29 CHAIN ALTERATIONS AND REPAIRS

A chain rarely breaks if it is kept properly lubricated

and adjusted. Usually it is worn out long before it

reaches breaking point. The rear chain is the most

heavily stressed and is therefore the one most likely

to give trouble. Spare parts are carried to enable the

rider to carry out a repair on the road with the aid of a

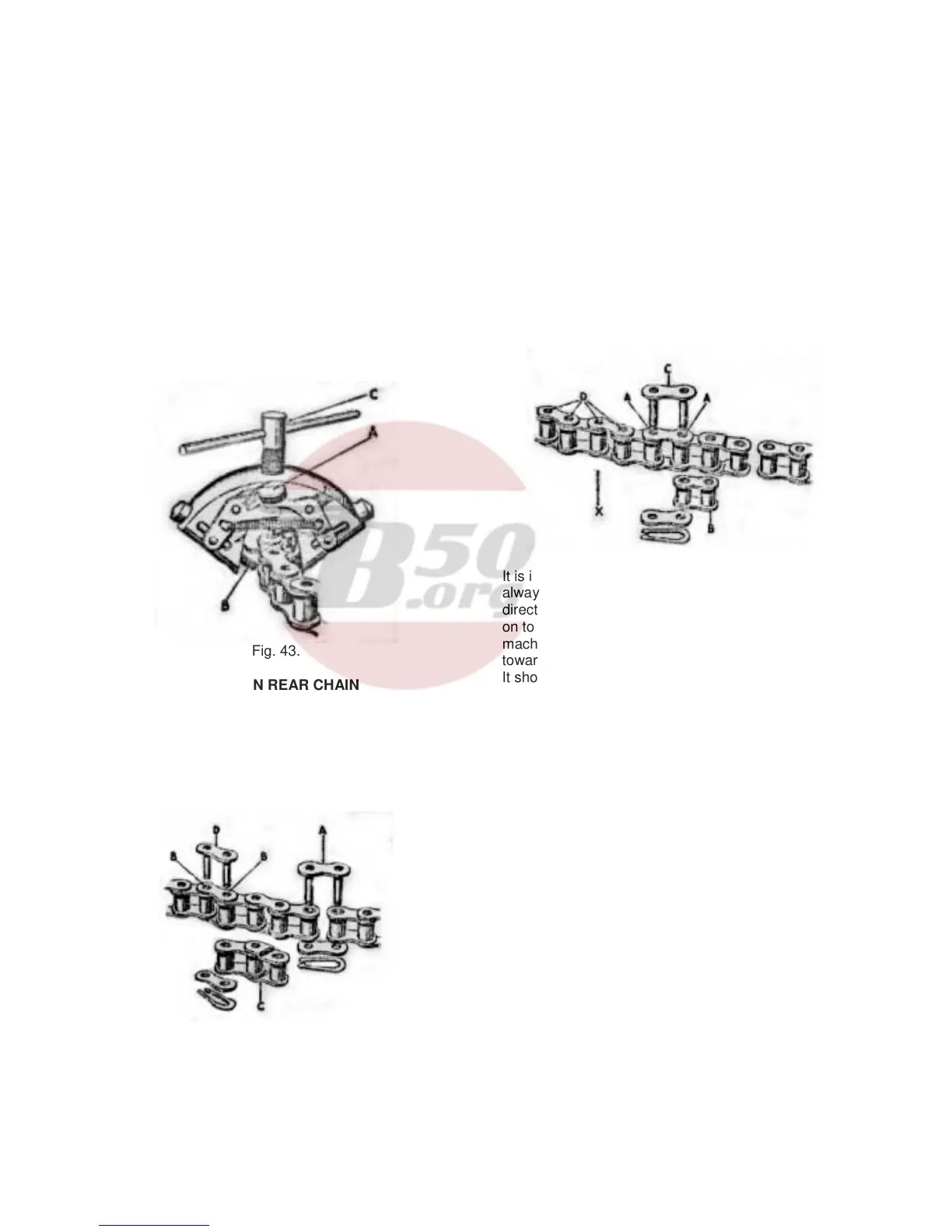

chain rivet extractor (see Fig. 43). The front chain

will probably be worn out before it requires

shortening.

HOW TO USE THE CHAIN RIVET EXTRACTOR

First press down lever A (Fig. 43) to open the two

jaws (B). Insert the link to be removed so that the

jaws grip the roller and support the uppermost inner

side plate. The Punch (C) is then screwed down on

to the rivet head until the rivet is forced through the

outer plate.

Fig. 43.

TO SHORTEN A WORN REAR CHAIN

After a big mileage, the rear chain may have

stretched so that no further adjustment is possible by

the usual method (described on page 20). In this

case it is possible to shorten the chain by one link or

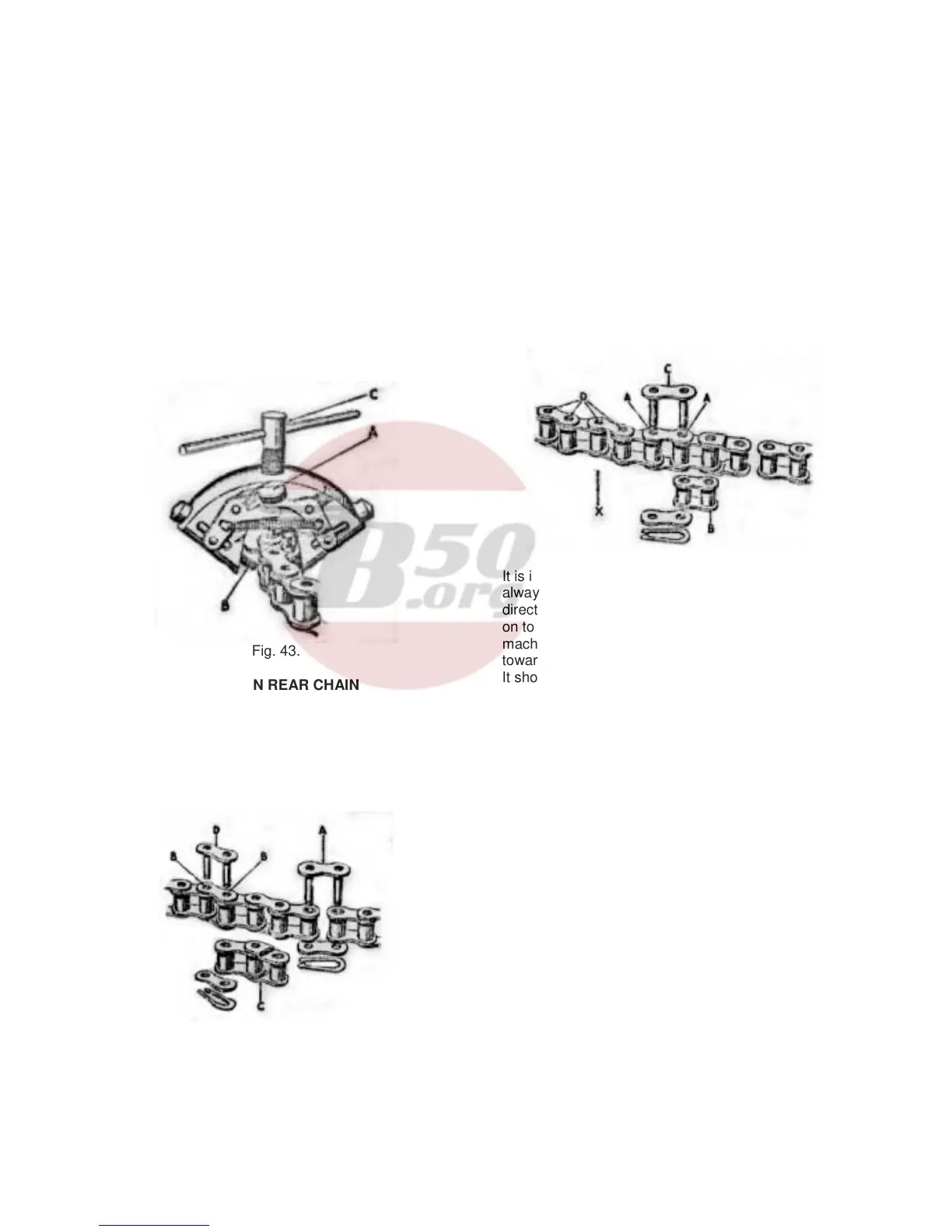

pitch, so increasing its useful life. First remove the

single connecting spring link (A) securing the two

ends of the chain (Fig. 44). If the chain terminates in

Fig. 44.

two ordinary links as in Fig. 44 (in which case the

chain will be of an even number of pitches) extract

the third and fourth rivets (B) from the end and

replace the detached three pitches by a single

connecting link (C). The connection is made with an

additional spring link (D). If one end of the chain has

a double cranked link (Fig. 45) – in which case the

chain will have an odd number of pitches – extract

the second and third rivets (A), releasing the cranked

link unit complete, which can be retained for future

use. Replace the one inner link (B) and again

connect up with an additional single connecting link

(C).

TO REPAIR A DAMAGED CHAIN

If a roller or link has been damaged (X, Fig. 45)

remove rivets (D), take out the damaged link and

replace with one inner link, secured by two single

connecting links.

Fig. 45.

It is important that the spring clip fastener should

always be put on so that the CLOSED end faces the

direction of travel of the chain – i.e., when the clip is

on top run of chain closed end is towards front of

machine – when clip is on bottom run, closed end is

towards rear of machine.

It should be noted that once a rivet has been

extracted it must not be used again, so that it is

important to check that the correct rivet is being

removed before actually removing it. In the case of

double cranked links, the complete unit comprises an

inner link and the cranked outer link – three rollers in

all – and these must never be separated.

FITTING REAR CHAIN

To fit a new rear chain, turn wheel until the spring link

of the old chain is located on rear sprocket.

Disconnect and allow the lower run to drop down.

Join the top run of the old chain to the new chain by

means of the connecting link, and then by pulling on

the bottom run of the old chain the new one will be

carried around gearbox sprocket. Then the old chain

can be disconnected and the ends of the new one

joined together.

When the rear chain breaks and falls from its

sprockets, the new or repaired chain can be replaced

without taking off chainguards. One end of the chain

must be fed (from the rear) under the front end of the

rear top chainguard on to the gearbox sprocket. A

long bladed screwdriver or a piece of stiff wire may

assist this operation. When

30

Loading...

Loading...