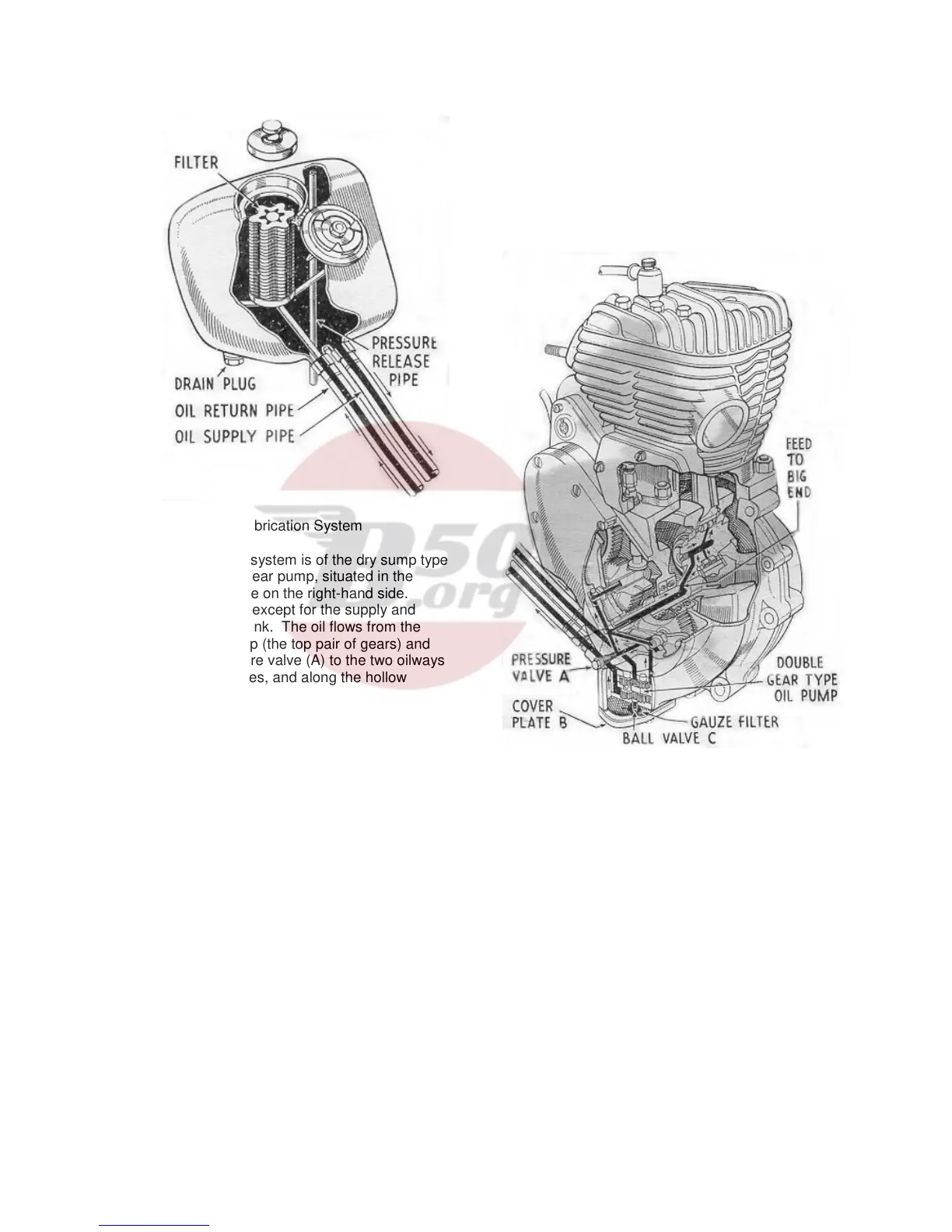

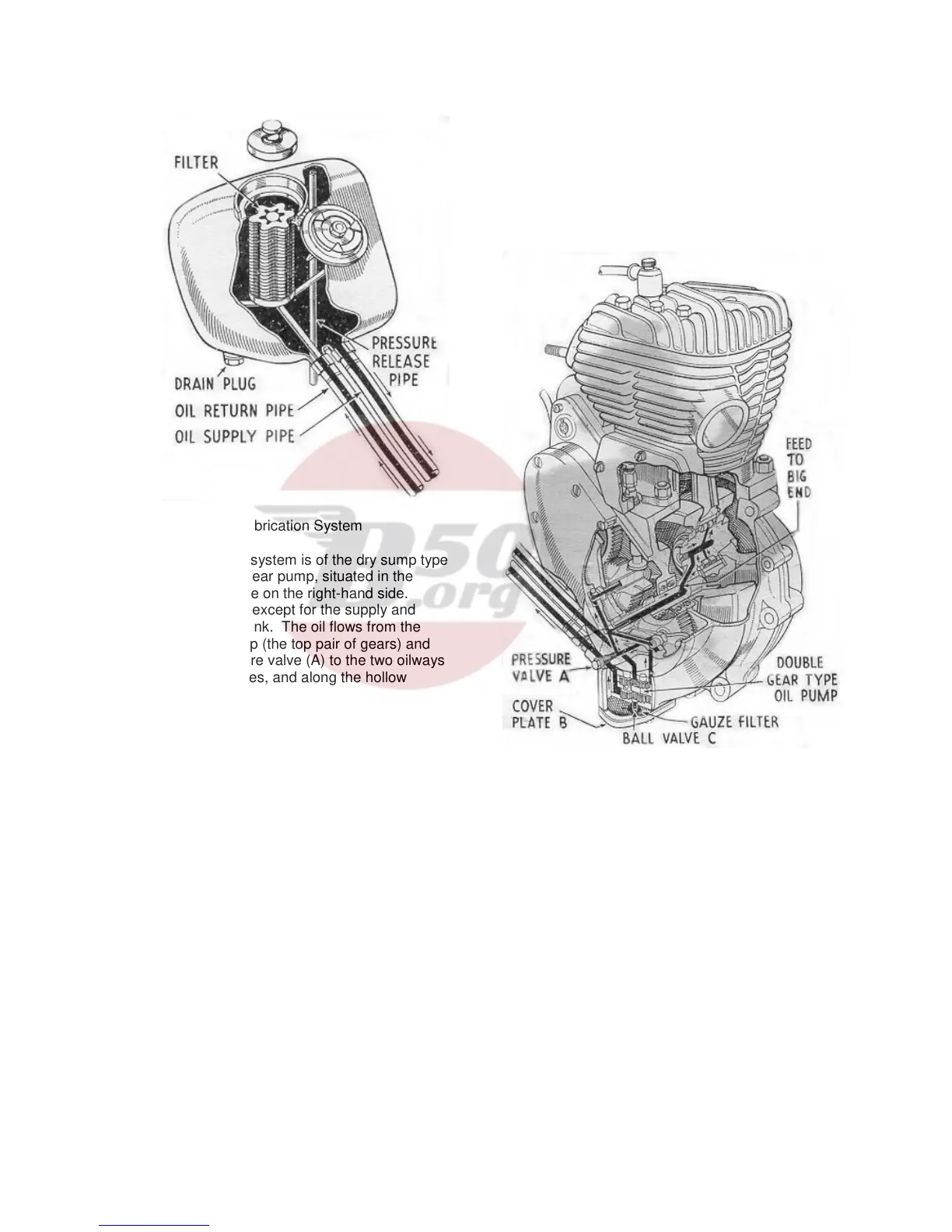

THE LUBRICATION SYSTEM

Fig. 1. Lubrication System

The engine lubrication system is of the dry sump type

operated by a double gear pump, situated in the

bottom of the crankcase on the right-hand side.

All oilways are internal except for the supply and

return pipes from the tank. The oil flows from the

tank to the supply pump (the top pair of gears) and

thence past the pressure valve (A) to the two oilways

feeding the cam spindles, and along the hollow

mainshaft to the big end bearing. After lubricating

the big end and circulating through the engine in the

form of a mist, the oil drains down through a filter in

the bottom of the crankcase, from which it is drawn

by the return pump (lower pair of gears) past ball

valve (C), and delivered up the return pipe to the

tank, where it passes through a fine mesh filter into

the tank itself.

Incorrect seating of the ball valve (A), will allow oil to

transfer from the tank to the engine, whilst the

machine is stationary. If the ball valve (C) should get

stuck in its seating, there will be no return of oil to the

tank. To check the oil circulation open the tank filler

cap and remove filter cap whilst the engine is

running. Oil should be seen issuing from the return

pipe from the crankcase. The tank and crankcase

should be drained every 2,000 miles and replenished

with clean oil.

Any restriction in the pressure release pipe in the

tank will cause an increase in pressure inside the oil

tank, and will result in leakage of oil at the filler cap.

This can be put right by inserting a length of flexible

wire into the pipe at its lower end (just in front of the

rear mudguard) and pushing the wire right up the

pipe, thus clearing any obstruction.

To remove the oil tank filter for cleaning, release the

tank filler cap, release the filter tap thus exposed, and

lift filter out. The filter should be placed in a can large

enough to cover it with petrol, and thoroughly

washed. Before replacing make sure that it is quite

dry of petrol.

The pump filter can be withdrawn after removing the

cover plate (B) and should be thoroughly washed

with petrol, dried and replaced.

NOTE. It is not advisable to remove the oil pump

unless the pump is definitely faulty.

3

Loading...

Loading...