A (10) Removal from engine

Before the magdyno can be removed from the

engine, it is first necessary to take off the timing

cover. With this removed, the magdyno pinion must

next be withdrawn from the shaft by means of the

extractor shown in Fig. 10. There is a special oil seal

washer fitted behind the pinion – see that this is not

lost. Now release the straps holding the magdyno on

its platform, and the whole instrument can be lifted

off.

Retain any shims which may have been fitted under

the base and replace when refitting magdyno.

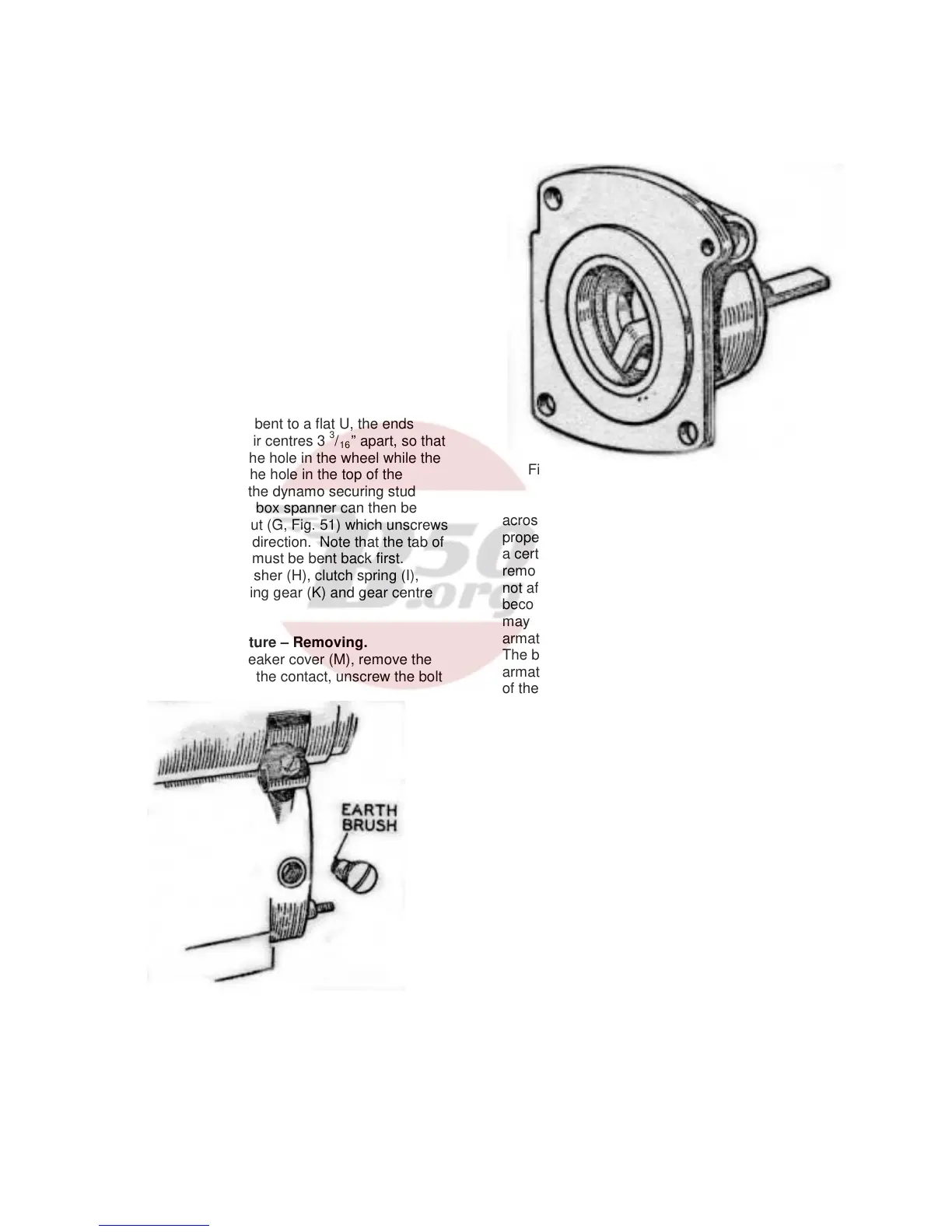

A (11) Magneto dismantling.

Remove the dynamo (E, Fig. 51) and take off the

driving end cover (F) by unscrewing the four

countersunk head screws. To dismantle the slipping

clutch it will be necessary to use a jig (Fig. 50) to hold

the larger gear whilst the securing nut is being

undone. This consists simply of a length of ¼ “

diameter mild steel rod bent to a flat U, the ends

being cut short with their centres 3

3

/

16

” apart, so that

one can be slipped in the hole in the wheel while the

other is engaged with the hole in the top of the

casting through which the dynamo securing stud

usually goes. The

7

/

16

” box spanner can then be

used on the securing nut (G, Fig. 51) which unscrews

in the normal left-hand direction. Note that the tab of

the locking washer (H) must be bent back first.

Remove the locking washer (H), clutch spring (I),

friction washer (J), driving gear (K) and gear centre

(L).

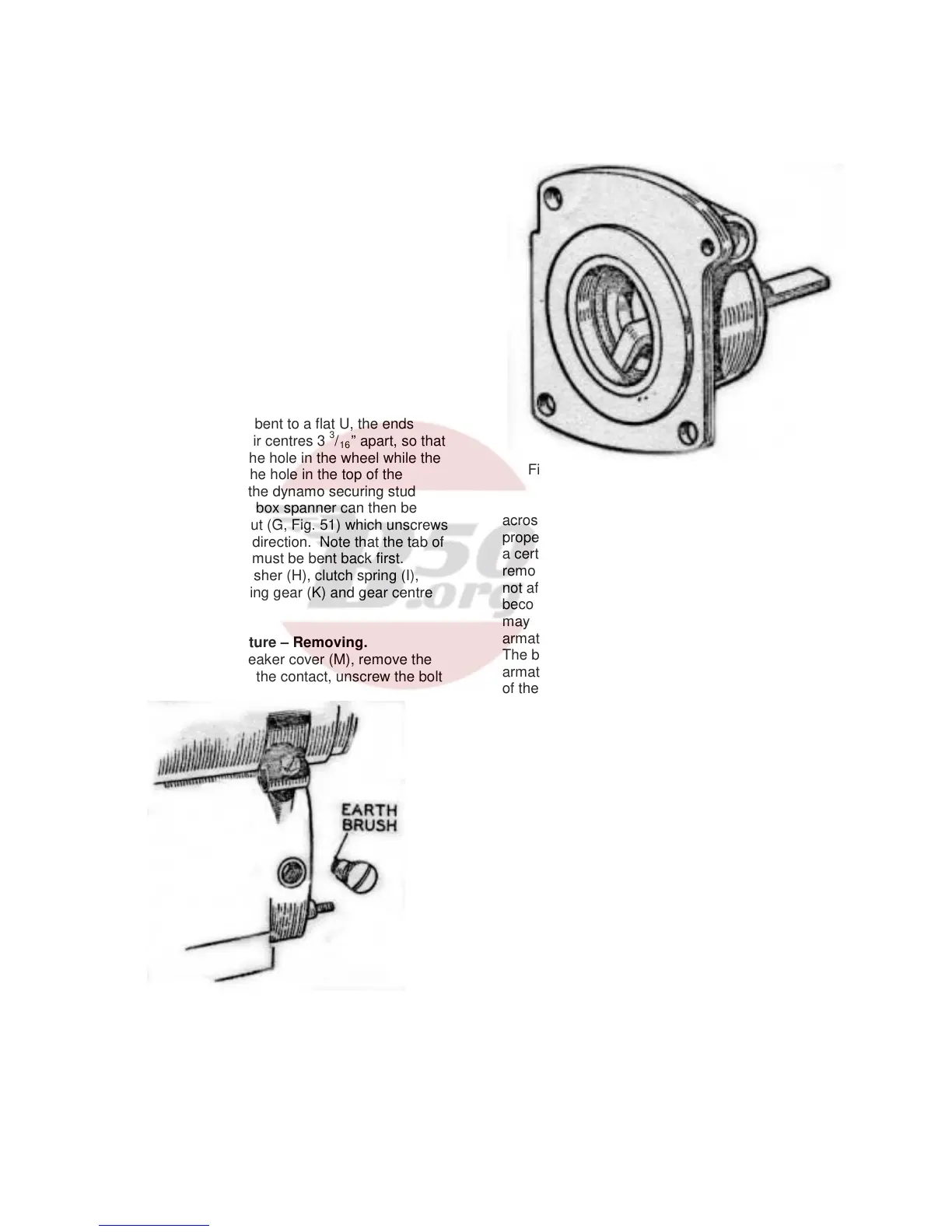

A (12) Magneto Armature – Removing.

Take off the contact breaker cover (M), remove the

spring arm (N) carrying the contact, unscrew the bolt

(O) securing the contact breaker (P) and draw the

Fig. 52. Magneto earthing brush.

contact breaker off the shaft. Spring the wire ring

(Q), securing the cam (R), out of its location in the

contact breaker housing and remove the cam.

Unscrew the cable stop (S) of the timing control and

remove the control plunger (T). Remove the pick-up

holder and the small earthing brush (Fig. 52) which

will be found on the side of the magdyno. Unscrew

the screws (U, Fig. 51), earthing terminal (V), and

pillar (W) from the contact breaker end plate (X) and

remove the plate from the magdyno, together with

shims (Y). The armature (Z) can then be drawn out

of the machine. There is no need to put a keeper

Fig. 53. Method of removing outer journals of

bearings.

across the magnet as it retains its magnetic

properties more or less indefinitely. Although it loses

a certain immaterial amount of power in the first

removal of the armature, subsequent removals do

not affect it. Do not allow the magneto body to

become in close contact with any iron filings as they

may become attracted to the magnet and cause the

armature to bind.

The ballraces can be removed from the magneto

armature shaft by means of an extractor, while a tool

of the type shown should be used to remove the

outer journals (Fig. 53).

A (13) Magneto Armature Testing.

If test apparatus is not available, a rough check of the

armature windings can be made by means of a two

volt battery (a tapping across one cell of the motor

cycle battery), and an ammeter. Screw the contact

breaker retaining screw (O, Fig. 51) into the end of

the armature shaft. Connect one terminal of the

battery, with the ammeter in series, to the screw.

Connect the other battery terminal to the metal body

of the armature. The ammeter will then record the

current taken by the primary winding – this should be

approximately four amperes. To check the

secondary winding of the armature, wrap the bared

end of a length of H.T. cable round the brass insert of

the slip ring and hold the other about one-eighth from

the armature core. If the lead from the battery which

was connected to the core is then flashed quickly on

and off the core, a spark should occur between the

H.T. cable and the core.

No spark at these points indicates a fault either in the

armature windings or in the condenser and a

replacement armature must be fitted.

36

Loading...

Loading...