REMOVAL AND DISMANTLING OF FRONT

FORKS AND STEERING HEAD

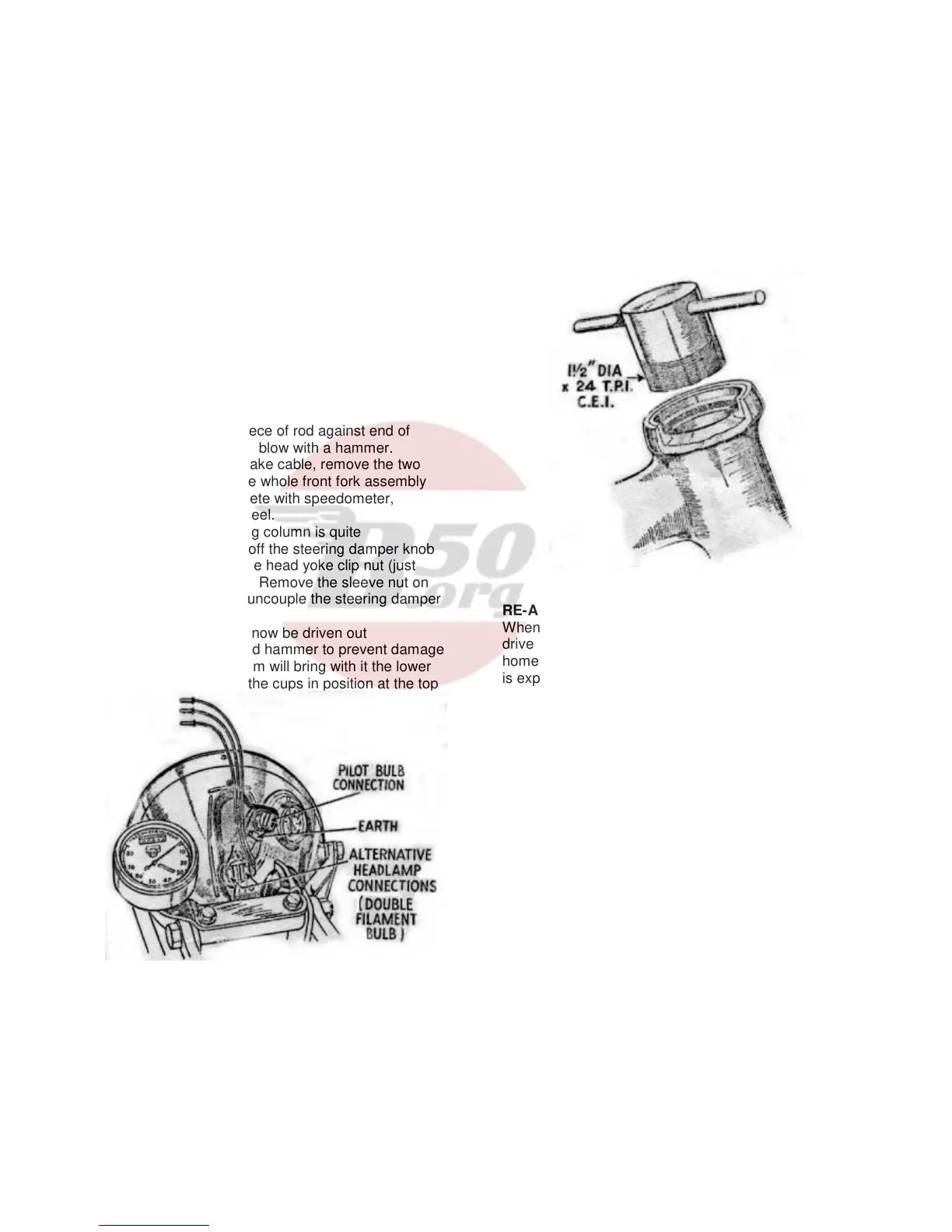

There is no necessity to disturb the electrical system

as a whole, when removing the forks. The

instrument panel on the back of the headlamp is

retained by three screws, and if these are removed,

the panel is released and the wiring can be

withdrawn through the aperture after releasing the

four connections (see Fig. 41). Place a box under

the engine so that the front wheel is clear of the

ground.

Remove the nut from the fork spring top scroll, then

remove both top fork links and prise scroll

downwards until the bolt is free from the headlug.

Headlamp wiring should now be drawn out at the

side of the forks.

To take off the fork spring it is only necessary to

unwind the spring from its bottom scroll. If difficulty is

experienced place a piece of rod against end of

spring and give a sharp blow with a hammer.

Disconnect the front brake cable, remove the two

lower fork links, and the whole front fork assembly

can be taken off complete with speedometer,

headlamp and front wheel.

Dismantling the steering column is quite

straightforward. Take off the steering damper knob

(if fitted) and slacken the head yoke clip nut (just

below the handlebars). Remove the sleeve nut on

top of the column and uncouple the steering damper

plates at the frame lug.

The steering stem can now be driven out

(downwards) with a lead hammer to prevent damage

to the threads. The stem will bring with it the lower

ballrace cone, leaving the cups in position at the top

Fig. 41. Headlamp connections.

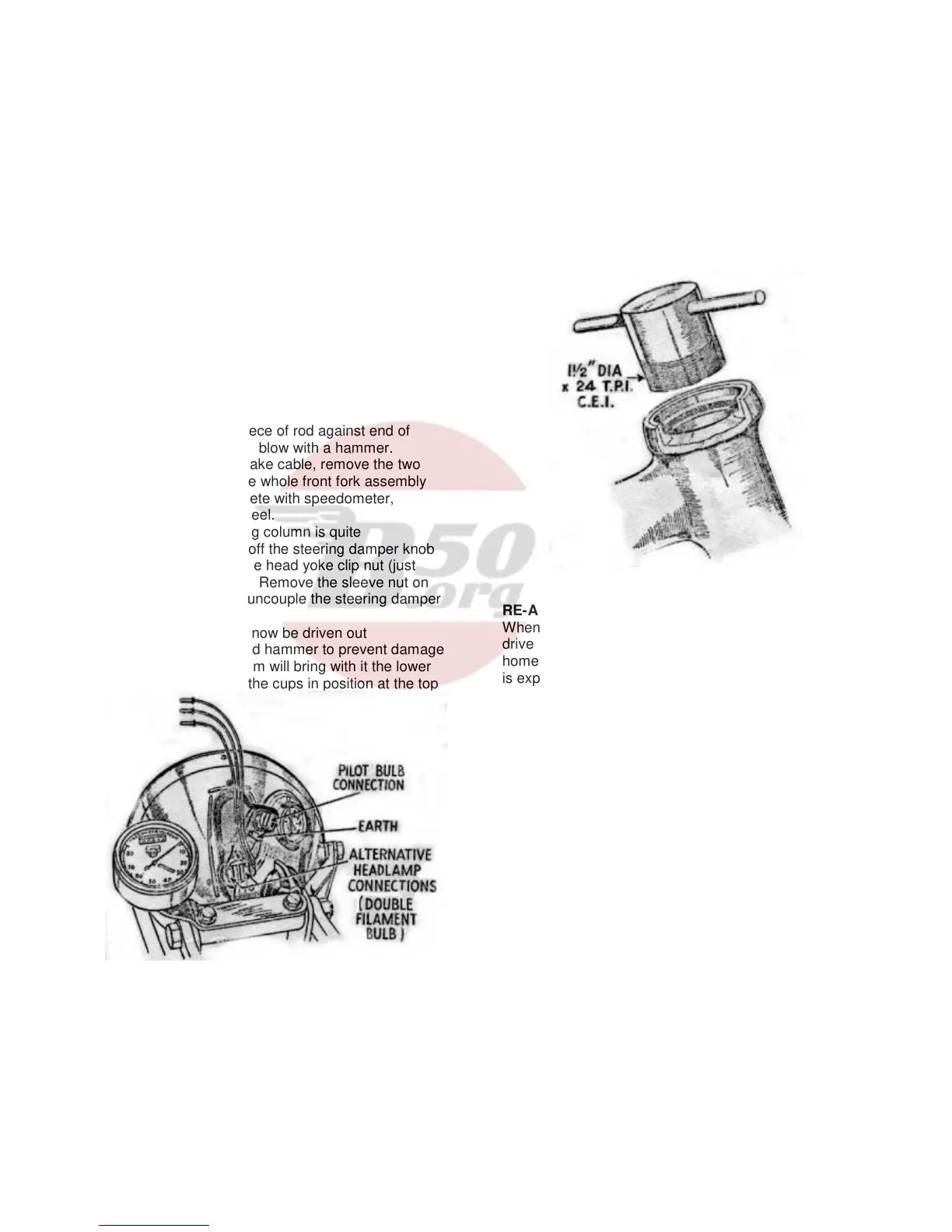

and bottom of the steering head. A simple extractor

shown in Fig. 42 is used for the removal of these

cups. They are threaded to take the extractor, which

should be screwed well home, since it engages with

a few threads only. A bar is then inserted from the

opposite end of the head lug, and the extractor and

ballrace driven out together.

If the balance cups and cones are pitted, to even a

slight degree, they must be replaced, otherwise the

steering will be uncomfortable. Note that the pitting

is invariably due to “hammering” of the balls in their

tracks, due to slack adjustment in the first place.

Fig. 42. Steering head ballrace extractor.

RE-ASSEMBLY

When fitting new ballrace cups make sure they are

driven in squarely and that they are pressed well

home. Replace the steering stem and if any difficulty

is experienced in making the balls (of which there are

20 top and 20 bottom – all ¼ “) stay in position, the

tracks should be heavily smeared with grease.

Refit the dust cover and steering head yoke, followed

by the top sleeve nut. The latter may now be

tightened, until there is no trace of play in the head.

On the other hand, do not tighten excessively.

Replace the steering damper rod, complete with

plates, from below and tighten the damper plate

securely to the frame. The lower end of the steering

damper rod is slotted to take the fork link bolt, and

care must be taken to see that the rod is fitted so that

the link bolt can slide through.

The fork spring should be carefully inspected. If it is

suspected as having been weak through prolonged

use over bad roads, or shows signs of collapse, a

new one should be fitted. Attach the spring to its

bottom scroll, and replace the bottom two fork links

loosely in position. Refit the top scroll in position,

draw the wiring to the headlamp forward to it’s

normal position, and assemble the top fork links.

Adjustment of the links should be such that there is

no side play present. The headlamp connections are

shown in Fig. 41.

Loading...

Loading...