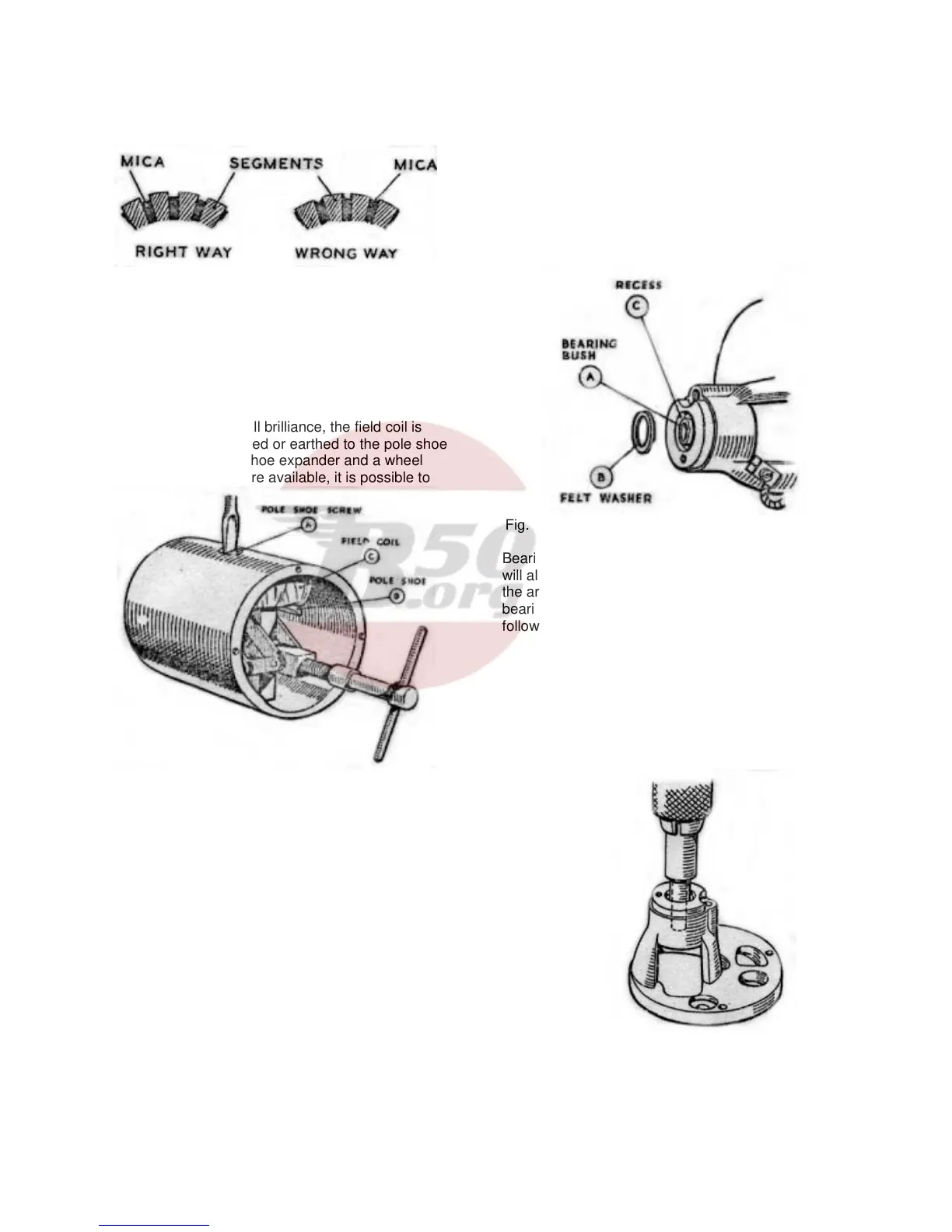

Undercut the mica insulation between the segments

to a depth of 1/32” (fig. 61) with a hacksaw blade

ground down until it is only slightly thicker than the

mica.

Fig. 61. Method of undercutting mica.

B (6) Dynamo – Field Coil

(a) Test the field coil by connecting it in series with a

six volt battery and a six volt, three watt bulb. If the

field coil is satisfactory, the bulb will light up, but its

brilliance will be somewhat less than when connected

direct to the battery. Failure of the bulb to light

indicates an open circuit in the field winding, while if

the bulb lights up will full brilliance, the field coil is

probably either shortened or earthed to the pole shoe

or dynamo yoke. If a shoe expander and a wheel

operated screwdriver are available, it is possible to

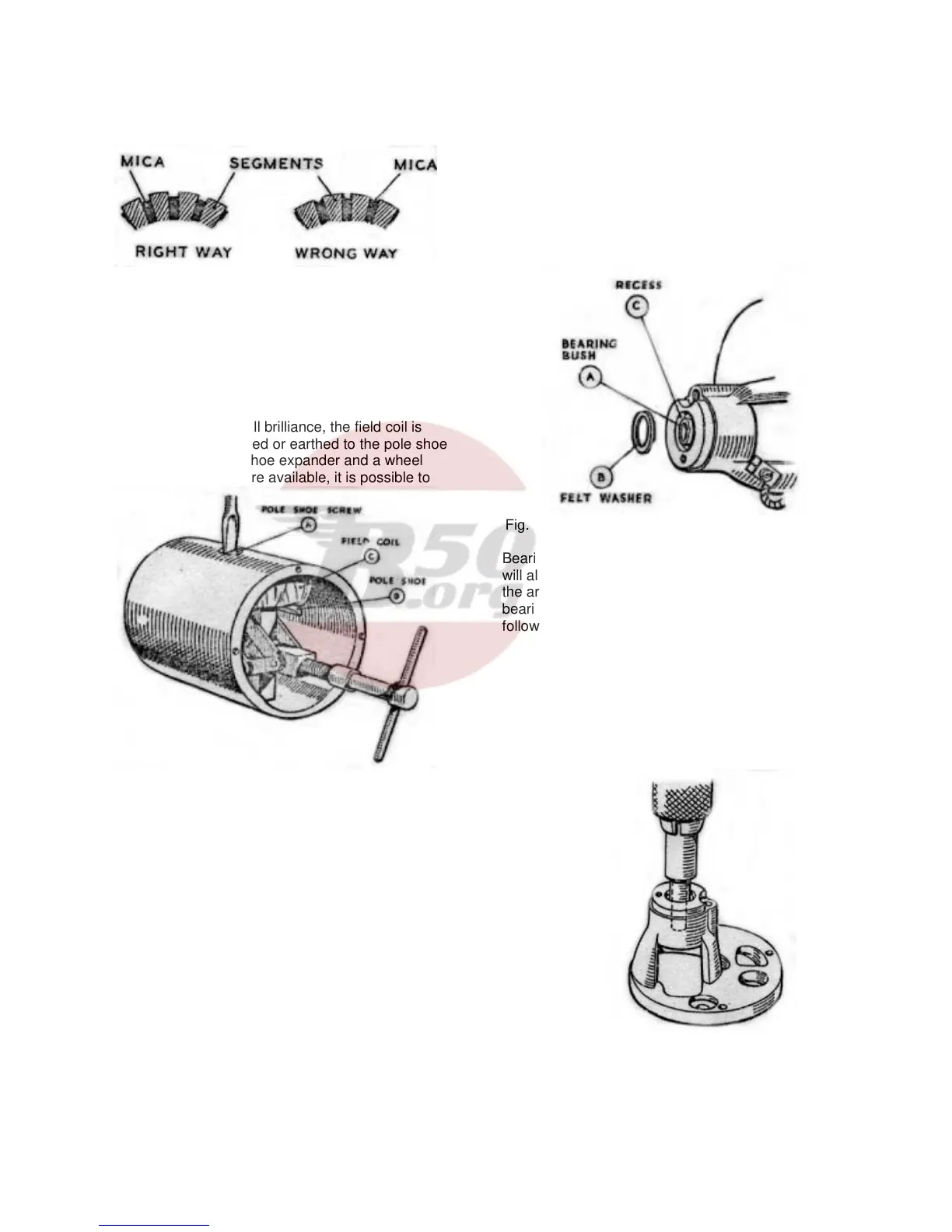

Fig. 62. Pole shoe and field coil assembly.

replace the field coil. A pole shoe expander is

necessary to ensure there will not be any airgap

between the pole shoe and the inner face of the

yoke.

(b) Replace the field coils as follows:-

(c) Unscrew the pole shoe retaining screw (A, Fig.

62) by means of the wheel operated screwdriver.

(d) Draw the pole shoe (B) and field coil (C) out of the

yoke and lift off the coil.

(e) Fit the new field coil over the pole shoe and place

it in position inside the yoke. Take care to ensure

that the taping of the field coil is not trapped between

the pole shoe and the yoke.

(f) Locate the pole shoe and field coil by lightly

tightening the fixing screw. Insert the pole shoe

expander, open it to its fullest extent and tighten the

screw. Remove the expander and give the screw a

final tightening with the wheel operated screwdriver.

Caulk the screw to lock it in position.

Dynamo - Armature

The testing of the armature winding requires the use

of a volt-drop test or a growler. If these are not

available, the armature should be checked by

substitution. No attempt should be made to machine

the armature core or to true a distorted armature

shaft.

B (8) Dynamo – Bearings.

A ball bearing is fitted at the driving end and a plain

porous bronze bearing bush at the commutator end.

Fig. 63. Commutator end bracket with bearing bush.

Bearings which are worn to such an extent that they

will allow approximately .015” total side movement of

the armature shaft must be replaced. To replace the

bearing bush at the commutator end, proceed as

follows:-

(a) Press the bearing bush (A, Fig. 63) out of

the commutator end bracket and remove the

felt ring (B).

(b) Press the new bearing bush into the end

bracket using a shouldered mandrel of the

same diameter as the shaft which is to fit in

the bearing. Note: Before fitting the new

bearing bush it should

Fig. 64 Fitting bearing bush using a shouldered

mandrel.

Be allowed to stand for 24 hours immersed

for about 7/8ths of its length in thin engine

oil. The

40

Loading...

Loading...