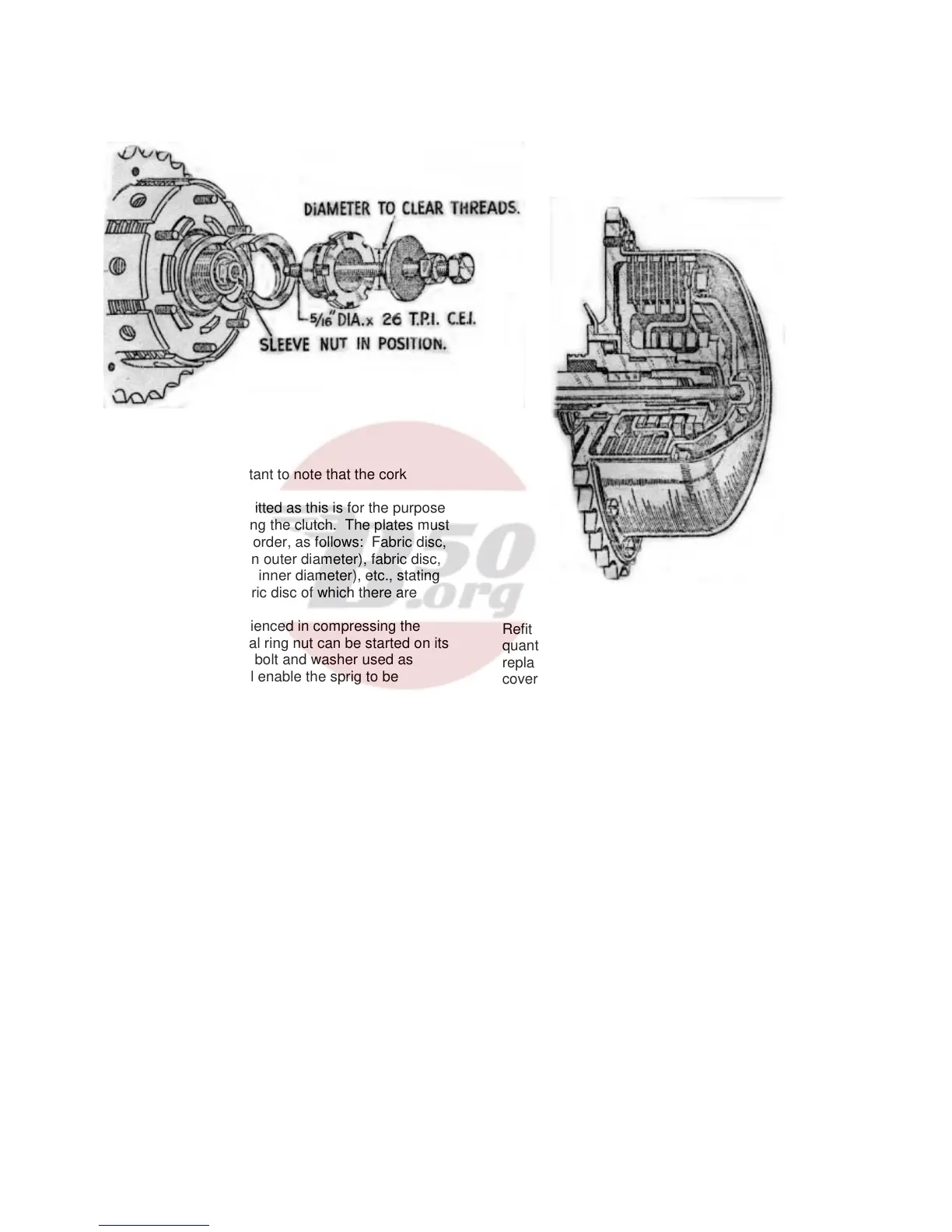

Fig. 31. Clutch assembly tool.

RE-ASSEMBLY OF THE CLUTCH

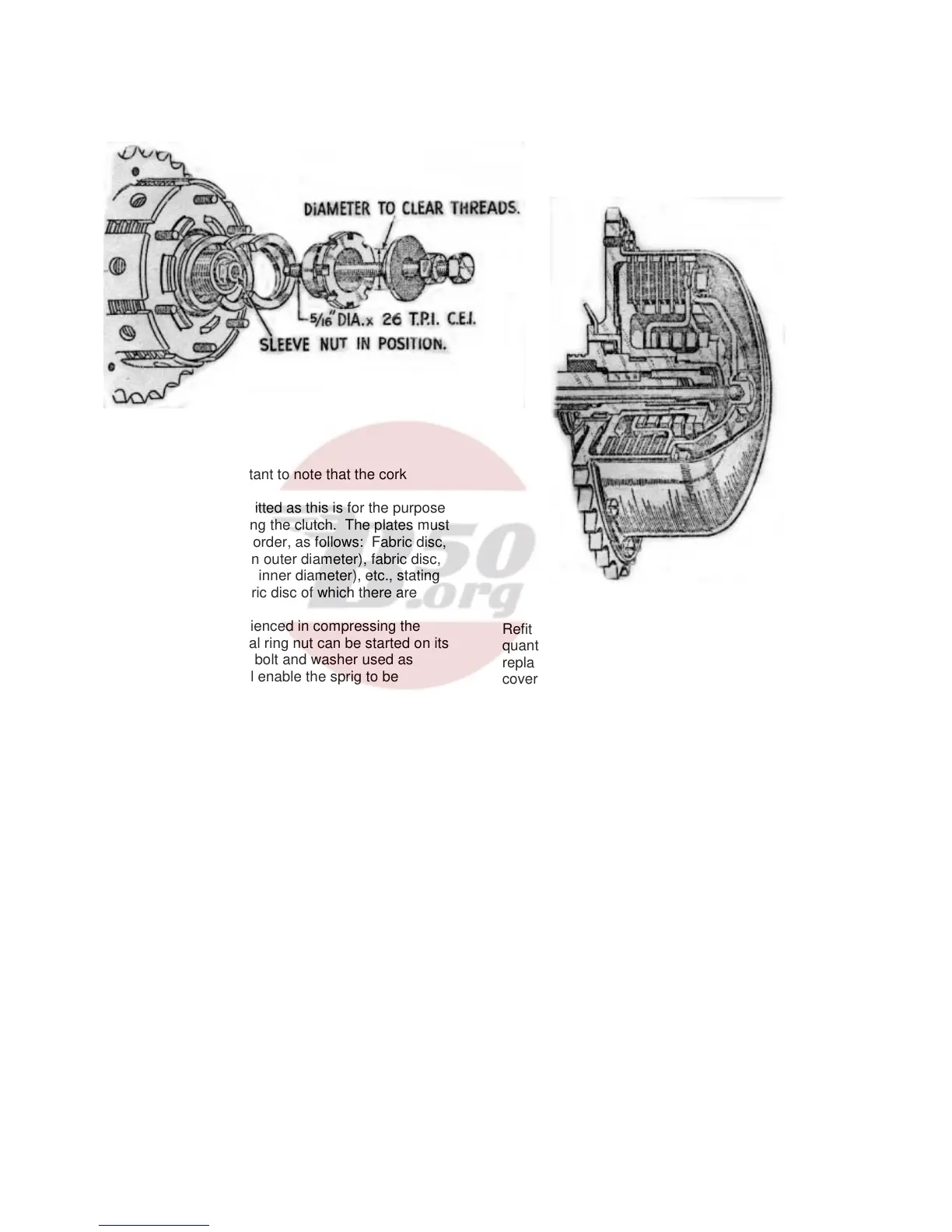

The clutch is of straight-forward construction and a

study of Fig. 32 will show how the parts are

assembled. It is important to note that the cork

washer must not be omitted as this is for the purpose

of preventing oil reaching the clutch. The plates must

be fitted in their proper order, as follows: Fabric disc,

driven plate (tongues on outer diameter), fabric disc,

driving late (tongues on inner diameter), etc., stating

and finishing with a fabric disc of which there are

eight.

Difficulty may be experienced in compressing the

spring before the central ring nut can be started on its

threads, and a suitable bolt and washer used as

illustrated in Fig. 31 will enable the sprig to be

compressed sufficiently for the ring nut to be screwed

home.

No adjustment is provided for altering he tension of

the ring and the ring must be screwed up tight. After

carefully centralising sliding plate (in ear half of

chaincase) with gearbox mainshaft, refit

clutch assembly to mainshaft after cork

washer and key have been placed in position.

Screw home and well tighten sleeve nut.

Fig. 32. Section through clutch.

Refit clutch actuating cap (first smearing small

quantity of grease on ball in centre) and finally

replace clutch cover. When replacing the clutch

cover verify that the paper washer is in position and it

should be lightly smeared with jointing compound

before assembly, to ensure an oil-tight joint.

22

Loading...

Loading...