REMOVING, DISMANTLING AND RE-ASSEMBLY OF

THE GEARBOX AND GEAR CHANGE

REMOVAL

Instructions as to the procedure to be adopted for

removal of the chaincase and clutch are contained in

the Chapter on “Dismantling and Re-assembly of the

Clutch.” In this case, however, there is no need to

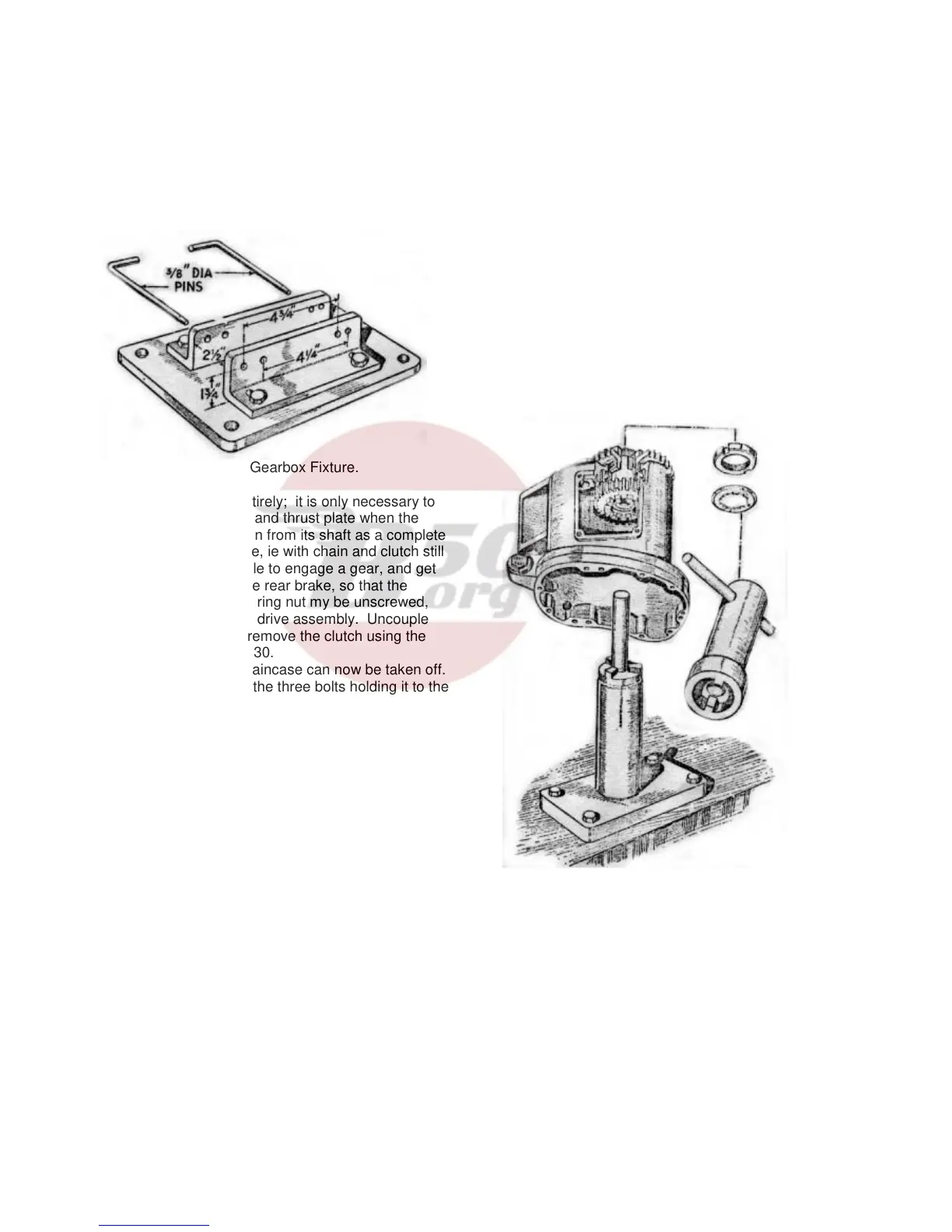

Fig. 33. Gearbox Fixture.

dismantle the clutch entirely; it is only necessary to

take off the cover plate and thrust plate when the

clutch may be withdrawn from its shaft as a complete

unit. Before this is done, ie with chain and clutch still

in position, it is advisable to engage a gear, and get

an assistant to apply the rear brake, so that the

engine shaft cush drive ring nut my be unscrewed,

thus releasing the cush drive assembly. Uncouple

the primary chain and remove the clutch using the

extractor shown in Fig. 30.

The inner half of the chaincase can now be taken off.

Note that in addition to the three bolts holding it to the

crankcase, there is a nut attaching the rear

chainguard to the chaincase and this must also be

removed. Access to the nut will be made much

easier if the three crankcase bolts are unscrewed first

and the chaincase pulled off the crankcase register.

The oil tank breather pipe is next to be removed and

this is only a matter of releasing the clip bolts.

Turning now to the right-hand side of the machine,

first take off the footrest, then uncouple the clutch

cable from its operating arm and unscrew the cable

adjuster from the gearbox.

In order that the bolts which hold the gearbox to the

yoke plates may be removed it is necessary to take

off the exhaust pipe and silencer.

The box itself can be prised upwards out of the yoke

plates. If the latter grip the gearbox lugs too tightly

for this to e carried out easily, slacken the bolts and

studs which clamp the yoke plates to the crankcase.

No difficulty should then be experienced in removing

the gearbox.

DISMANTLING THE GEARBOX

It will greatly help work on the gearbox I it is held in a

simple fixture such as that illustrated in Fig. 33. The

device can be made from suitable pieces of angle

iron, spaced to suit the gearbox lugs. If it is not

possible to make the fixture, gearbox can be held in a

vice.

Commence dismantling by taking off the rectangular

inspection cover and follow this with kickstarter

crank. The latter if fixed by means of a cycle type

cotter. The foot change pedal is held in position by

means of a pinch bolt which must be slackened off

before the pedal can be removed. Behind this pedal

are two circlips, the larger one being removed,

followed by the gear indicator disc. Leave the small

circlip in position for the time being.

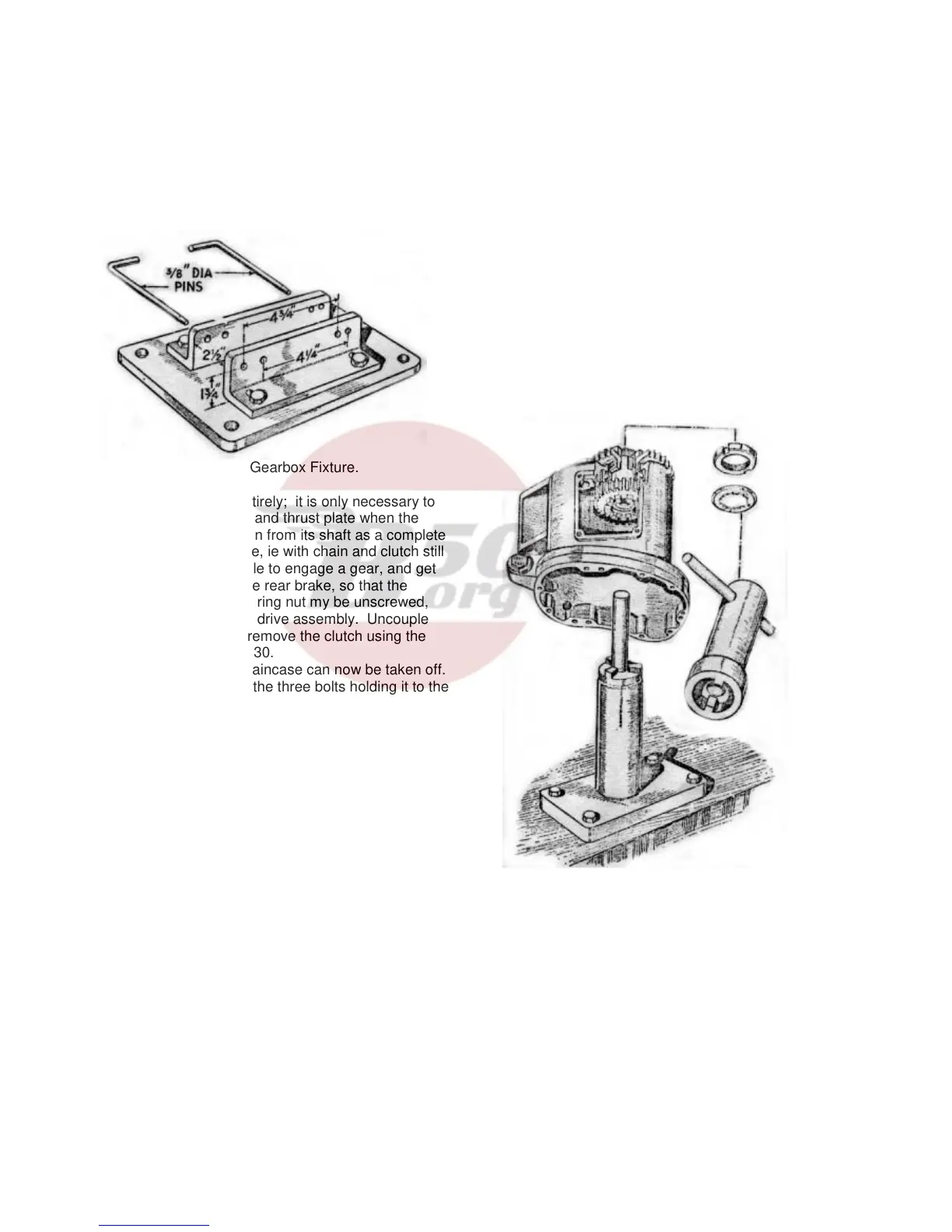

Fig. 34. Pinion sleeve removal tool.

The gearbox outer cover is now ready for removal. It

is held on seven cheese head screw and, on the face

behind the gear change mechanism, by three bolts

and on nut. When the outer cover is taken off, it will

contain the kickstarter quadrant and spring, but these

need not be disturbed unless obviously requiring

attention.

23

Loading...

Loading...