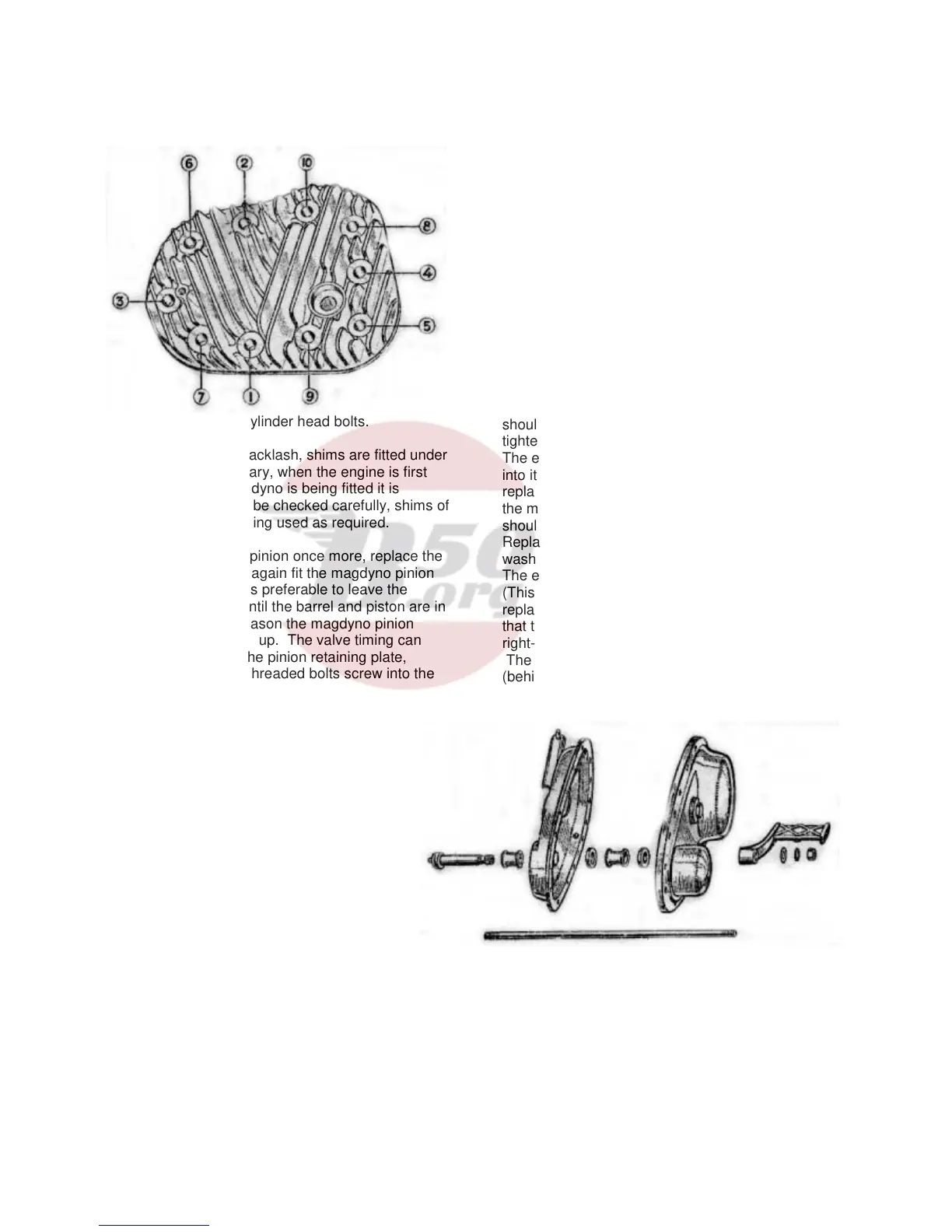

Fig. 25. Assembly of chaincase and footrest.

not be driven on very firmly but just tightly enough to

prevent slip. Check the backlash between this pinion

and the idler. If excessive, the gears will be noisy; if

insufficient, a whining noise will result.

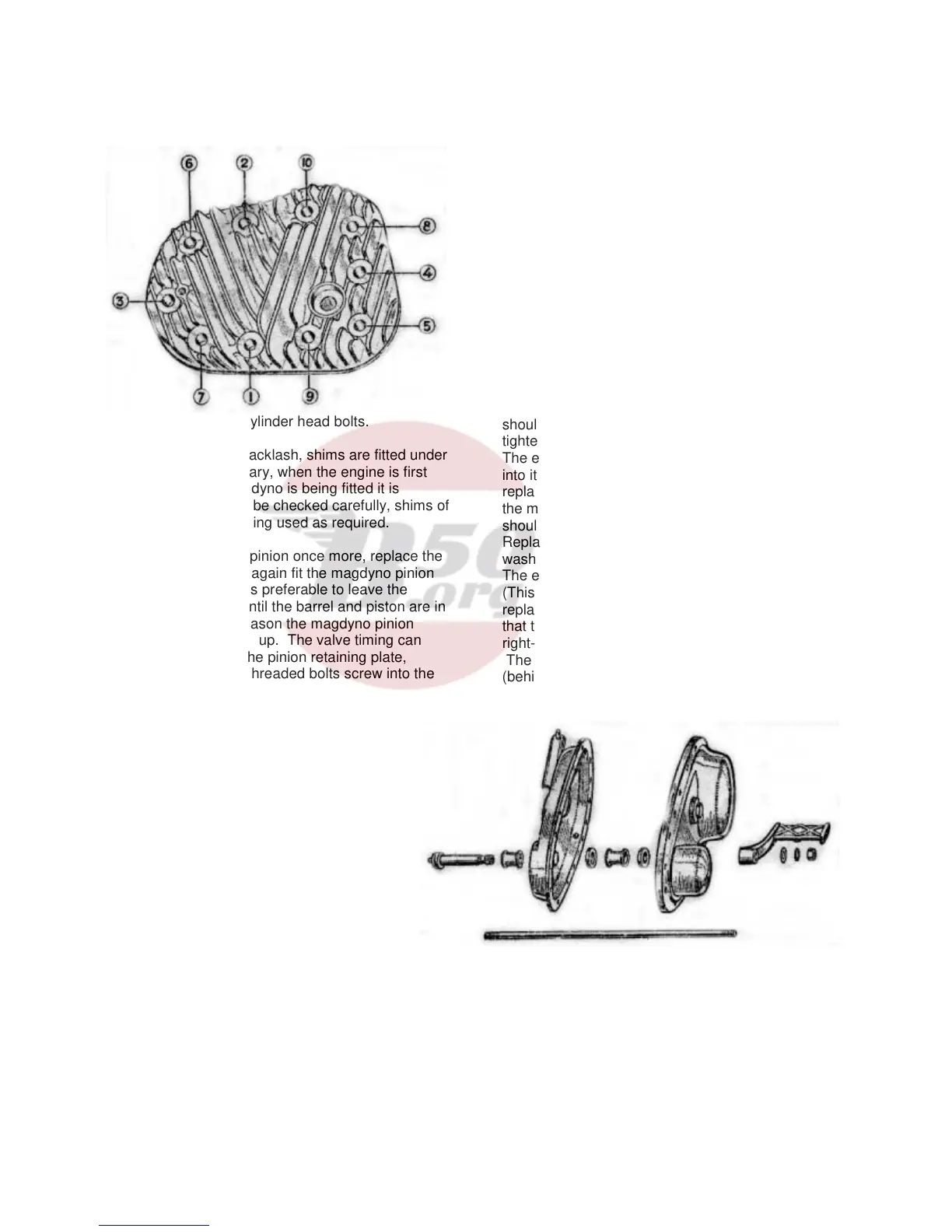

Fig. 24. Cylinder head bolts.

In order to adjust the backlash, shims are fitted under

the magdyno if necessary, when the engine is first

built. If a different magdyno is being fitted it is

essential this backlash be checked carefully, shims of

a different thickness being used as required.

Remove the magdyno pinion once more, replace the

oil sealing washer and again fit the magdyno pinion

loosely in position. It is preferable to leave the

setting of the ignition until the barrel and piston are in

position, and for this reason the magdyno pinion

should not be tightened up. The valve timing can

now be set. Replace the pinion retaining plate,

noting that the coarse threaded bolts screw into the

crankcase bosses and then fit the lockwasher and

nut on the engine mainshaft. Play between the

pinions and the retaining plate should be

.002”/.003”.

ASSEMBLY FROM THIS POINT WILL BE

THE SAME AS AFTER

DECARBONISING.

CYLINDER AND PISTON

The gap between the ends of the rings

should be checked with the ring in the

cylinder. If the gap is excessive new rings

should be fitted with gaps of .008”/.012”.

Replace the piston and gudgeon pin on the

connecting rod and if the original piston is

used make sure that it is the correct way

round (see Page 12). Do not omit the

gudgeon pin circlips and verify that they are properly

fitted.

Set the tappets on their lowest position, fit the paper

washer on the cylinder base and replace the cylinder

barrel on the crankcase. The piston rings may be

compressed quite easily by hand while the barrel is

being replaced.

Tighten the barrel down, not forgetting one nut is

inside the tappet chest. The tappet clearances

should be set very carefully as described on pages 8

and 9.

Next set the ignition timing as described on Page 9.

Note that as the magneto cable is disconnected the

cam will be in the “full retard” position and it must be

held in the “full advance” position.

The resetting of magneto timing will not apply after

decarbonising as there is no necessity to disturb the

timing to remove the cylinder head and barrel.

Replace the timing cover after lightly smearing both

sides of its paper washer with jointing compound,

taking care that the oil hole (Fig. 17) is not

obscured. (This does not apply after

decarbonising). Bolt the cylinder head and gasket in

position, but if the latter shows signs of leakage from

previous use (indicated by black patches) a new one

should be fitted. The cylinder head bolts must be

tightened down in the order shown in Fig. 24.

The exhaust valve lifter body may now be screwed

into its original position. Before the sparking plug is

replaced it should be dismantled and cleaned, or if

the machine has covered a large mileage a new plug

should be used

Replace the tappet cover and lightly smear the

washer with jointing compound before fitting.

The engine is now ready for bolting into the frame

(This does not apply after decarbonising), and after

replacement check that the bolts are really tight, and

that the gearbox bolts have not been forgotten. Refit

right-hand footrest assembly pushing rod fully home.

The near-side footrest sleeve and distance piece

(behind chaincase) should now be placed in position.

Then refit the inner half of the chaincase (first

checking that oil-seal washer is in good condition)

and when the bolts holding it to the crankcase have

been finally tightened, wire them together with a fresh

piece of wire for locking purposes.

The engine shaft cush drive can be replaced by

hand, without the need for special tools to compress

18

Loading...

Loading...