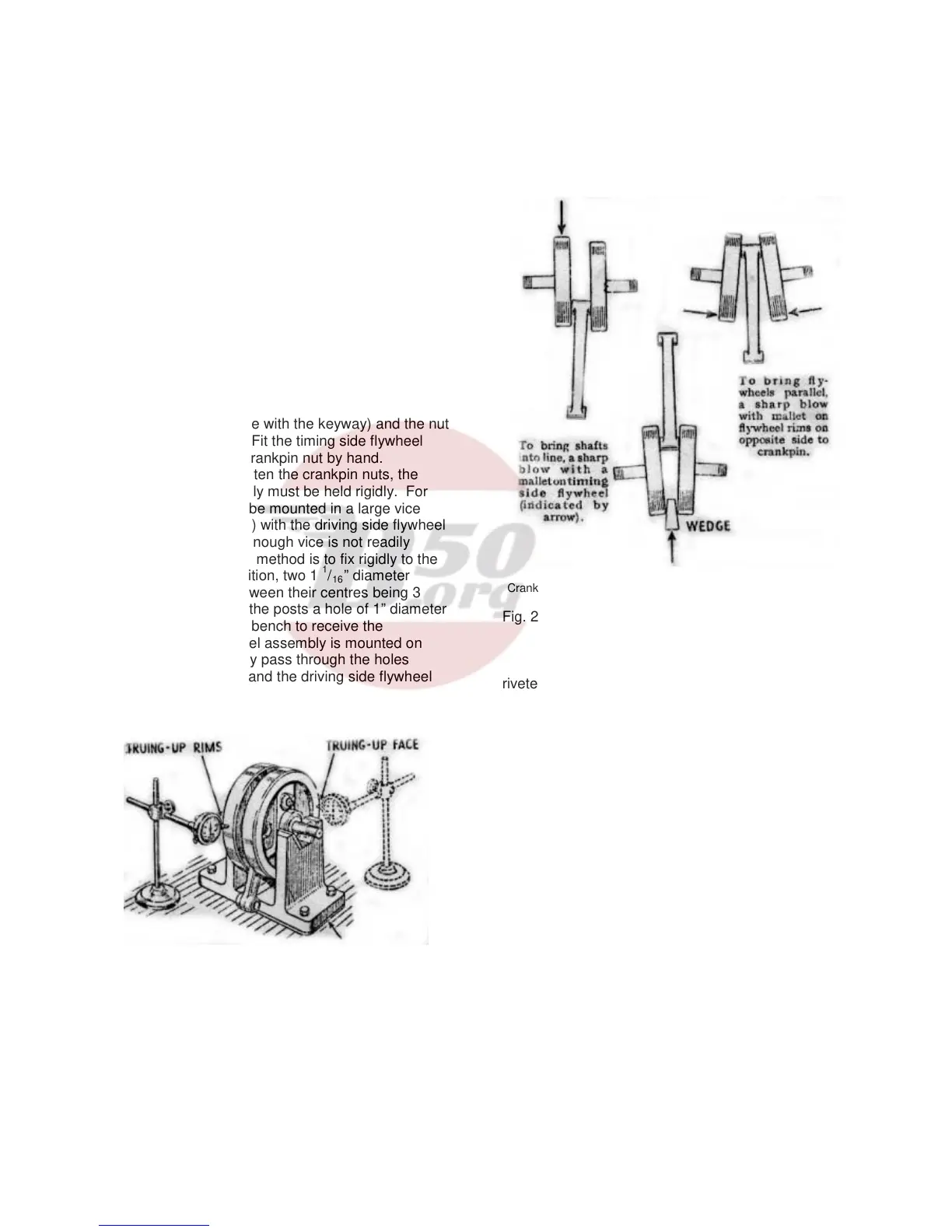

To bring flywheels parallel when sides opposite

Crankpin are converging insert wedges as shown and deal sharp

blow with mallet.

Fig. 22. Method of correcting flywheels out of

alignment. Note that above illustrations are

greatly exaggerated.

riveted over or centre-punched to prevent its

unscrewing. If it unscrews serious damage may

result to the engine. Check that the side clearance of

the connecting rod in the flywheels does not exceed

.012” and is not less than .010”.

The flywheels will now be aligned only very

approximately and further steps must be taken to

ensure that the wheels are aligned as true as

possible. Two of the actual (or similar) bearings to

be used in the engine should be fitted to the

mainshafts and the latter mounted on vee-blocks.

The flywheels must be trued up, both on faces and

rims, for which purpose a dial micrometer is

necessary (Fig. 21), and after the wheels are trued to

within at least .005” tighten the timing side crankpin

nut fully. A mallet or lead hammer applied to the

flywheels will provide a sufficiently heavy blow for

final truing, and will not harm the flywheels (Fig. 22).

The shafts must not be struck. The shafts should be

finally trued to within .002” maximum.

16

Loading...

Loading...