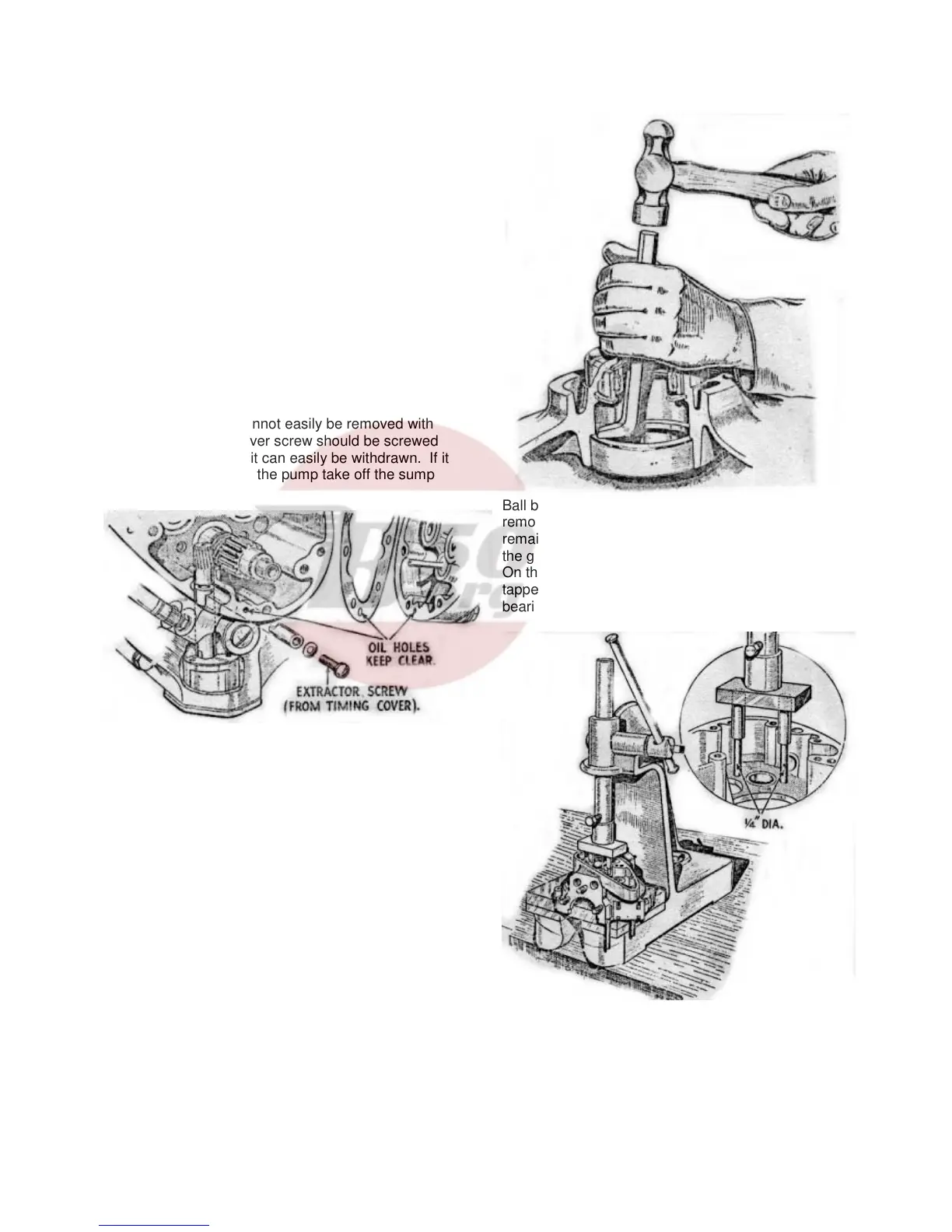

Fig. 17 Oil pump spindle locking plunger

The engine shaft nut should be removed and the

plate holding the timing gears in position is detached

by removal of the six fixing bolts, three of which

screw into the crankcase casting and have coarse

threads, while the remaining three screw into the

pinion spindles and have fine threads. All the pinions

can now be withdrawn with the exception of the

engine shaft pinion which may require an extractor.

The latter is shown in Fig. 16, and in order to prevent

damage to the engine mainshaft, a flat headed pin of

suitable dimensions should be inserted in the oil hole,

in the manner illustrated. If the pinions are re-bushed

they should be reamed out to .6255”/.6250” for the

cams and .7505”/.7495” for the idler pinion. The

correct size for the outrigger bearing in the timing

gear plate is .815”/.814”.

Before the oil pump spindle is released it is first

necessary to remove the locking plunger which is

exposed after removal of the timing cover (Fig. 17).

Take care not to lose the loose washer covering the

plunger. If the latter cannot easily be removed with

the fingers, a timing cover screw should be screwed

into the plunger, when it can easily be withdrawn. If it

is necessary to remove the pump take off the sump

cover plate, together with the filter and joint washers,

and remove the two bolts holding the pump in

position, thus releasing the pump. These two bolts

are the ones with spring washers under the heads;

the other two bolts hold the pump parts together and

should not be disturbed unless it is strongly

suspected that the pump is giving trouble.

The crankcase is now ready for “splitting”. Release

all the bolts around the crankcase joint face (the

magneto strap hinge pins also act as bolts and the

nut on these must be removed) and draw each half of

the crankcase off the engine mainshaft. Where

single lipped roller bearings have been used in the

engine, the outer race will remain in the crankcase

and if necessary can be pressed out later. It should

be remembered that the outside bearing on the drive

side has its outer race retained in the crankcase by

means of a spring ring which must be removed

before extracting the race.

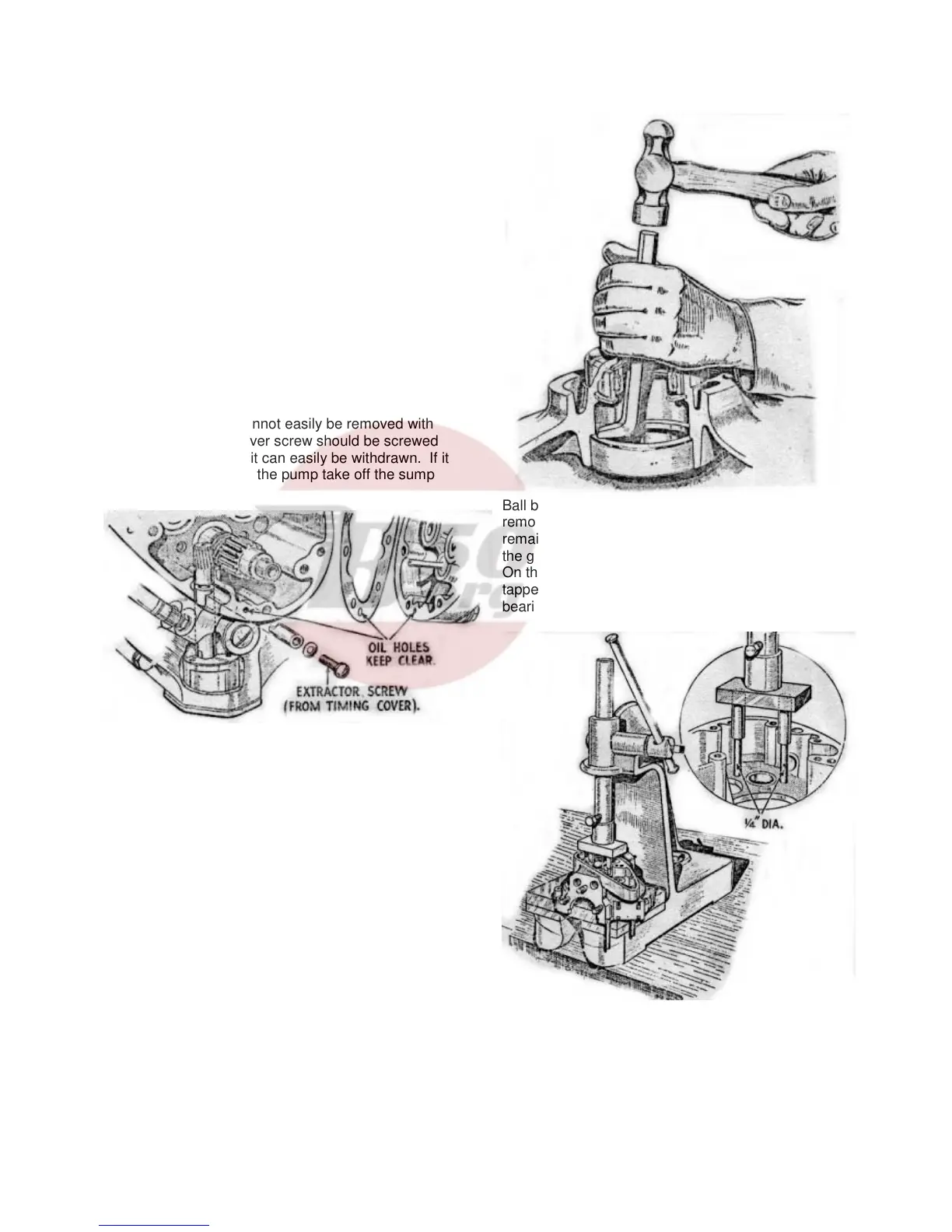

Ball bearings will usually be left on the shafts after

removal of the crankcase halves, but should they

remain in the crankcase, they may be pressed out of

the gearside in an arbor press as shown in Fig. 19.

On the drive side the inner bearing must first be

tapped out with a punch, projecting through the outer

bearing and, working all round the

Fig. 19. Ballrace extraction (gearside)

14

Loading...

Loading...