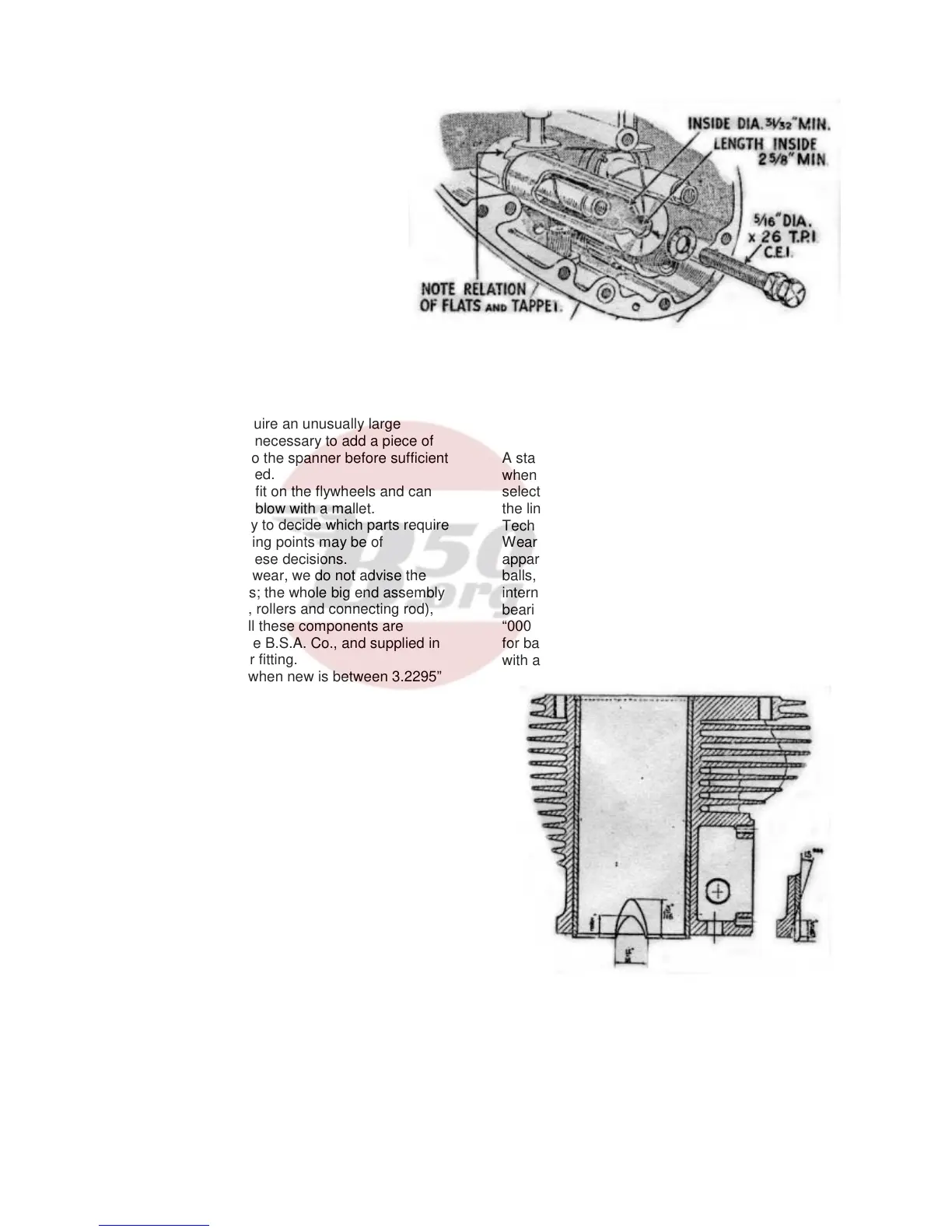

Fig. 20 Cam pinion spindle extractor.

Bearing to give even extraction (Fig. 18).

These operations will be considerably

helped if the crankcase is first warmed, the

most suitable method being by dipping in

boiling water.

If it is desired to remove the cam pinion

spindles, they can easily be taken out by

means of an extractor (Fig. 20). Do not

remove these spindles unless

absolutely necessary. If the tappets

require renewal, then the cam spindles and

tappet guides must be withdrawn so that

the tappets can be drawn out downwards

into the timing case. The exhaust tappet

requires special treatment, and should not

be replaced by an inlet tappet. The tappet

guides unscrew upwards out of the

crankcase.

The final item is the flywheel assembly. Remove the

locking plates holding the crankpin nuts and take off

the latter. They will require an unusually large

leverage and it may be necessary to add a piece of

tubing of suitable size to the spanner before sufficient

purchase can be obtained.

The crankpin is a taper fit on the flywheels and can

be released by a sharp blow with a mallet.

It is now only necessary to decide which parts require

renewal, and the following points may be of

assistance in making these decisions.

In the event of big-end wear, we do not advise the

fitting of oversize rollers; the whole big end assembly

(consisting of crankpin, rollers and connecting rod),

should be changed. All these components are

carefully matched by the B.S.A. Co., and supplied in

complete sets ready for fitting.

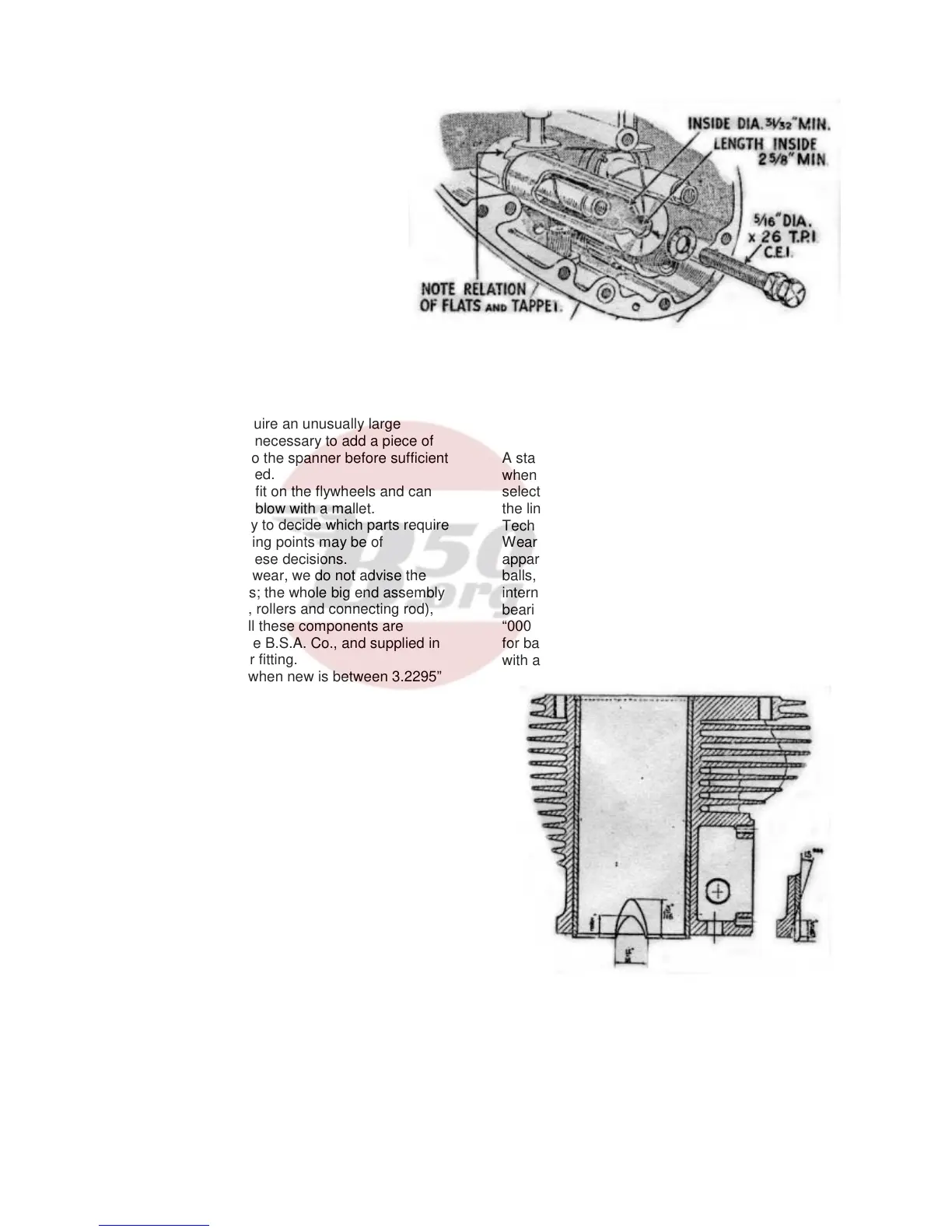

The bore of a cylinder when new is between 3.2295”

and 3.2280” (82mm) and when the bore (measured

at right angles to the gudgeon pin) shows wear to the

extent of .010” or more, the liner should then be

rebored to ½ mm. oversize (3.2487” – 3.2477”) and a

½ mm oversize piston fitted. Subsequently, the liner

may again be rebored, to 1 mm. oversize (3.2684” –

3.2674”) and a 1 mm. oversize piston fitted.

When wear develops after the second rebore, it is

necessary to fit a new cylinder liner. A suitable screw

or hydraulic press giving a pressure of between 5

and 7 tons is necessary – first to press out the old

liner (which must be pressed out from the base of the

cylinder) and then to insert the new liner, which is

pressed in from the top of the cylinder. Owing to the

possibility of the liner “closing-in” during the fitting

process, it must be ground to a finished diameter of

3.229” – 3.228” when in position.

It is also necessary to grind two scoops at the skirt of

the liner at right angles to the gudgeon pin to provide

clearance for the connecting rod (see illustration

below).

A standard piston and rings must of course be fitted

when a new liner is used. The piston should be

selected so that the clearances between the skirt and

the liner fall within the prescribed limits given in

Technical Data (page 2).

Wear in the mainshaft bearings will be readily

apparent and bearings showing signs of damaged

balls, rollers or tracks should be replaced. Special

internal clearances are specified for mainshaft

bearings used on B.S.A. motor cycles, and these are

“000 clearance” for roller bearings and “00 clearance”

for ball bearings. It is not advisable to fit bearings

with any other clearance.

Two scoops diametrically opposite, ground after liner

is pressed in.

15

Loading...

Loading...