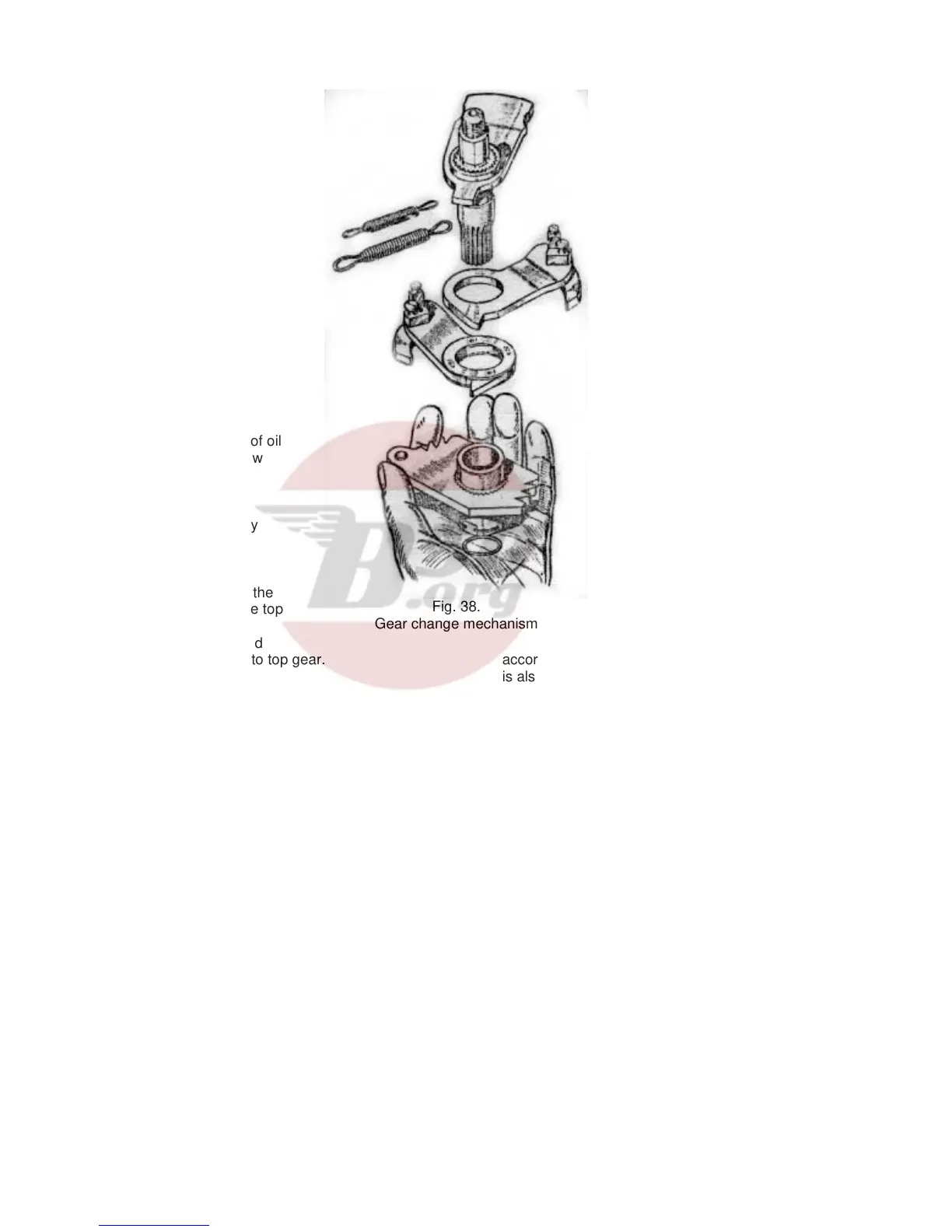

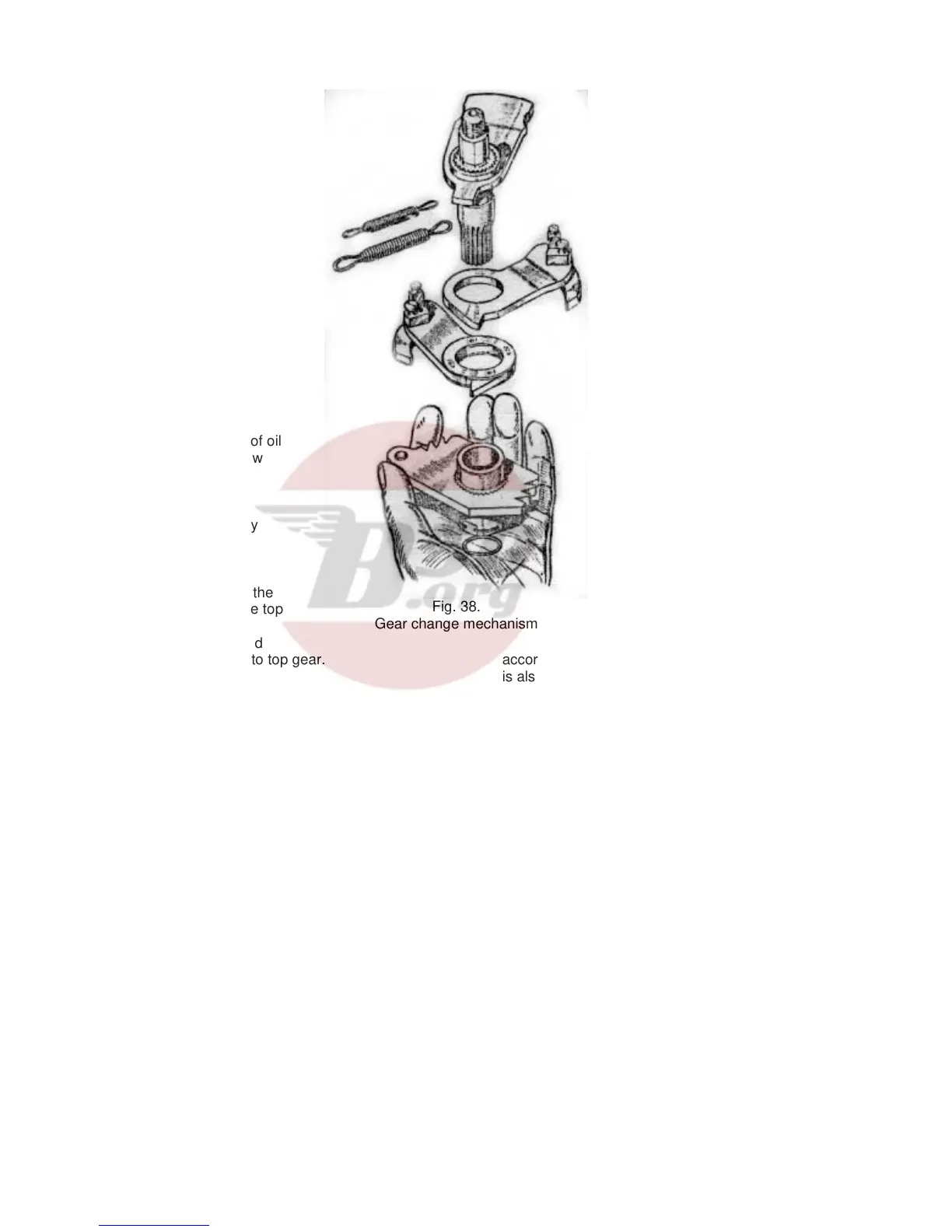

Fig. 38.

Gear change mechanism

Before the re-assembly is

carried out a stage further,

loosely replace the

gearchange pedal and

check the operation of all

gears by inspection through

the cover. It will, of course,

be necessary to move the

gearbox sprocket by hand

when endeavouring to

engage the gears.

When all is found to be

correct, set gears in top gear

position again, and remove

the gearchange pedal. The

clutch push rod is next to be

replaced, and with this in

position the small felt

washer must be added.

This washer is important

since its function is to

prevent any possibility of oil

passing along the hollow

mainshaft, to the clutch

plates.

Finally, put back the

gearbox cover, carefully

tighten all screws, and

carefully replace the

kickstarter crank and

gearchange pedal. As the

gearbox is still set in the top

gear position when the

indicator disc is replaced

this also should be set to top gear.

REPLACEMENT OF THE GEARBOX

The replacement of the gearbox

should not present any difficulties.

When the box is in position and

the fixing bolts are about to be

tightened up, make sure that the

flats just below the bolt heads

register properly in the slots

machined in the yoke plates.

Also, on the rear bolt, an adjuster

is provided for tensioning the

primary chain; this must be in

position and the chain tension

adjusted before the gearbox bolts

are finally tightened. The latter

must be really tight after the

adjustment is made. There should

be about ½ “ total play in the chain

(see “Front Chain”, page 20).

Replace the oil tank pressure

release pipe together with the

clutch cable and its adjuster.

The inner half of the primary

chaincase may now be fitted,

followed by the cush drive, chain

and clutch, together with it’s

pressure plate and cover. Finally

refit the outer half of the chaincase

and then the footrest.

The refitting of the clutch and

primary chaincase is described in

the chapter “Re-assembly of the

Clutch” on page 22. The clutch

adjustment may require setting

and this should be carried out in

accordance with the instructions given on Page 20. It

is also possible that the rear chain will require re-

tensioning and this may be done by movement of the

rear wheel (see page 20).

SPECIAL INSTRUCTIONS FOR THE

CLEANING AND LUBRICATION OF HUBS

Remove bearing cone assemblies from hub as

described in the next section, page 27. Wash

bearings, cones, spindle and inside of hub in paraffin

and dry thoroughly. Do not use compressed air.

Inspect bearing races and replace if damaged.

Replace grease seals if necessary. Lubricate

bearings with grease No. 2 with a wheel-bearing

packer, or by hand, kneading lubricant into all spaces

in the bearing roller cage. Use extreme care to

protect the bearings from dirt and dust.

Pack inside of hub shell with grease No 2.

The lubricant in the hub and bearings is sufficient to

provide lubrication until the next service period.

Reassemble and adjust bearings in accordance with

the instructions given in the next section.

26

Loading...

Loading...