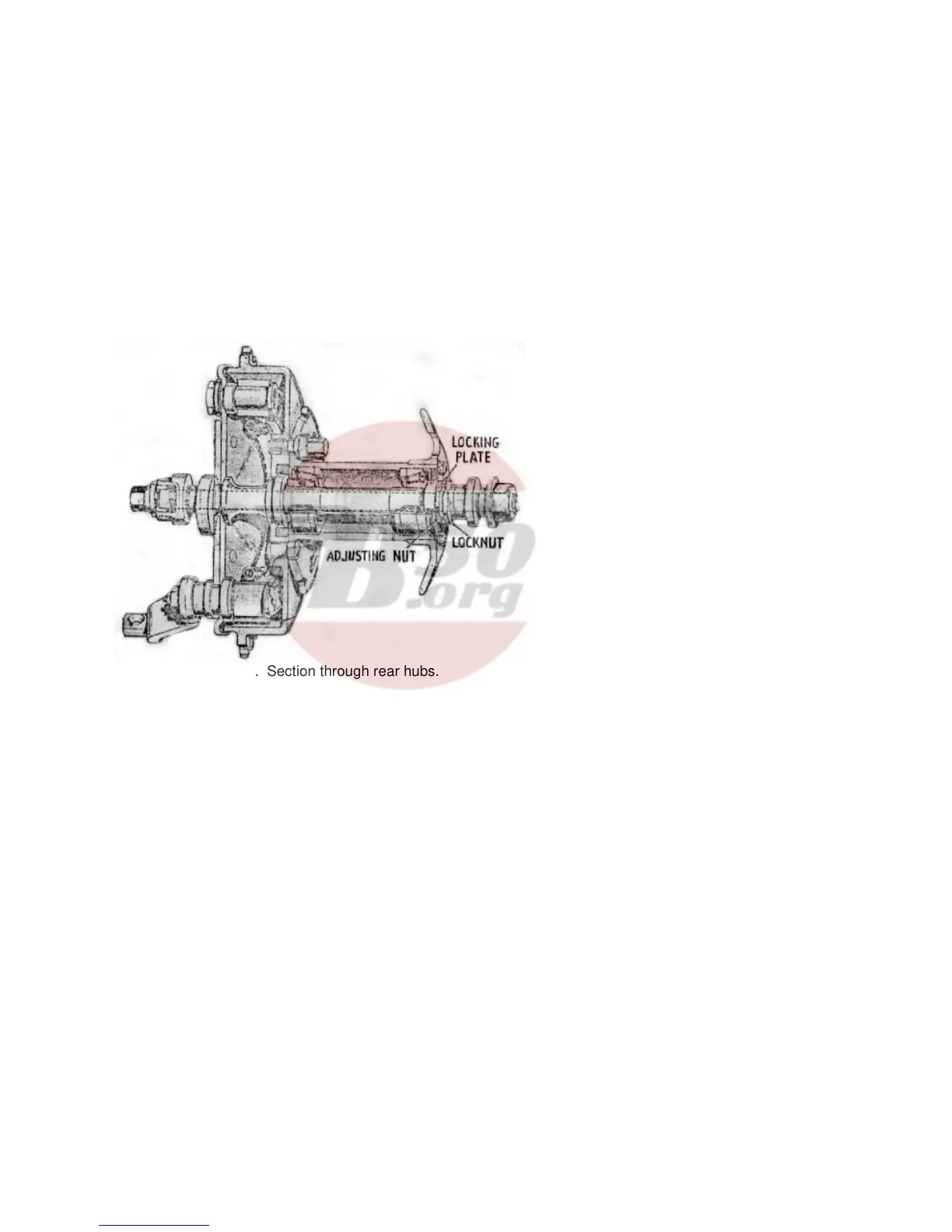

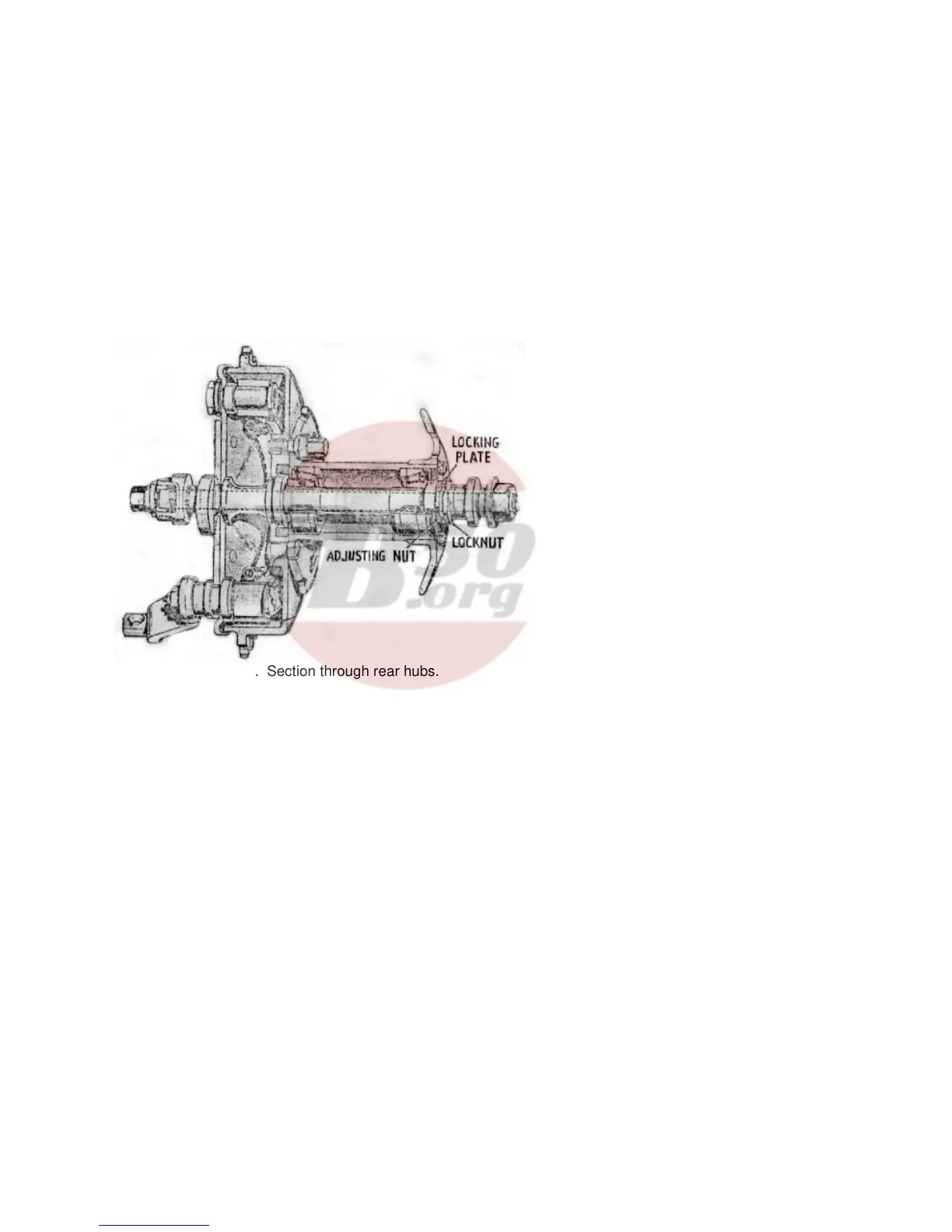

Fig. 39. Section through rear hubs.

ADJUSTMENT, DISMANTLING AND RE-ASSEMBLY

OF HUBS AND BRAKES

REAR HUB (Fig. 39)

The rear wheel is of the quickly detachable type and

the taper roller bearings are contained in the wheel

hub. To remove the rear wheel it is only necessary

to undo the three retaining bolts and withdraw the

spindle from the nearside. The latter is released after

the nut on the offside end is removed. The spindle

does not unscrew; it is a push fit in the hub.

Should it be too tight to be removed by hand, it may

be tapped out from the offside. Remove the distance

piece o the right-hand side and withdraw the hub to

the right from the driving studs. The wheel itself is

now free and can be taken out rearwards after the

detachable portion of the mudguard is removed.

Uncouple the rear chain, the brake cover plate (at its

junction with the torque stay) and the brake rod. The

whole brake drum assembly can now be taken off,

after removal of the locknut on the nearside of the

spindle.

To remove the bearings it is only necessary to take

off the locknut and adjusting nut on the right-hand

side of the hub, when the bearing sleeve may be

drawn out from the opposite side. The outer races of

the bearings are lightly pressed into the hub and will

tap out easily after removal of the dust-cap.

Thoroughly clean the bearings and examine

carefully. If they have been run in too tight a

condition, flats may have been worn on the rollers

and a track formed in the outer race. Check also that

the bearing sleeve and hub spindle have not been

distorted through misuse. If necessary, renew.

The brake drum cover plate can be withdrawn from

the brake drum and it will be seen to carry the brake

shoes together with their fulcrum pin and operating

cam. It is unlikely that these will require attention

although the latter should be checked for freedom of

movement and dismantled and greased if necessary.

To remove the brake shoes, lay drum cover plate flat

on bench (shoes uppermost) and lever shoes

upwards. They can then be drawn over and free of

cam and fulcrum pin. To replace, attach springs and

reverse method of removal. If the cam pads show

excessive wear, new shoes should be fitted,

otherwise if only the brake linings are worn these

alone need be replaced.

If examination of the brake drum shows that the

sprocket teeth have become hook shaped and the

braking drum scored, a new drum must be fitted.

The drum must not be machined to produce a

new braking surface. To do so is only a temporary

cure and further attention would be required

later.

When new linings, or new shoes have been

fitted, the brakes must be centralised after

refitting the wheel. To do this, replace the

brake cover plate, complete with shoes,

fulcrum pin and cam, in the brake drum.

Slacken the fulcrum pin nut, and turn the

cam so as to open the brake shoes in the

normal manner when the fulcrum pin will

move in it’s slot until both shoes are

pressing equally on to the drum. Tighten

the fulcrum pin nut firmly and release the

brake.

RE-ASSEMBLY

After fitting new bearings and bearing

sleeve, together with the adjusting nut, in

position, make certain that there is a trace of

play in the bearings. If they are locked up

so that no play is apparent, rapid wear will

be caused. The adjustment should be such

that the side play at the wheel rim is not more than

1

/

64

Withdraw the wheel spindle and replace the wheel in

position. The wheel bolts must be screwed up

tight and must be kept dead tight at all times.

Slackness will result in elongation of the stud and

dowel holes in the hub flange, necessitating

replacement. The spring washers fitted with these

three bolts have been replaced (commencing with

frame No. WDM20/82773) by chamfered bolt heads

and corresponding spherical seatings in the hub.

Method of tightening is to turn wheel until one of the

three bolts can be seen between mudguard upright

and saddle to hub backstay. Insert bar type box

spanner 69-9038 through hole in hub and engage

head of bolt. Place box spanner 66-9067 over

squared shank of first spanner and tighten bolt as

necessary. A full half turn is possible before

spanners need to be

“ after the locking plate has been replaced and

locknut screwed up tight.

Replace the brake assembly in position and couple

up the rear chain, cover plate and brake rod. Verify

that the brake cam is against its stop and adjust the

chain for tension (see page 20). For this latter

operation, the wheel spindle must be replaced

(without the hub being in position)

Loading...

Loading...