ENGINE DISMANTLING for DECARBONISING

When decarbonising, it is not necessary or desirable

to dismantle the cylinder barrel, unless it is suspected

that the valves, pistons or its rings are the cause of

some trouble. It is sufficient to remove the cylinder

head and gasket thus exposing the piston and

valves.

REMOVING CYLINDER HEAD

To detach cylinder head, disconnect sparking plug

lead, remove steady strap and the 10 cylinder head

bolts. Head can then be lifted off.

Rotate the engine until the piston is at the top of its

stroke and scrape it with an old penknife, taking great

care not to damage the piston crown. Then clean the

cylinder head and replace, tightening the bolts in the

order shown in Fig. 24.

If the valve seats are suspected of gas leakage, due

to insufficient tappet clearances or other causes

these should be remedied. It is possible to grind in

the valves in position, but it is preferable to remove

the barrel from the crankcase so that the work may

be carried out on the bench, and at the same time

the piston and rings inspected.

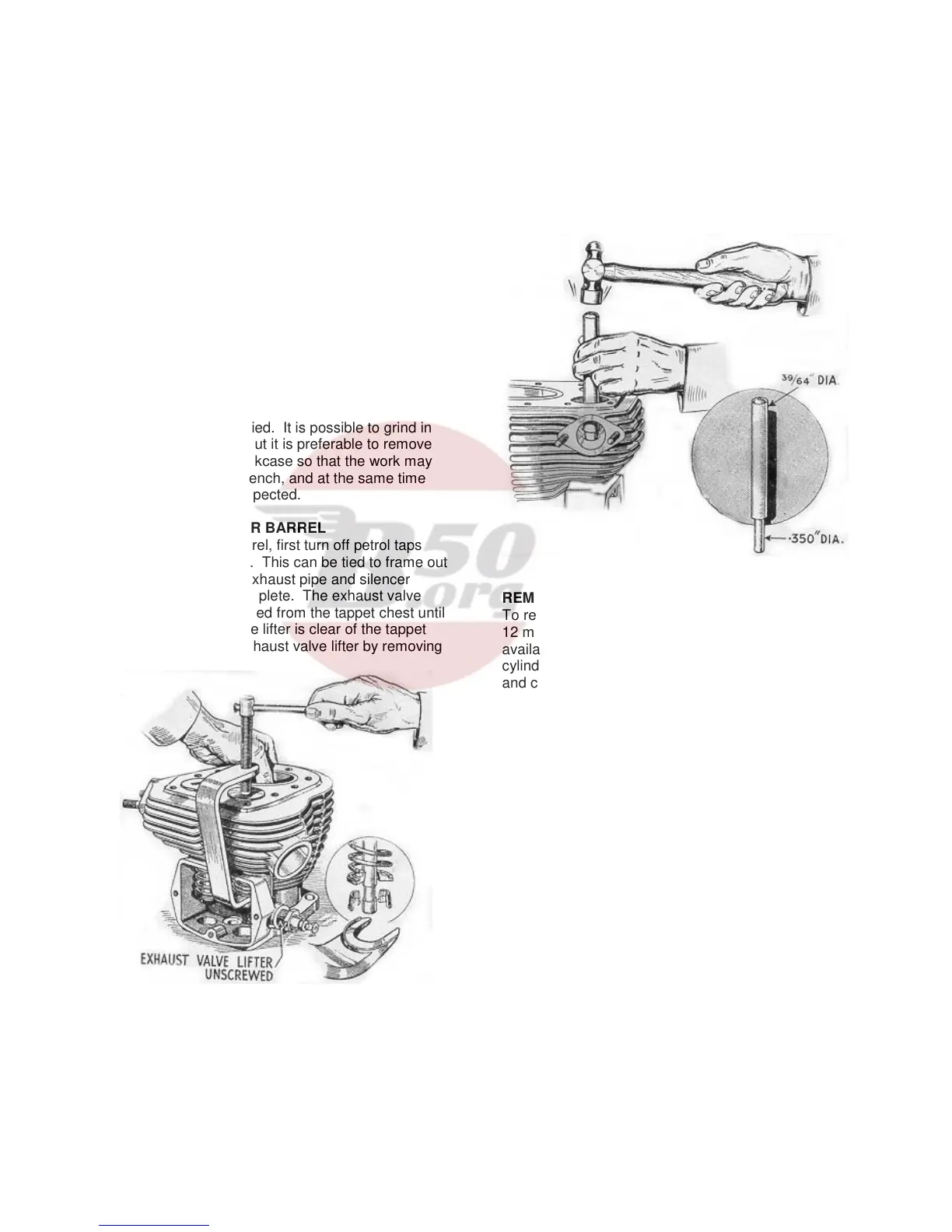

REMOVING CYLINDER BARREL

To remove cylinder barrel, first turn off petrol taps

and detach carburetter. This can be tied to frame out

of the way. Next, the exhaust pipe and silencer

should be removed complete. The exhaust valve

lifter should be unscrewed from the tappet chest until

the eccentric peg on the lifter is clear of the tappet

head. Uncouple the exhaust valve lifter by removing

Fig. 12. B.S.A. Valve removing tool.

the pin at the lever end. Now remove the five

cylinder base nuts (four outside and one inside

tappet chest), and cylinder barrel can be lifted off.

When removing the cylinder barrel, the simplest way

is to lift it up and tilt it forwards into the front angle of

the frame. The piston should be steadied as it

emerges from the barrel to prevent possible damage.

Cover the crankcase mouth with rag to prevent dust

and grit falling in.

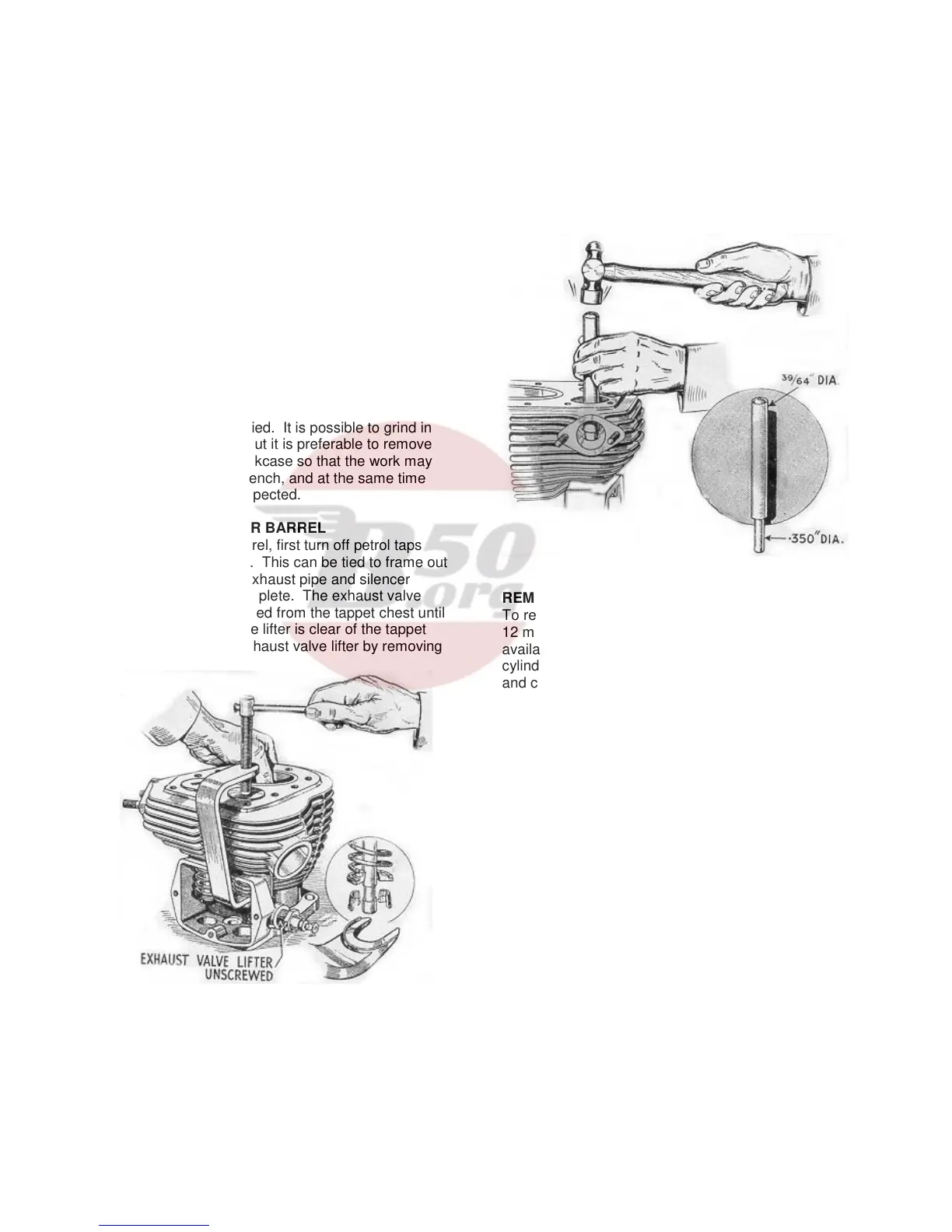

Fig. 13. Inserting valve guides

REMOVING THE VALVES

To remove the valves an extractor as shown in Fig.

12 may be used. If the proper extractor is not

available, the valves may be removed by laying the

cylinder barrel on a bench (valve heads downwards)

and compressing the valve springs with the aid of a

piece of tube (suitably slotted), while an assistant

removes the cotters. Clean all carbon from the ports

and check valve guides for wear.

FITTING NEW VALVE GUIDES

If new guides are to be fitted, the old ones may be

extracted (from below) by means of a simple punch

(consisting of a bar of steel of not more than 5/8”

diameter – Fig. 13). The new guides can be driven in

from the top with the same punch and it is important

that the dimensions from the top of the guide to the

cylinder head joint (as shown in Fig. 14) should be

carefully observed. After the new guides have been

inserted, the valve seats should be re-cut with a pilot

cutter to ensure concentricity of seats and stems (see

Fig. 14). Note that the exhaust valve guide only has

it’s upper end counterbored.

GRINDING IN VALVES

If the old valves are to be retained, they should only

be ground in if the seating shows slight pitting. If

badly pitted, they should be refaced, otherwise

excessive grinding

11

Loading...

Loading...