Fig. 75. Headlamp, type DU42 with reflector partially

removed.

panel can be removed when the three fixing screws

are withdrawn. The ends of all the cables are

identified by means of coloured sleevings. The

colour scheme and the diagram of connections are

shown in the wiring diagram. When making

connections to the switch, bare the end of the cable

for about 3/8”, twist the wire strands together and

turn back about 1/8” so as to form a small ball.

Remove the grub screw from the appropriate terminal

and insert the wire so that the ball fits in the terminal

post. Now replace and tighten the grub screw; this

will compress the ball to make a good electrical

connection.

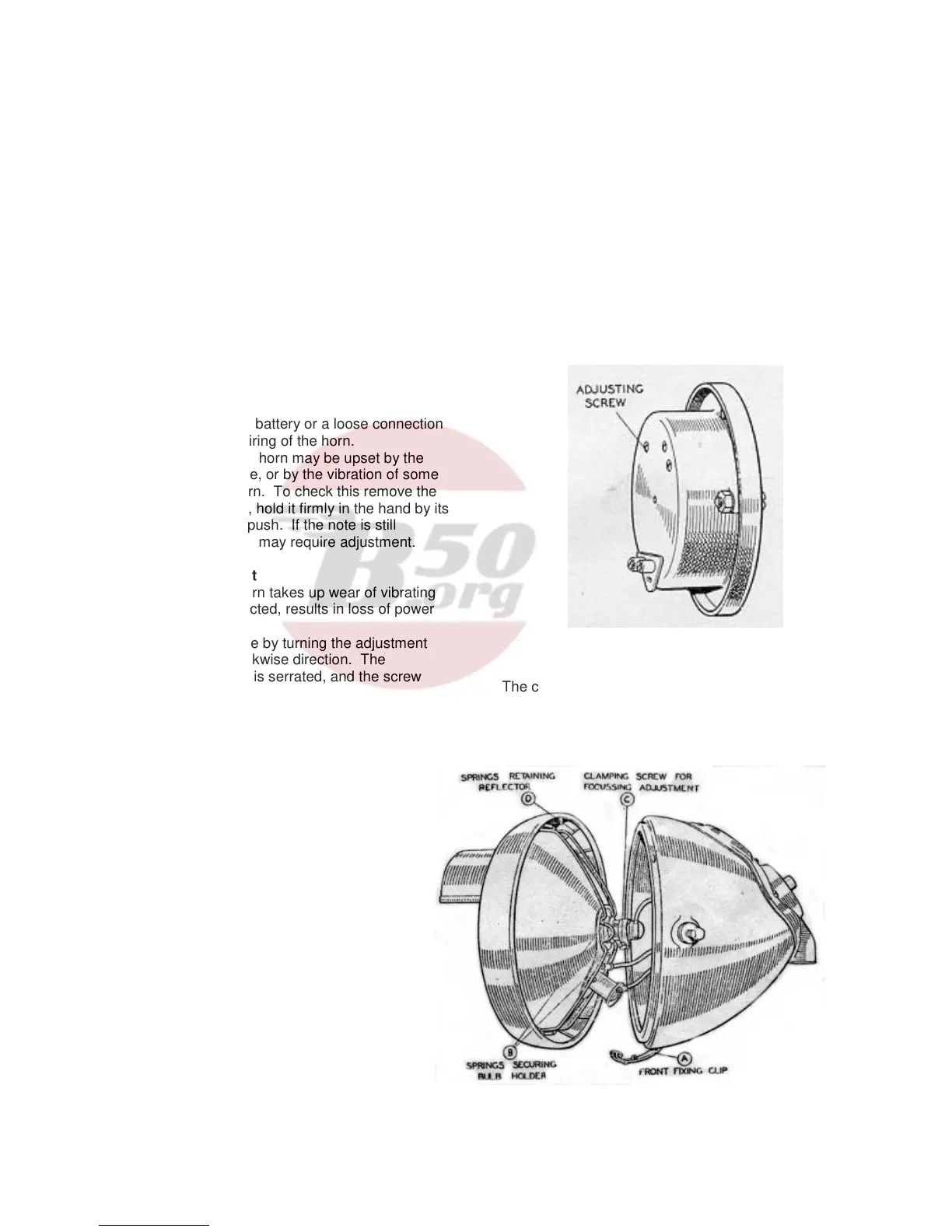

C (5) Horn, Type HF1235

Electric horns are adjusted to give their best

performance before leaving the works and will give a

long period of service without any attention. If the

horn becomes uncertain in action or does not vibrate,

it has not necessarily broken down. The trouble may

be due to a discharged battery or a loose connection

or short circuit in the wiring of the horn.

The performance of the horn may be upset by the

fixing bolt working loose, or by the vibration of some

part adjacent to the horn. To check this remove the

horn from its mounting, hold it firmly in the hand by its

bracket and press the push. If the note is still

unsatisfactory, the horn may require adjustment.

Method of Adjustment

The adjustment of a horn takes up wear of vibrating

parts which if not corrected, results in loss of power

or roughness of tone.

The adjustment is made by turning the adjustment

screw, usually in a clockwise direction. The

underside of the screw is serrated, and the screw

must not be turned for more than two or three

notches before retesting. If the adjustment screw is

turned too far in a clockwise direction, a point will

occur at which the armature pulls in but does not

separate the contacts.

When testing do not continue to operate the push if

the horn does not sound. If when the push is

operated, the horn does not take any current

(indicated by an ammeter connected in series with

the horn), it is possible that the horn has been

adjusted so that its contact breaker is permanently

open.

After adjusting, note the current consumption. A horn

may give a good note, yet be out of adjustment and

taking an excessive current. When adjusting, do not

attempt to unscrew the nut securing the tone disc or

any other screw in the horn.

Fig. 71. Horn showing adjusting screw.

The current, when the horn is adjusted to give its

best performance must not exceed 4-5 amperes.

---------------------------

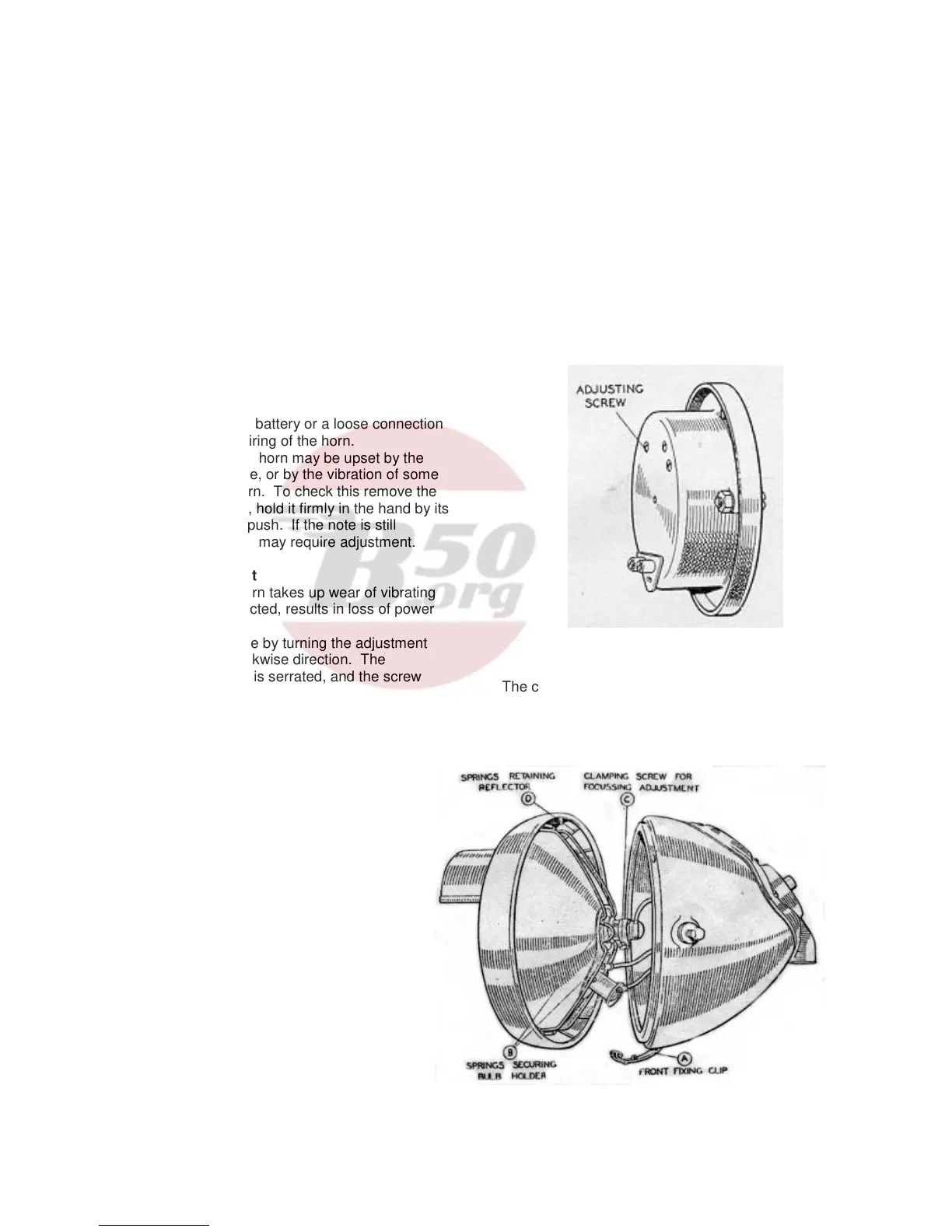

C (6) Headlamp, Type DU 42. Fitted to

later models.

The headlamp incorporates the main bulb (6

volt 24 watt S.B.C. double contact, double

filament type) and the pilot bulb (6 volt 3 watt

S.B.C. centre contact type).

It differs from the type described in Section C

(1), page 44, in that the ammeter is omitted

and the main lighting switch is removed from

the lamp and is mounted on a separate

bracket. The lamp is fitted with a push

operated switch by means of which the rider

can change from the main bulb to the pilot

bulb or vice versa.

The method of removing the front and reflector

and of setting the focussing remains as

described in Section C (1), page 44.

45

Loading...

Loading...